Product Dispenser Assembly

a product dispenser and assembly technology, applied in the field of retail product holding and feeding mechanism, can solve the problems of reducing potential sales, reducing stocking complexity and time involved in stocking process, and reducing handling time, labor and hence costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

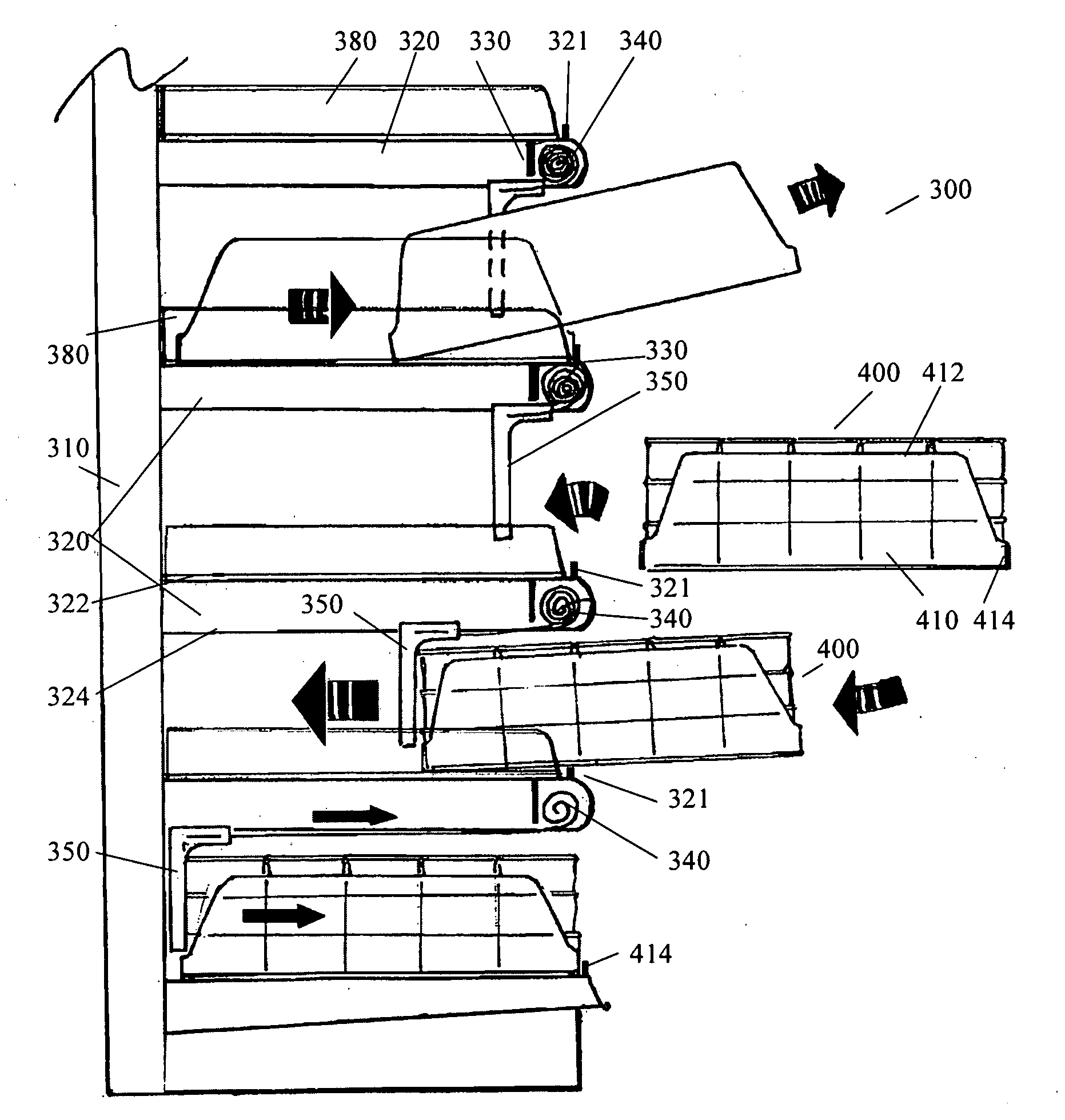

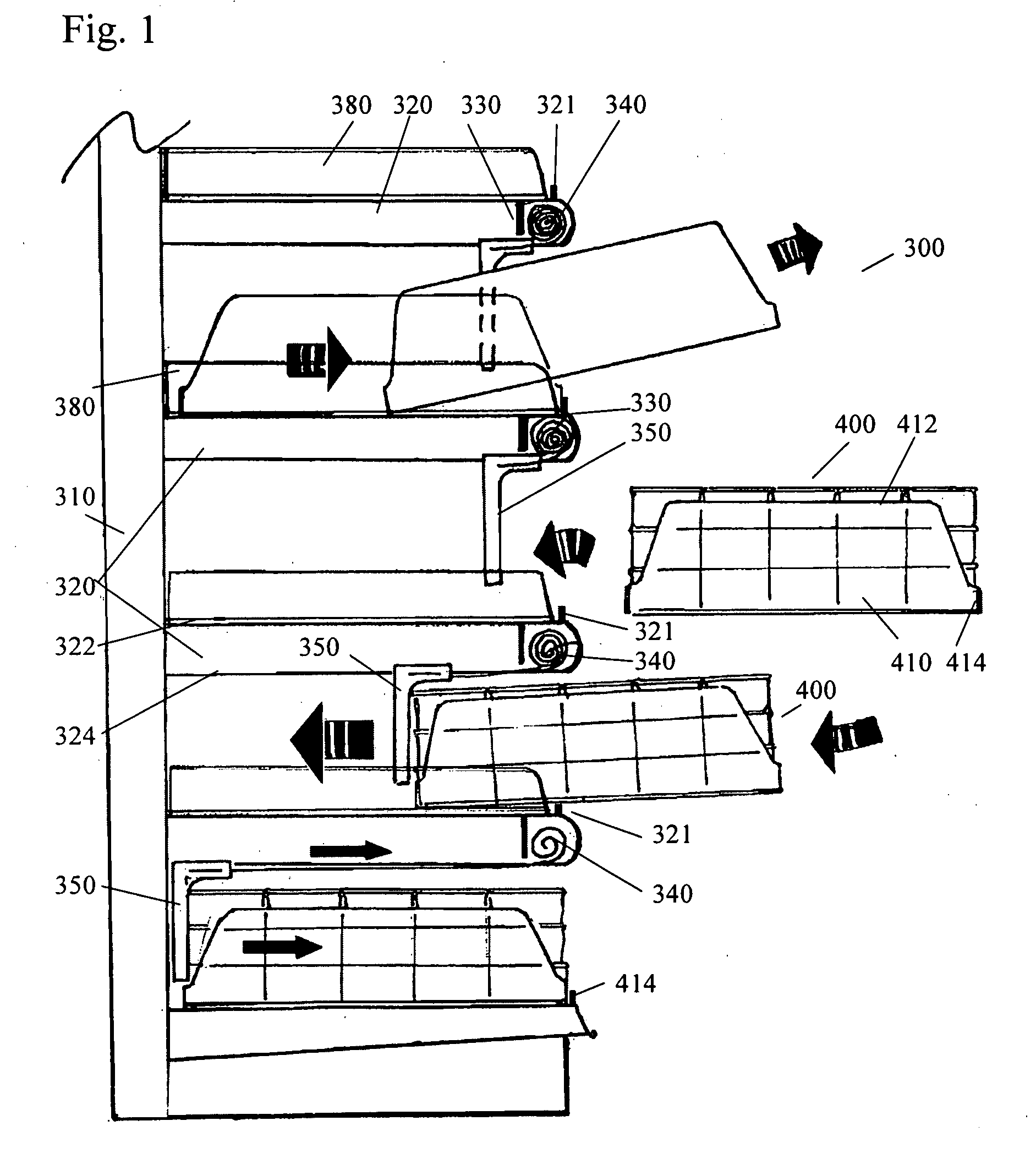

[0034]FIG. 1 shows a dispenser 300 according to the invention, in which the invention is incorporated into a store gondola or fixture 310. This may be a pre-existing fixture which currently holds the pre-existing, ordinary store shelving, or might be specially supplied for the invention. If the pre-existing fixture is used, the ordinary shelves would be replaced with the support platforms 320 of this invention. The support surface 320 can be a planar platform that includes a top surface 322 and an opposing bottom surface 324. The platform 320 is constructed so that a biased product feed mechanism 330 is disposed therein and is configured to controllably advance the product as it is removed by consumers.

