Multi-mount

a multi-mount and mount technology, applied in the field of multi-mount, can solve the problems of increasing the weight of the firearm, limited space on the 1913 rail, and inability to carry a firearm at night time, so as to facilitate removable securing, save weight, and add weight to the firearm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

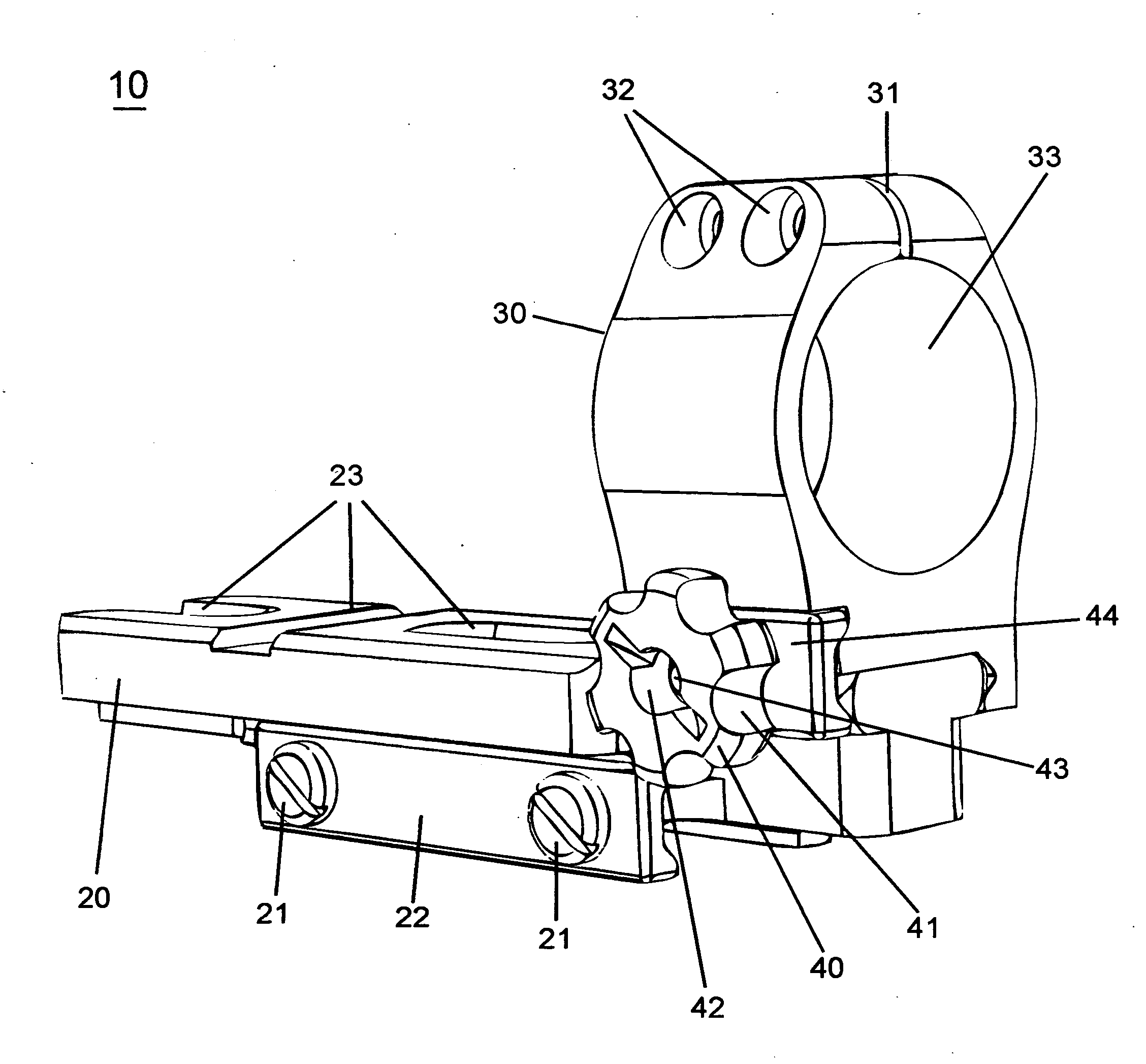

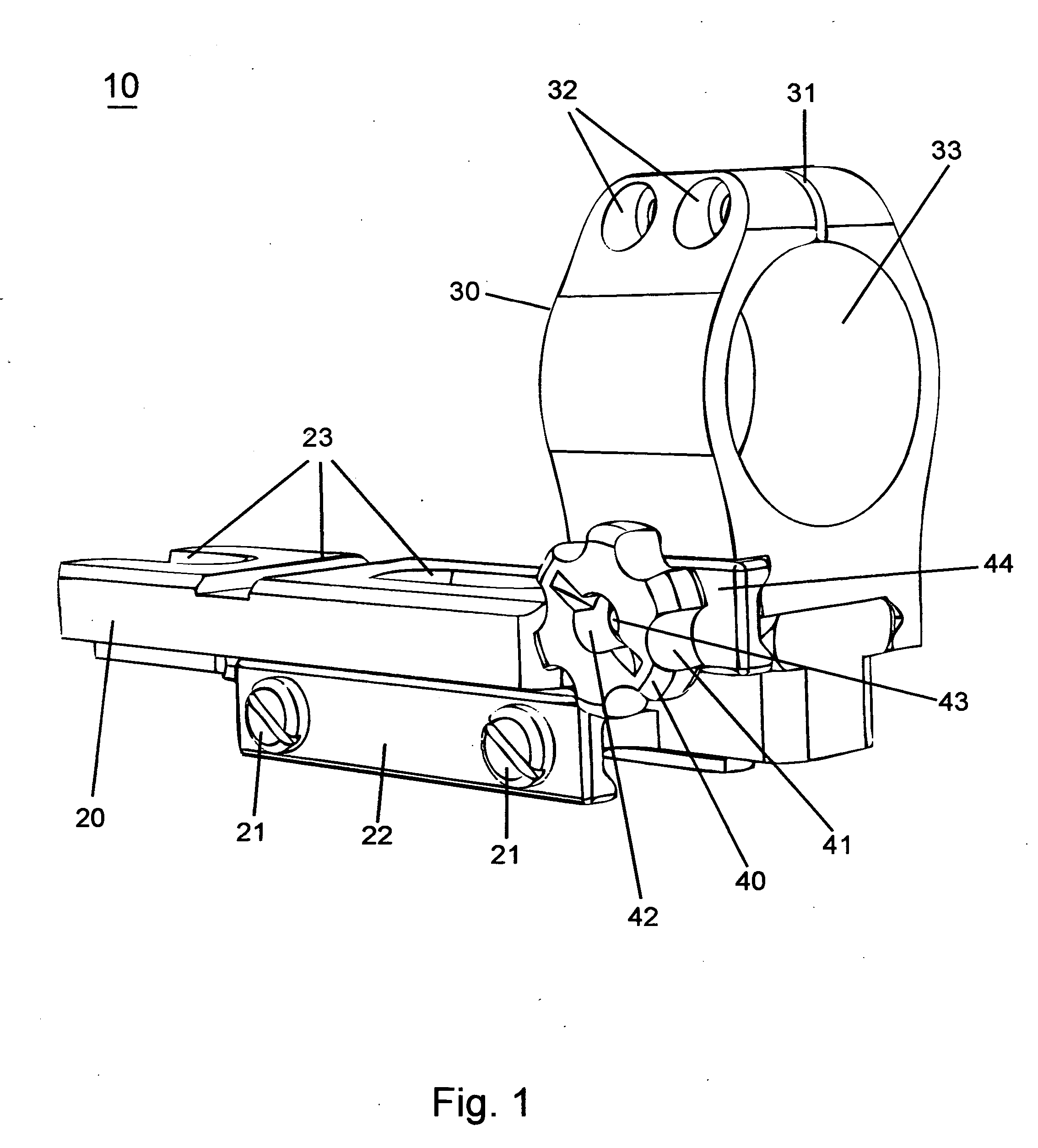

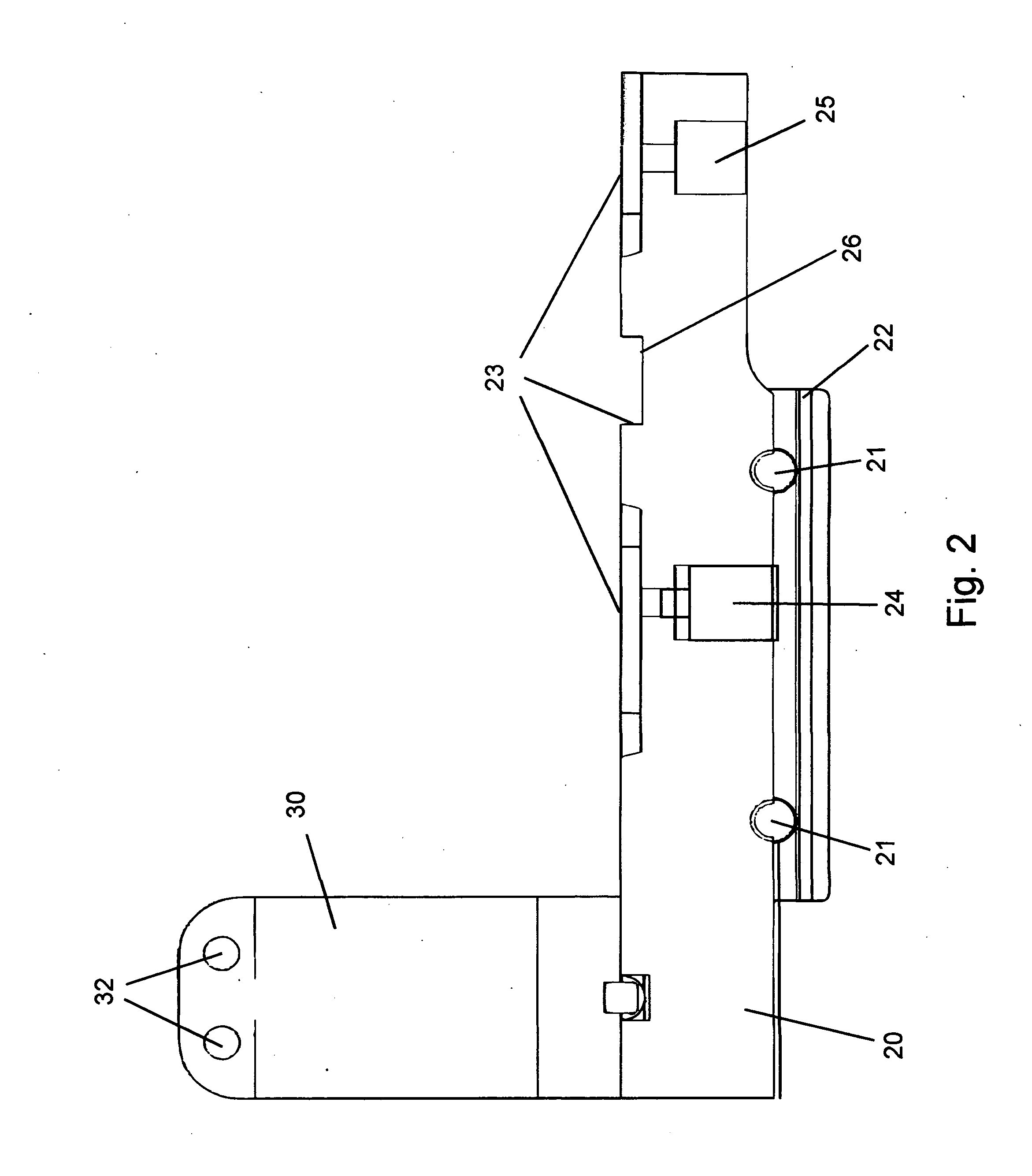

[0023]Referring to the drawings in detail wherein like elements are indicated by like numerals, there is shown in FIG. 1, perspective side view of the proposed multi mount 10. The main components are the base 20, and the secondary optic ring 30. The base 20 is design to interface with a 1913 spec Picatinny rail, well known in the prior art. There are two screws 21, and a retaining plate 22 which hold the base 20 onto a Picatinny rail.

[0024]The secondary optic ring 30 is retained onto the base 20 by means of a retention knob 40 which places pressure on a retention plate 44, when the retention knob 40 is threadedly secured to a screw 43 which runs transverse to the axis of the base 20.

[0025]The secondary optic ring 30 has a gap machined into the top portion of the ring 30. Two retention screws 32 are threaded into the aluminum housing and when tightened to close the gap 31 on the secondary optic ring 30. A 30 mm void 33 for an optic is provided on the secondary optic ring 30. The appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com