Intraocular thin lens for anterior chamber installation

a thin lens and anterior chamber technology, applied in the field of intraocular lens, can solve the problems of reducing the overall dimension of the iol, ophthalmic surgeons into tolerable compromises, and the lenticular elements, whatever their size, are still subject to various spherical and thickness aberrations which are not easily corrected, so as to reduce the risk of closure, prevent any pressure on the iris, and eliminate the risk of cataract or iris pigment dispersion

Inactive Publication Date: 2009-07-16

NORDAN LEE T +1

View PDF19 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This patent describes an innovative intraocular lens (IOL) designed for use during surgery. It has several technical benefits compared to previous devices: it is easy to install, reduces complications like glare and poor night vision, and does not require significant modification after placement. The lens consists of a thin layer made of flexible material that passes through a small opening in the cornea without applying much pressure on the surrounding tissues. It also includes a unique structure called a diffractive phase Fresnel-type lens that helps improve image quality. Additionally, the lens can have various levels of power to address common refractive errors. Overall, this new technology provides better outcomes and minimizes risk associated with ophthalmic procedures.

Problems solved by technology

The technical problem addressed in this patent text relates to developing an intraocular lens (IOL) that can be implanted without requiring a complex multi-piece design or minimizing its effectiveness due to limitations on its size. Current conventional IOLs require precise fitting based on the size of the patient's eye, leading to potential visual difficulties if there is no close fit. Additionally, current IOL designs often result in unwanted astigmatism and other distortions that cannot be corrected during production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

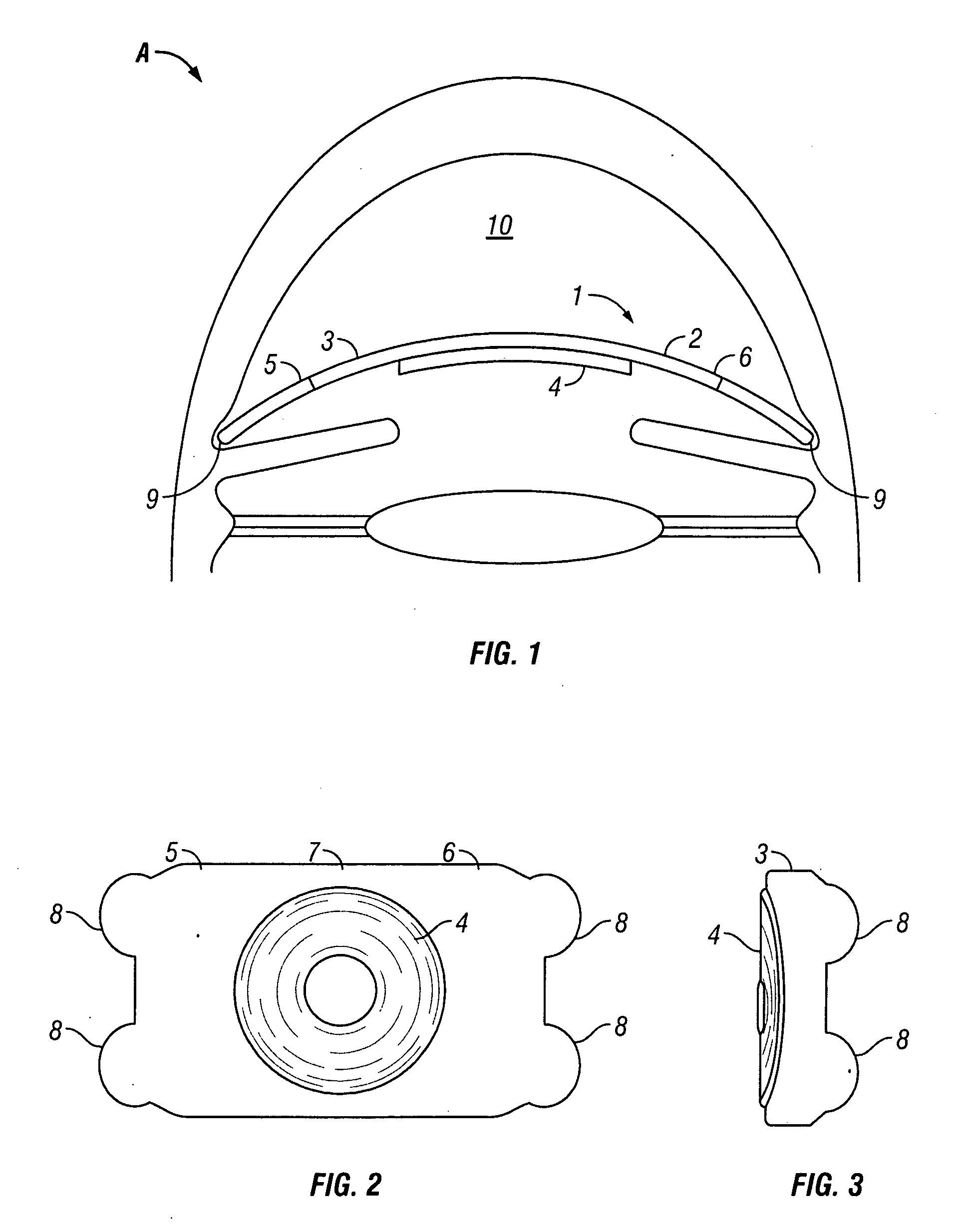

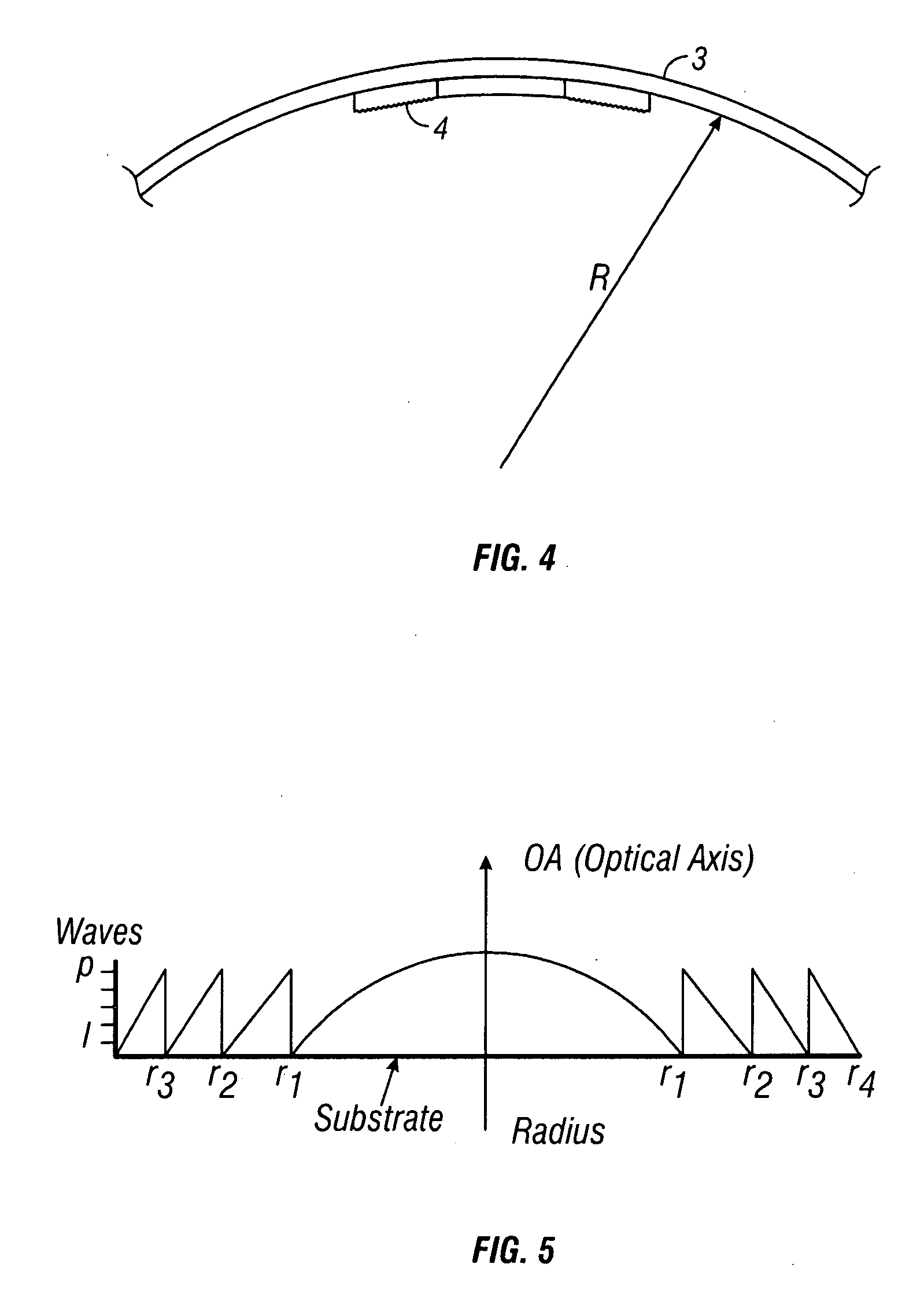

[0024]A thin, foldable, MOD diffractive, polychromatic, intra-ocular implant according to the invention with the following parameters exhibits the following characteristics:[0025]Material: NuSil-MED-6820[0026]Thickness: optic layer 45 microns[0027]Thickness of Substitute: 300 microns[0028]Diameter of corrective portion: 0.65 centimeter[0029]Power: −6 diopters[0030]Number of concentric zones: 50