[0035]The system of the invention may be used on level shelving, as shown in FIG. 1. However, it will be understood that the feed mechanism 330 of the invention also allows the invention to be used in other arrangements, as shown in FIGS. 11a-11d. Specifically, the invention can be us...

second embodiment

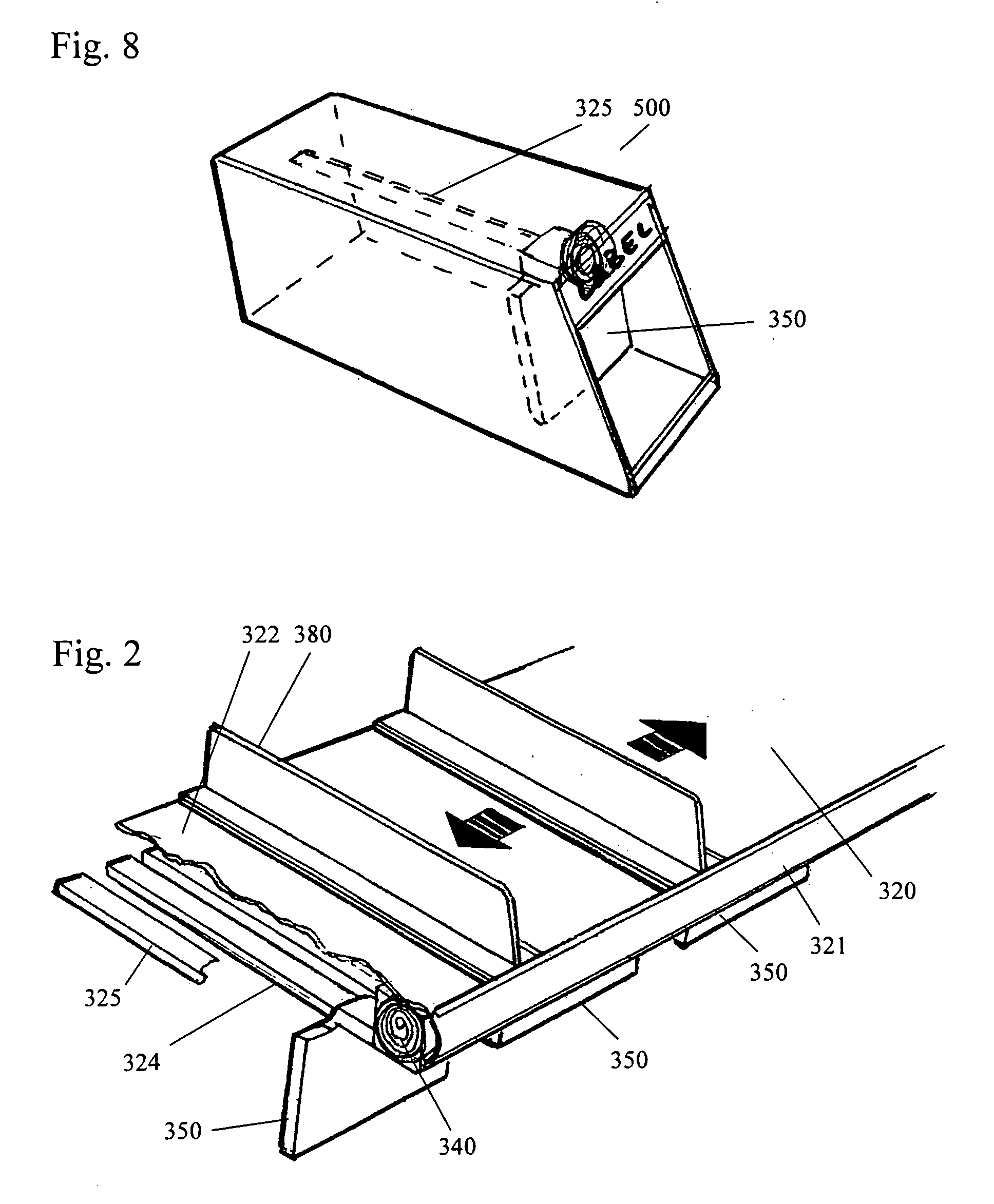

[0068]The system will also work with a second embodiment, shown in FIGS. 8 and 9a-9b, wherein the trays 410 are inserted into and enclosed within individually, size-dedicated stand-alone modules 500. Such a system can be simply and easily installed upon the top surface of any existing store gondola shelving.

[0069]FIGS. 8 and 9b show a perspective view of a single enclosed housing module 500 with a single feed mechanism. A single spring-biased pusher plate 350 is disposed within the housing 500 and advances the product 50 forward into the open area 540 from which a consumer may select the product. The tray is held within the enclosure by stop wall 541, which serves the same function as the stop wall 321 in the shelf embodiment. Similarly, the side walls of the enclosure serve the same function as the row dividers 380 of the shelf embodiment. As with the previous embodiment, the pusher plate 350 is disposed extending downward from track 325 and is spring-biased to the front of the mod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap