Plastic bottle

a bottle and plastic technology, applied in the field of plastic bottles, can solve the problems of reducing the strength of the bottle, unable to stand up to distribution, and becoming extremely difficult for consumers to hold, and achieve the effect of facilitating holding and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

exemplary embodiment 1

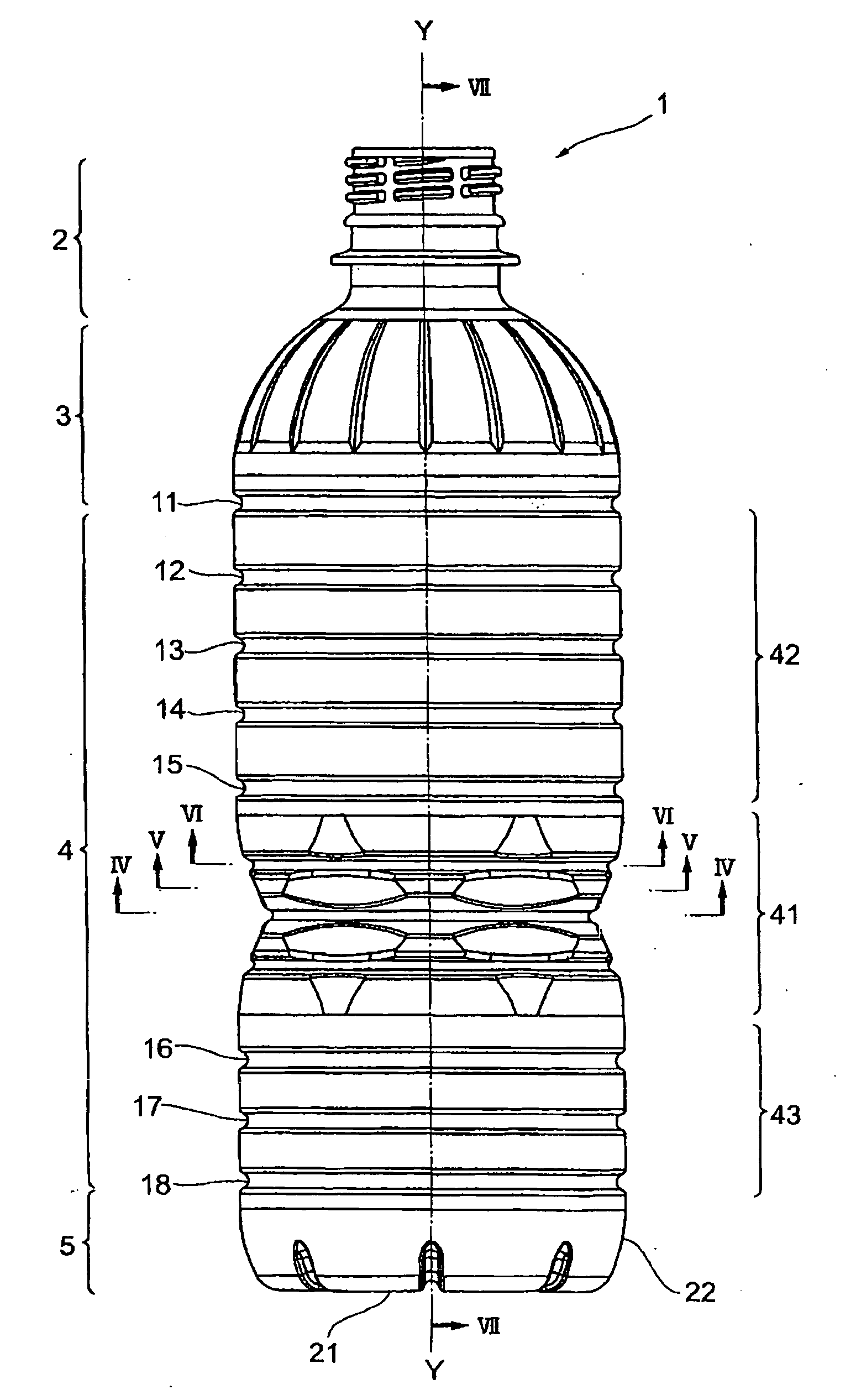

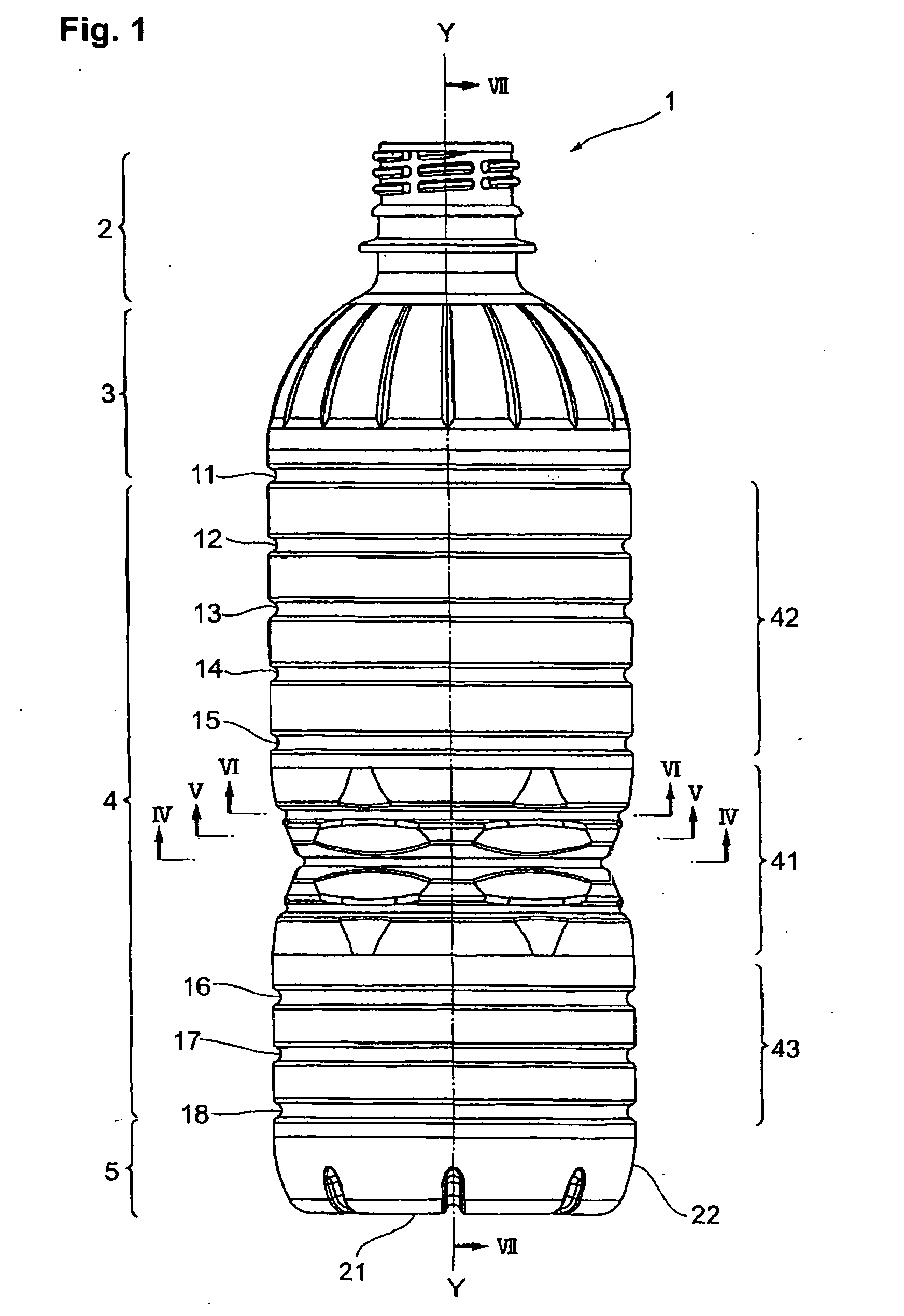

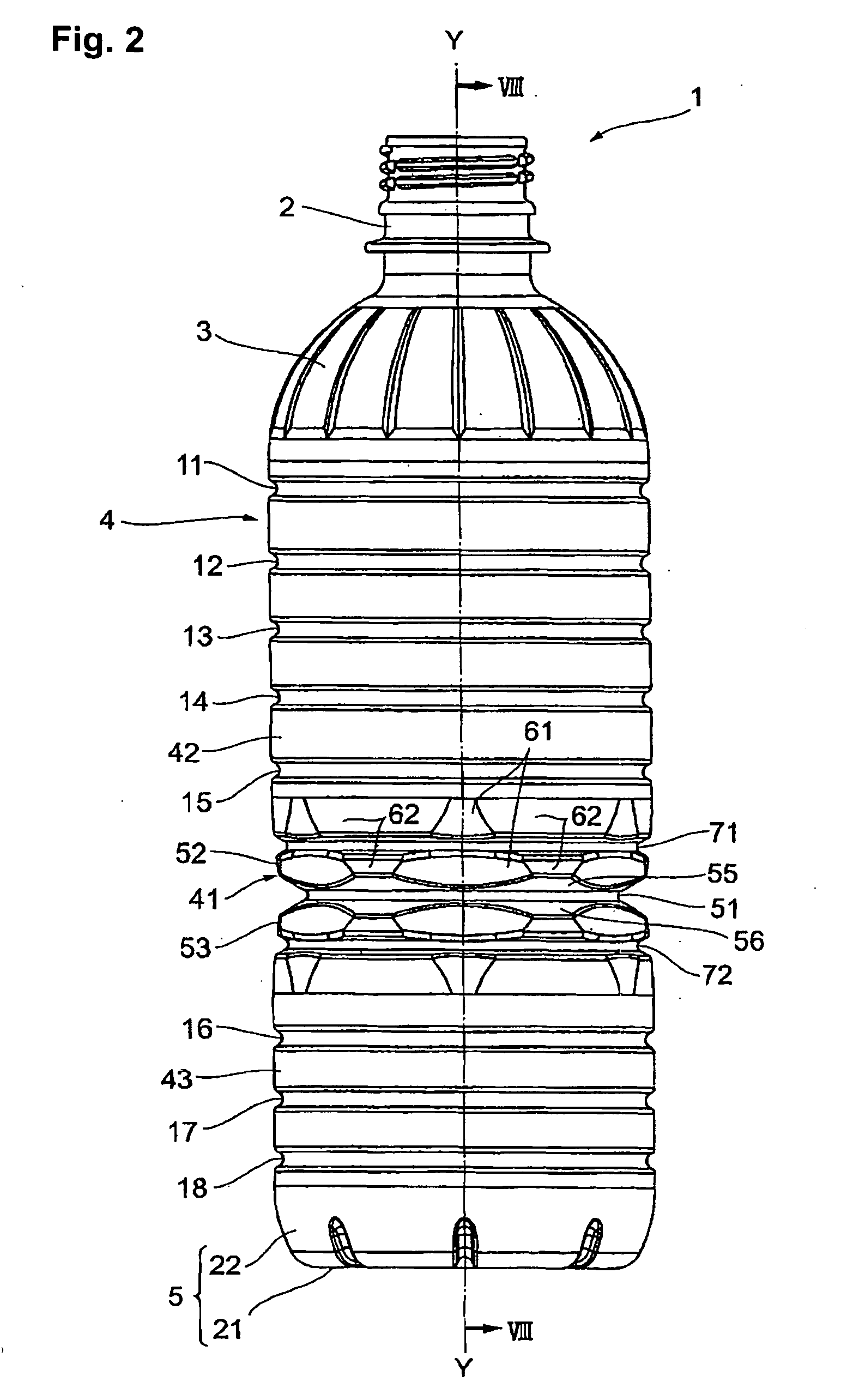

[0033]As shown in FIGS. 1 and 2, a plastic bottle 1 is formed by a stretch forming method such as biaxial stretch blow molding, using a thermoplastic resin such as polyethylene, polypropylene, or polyethylene terephthalate as a primary material. An exemplary version of bottle 1 may have a weight of approximately 18g, a height of approximately 200 mm, and a fully filled capacity of approximately 570 ml.