[0031]Radial location and width of each zone:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

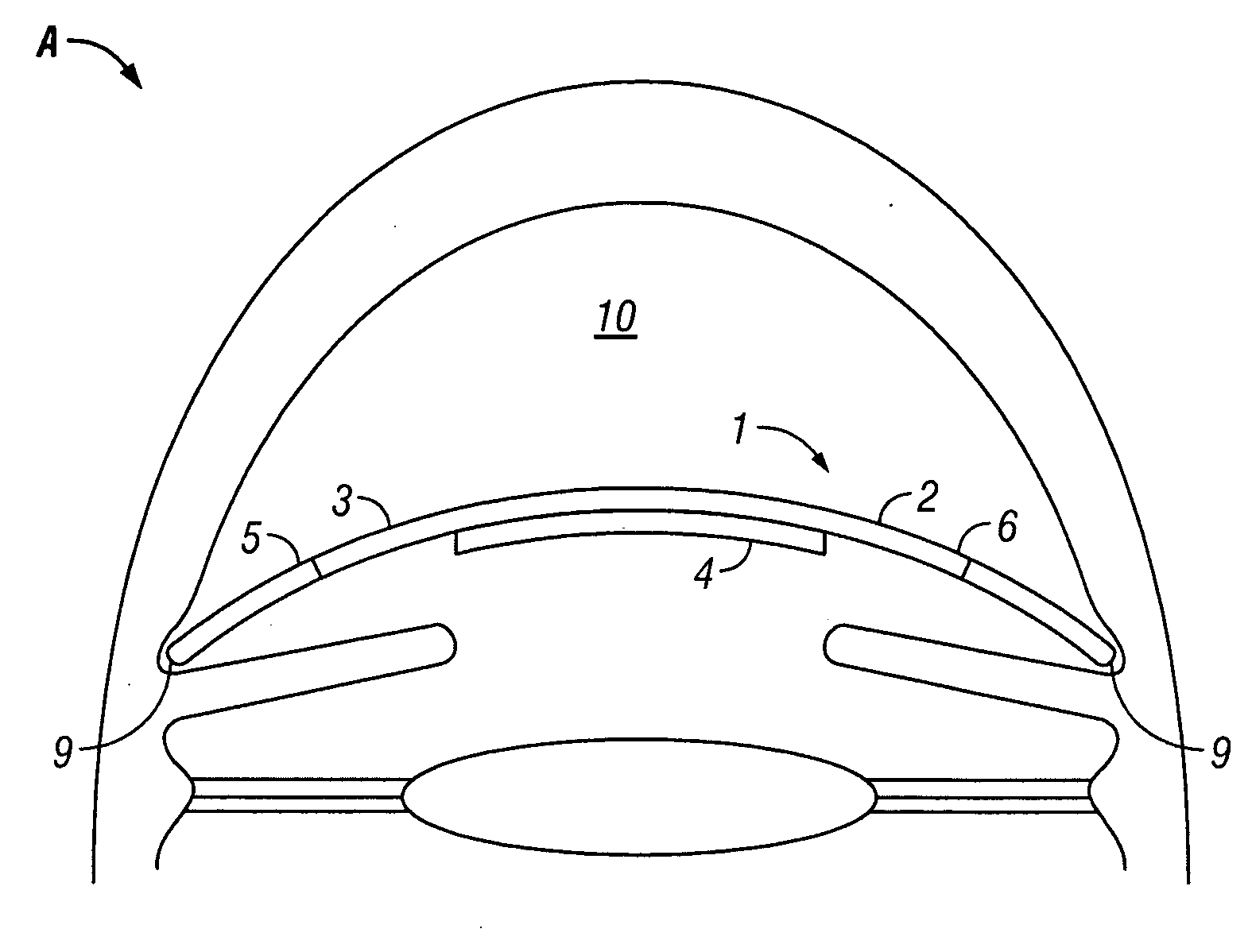

A thin foldable intraocular implant specifically configured for installation into the anterior chamber of a phakic or pseudophakic eye has broad positioning flaps that do not apply any substantial pressure against the wall of the eye. It can be rolled for insertion through a corneal incision as small as 2.75 millimeters. The implant is constituted by a two-layered resiliently flexible membrane having a corrective layer of about 50 to 130 microns and an overall thickness of about 150 to 530 microns, that vaults the iris without contacting it. The optic is constituted by a multi-order diffractive (MOD) structure, and is made of silicone, PMMA, hydrogel or hydrophobic acrylate.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Owner NORDAN LEE T

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com