[0034]Bottle 1 may be washed and sterilized after molding, then filled with a beverage. Exemplary beverages that may be contained in bottle 1 include water, green tea, oolong tea, juice, and other non-carbonated beverages. In general, the internal pressure in the bottle is negative with non-carbonated beverages, making bottle strength weak. To provide strength, concave rib(s) may be formed on the disclosed bottle. For example, in embodiment 1, bottle 1 may have concave ribs 11-18 described below and may, therefore, be appropriate for filling with a non-carbonated beverage. In some case...

exemplary embodiment 2

[0050]FIGS. 9 through 13 illustrate a bottle 100 according to a second embodiment. The main point of difference vs. embodiment 1 discussed above is the constitution of the constricted portion. Below we assign the same reference numerals to those parts of embodiment 2 which are the same as in embodiment 1.

[0051]Bottle 100 may include a constricted portion 110, which may have an approximately dodecagonal cross-sectional shape. The cross-sectional shape is described as “approximately” dodecagonal for the same reason as explained above with respect to embodiment 1. In other embodiments, the cross-sectional shape of constricted portion 110 may approximate polygons other than a dodecagon. Unlike constricted portion 41 in embodiment 1, embodiment 2 does not include circumferential ribs formed on constricted portion 110.

[0052]Constricted portion 110 may have upper and lower polygonal surfaces 112 and 113 centered around a most-constricted, deepest portion 111. As shown in FIG. 13, the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com