Personal Care and Dermatologic Compositions

a technology of compositions and personal care, applied in the field of personal care and dermatologic compositions, can solve the problems of skin or hair drying, synthetic organic polymers often crack on dynamic surfaces, and polymers with limitations in plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

[0097]The following examples are further illustrative of the present invention. The components and specific ingredients are presented as being typical, and various modifications can be derived in view of the foregoing disclosure within the scope of the invention.

Raw Material Example

Terminal Disilanic-Hydrogen Silicone Polymers

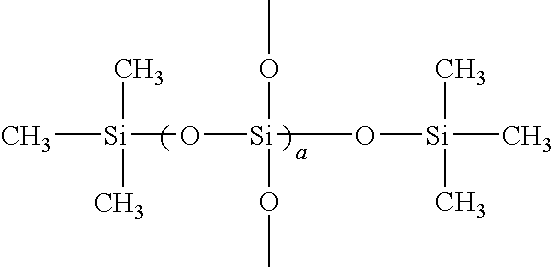

[0098]Terminal disilanic-hydrogen silicone polymers are commercially-available from Siltech Corp. (Toronto, Canada). They conform to the following structure

[0099]wherein x is an integer ranging from 0 to 5000.

Examplex10220350475510061257200850091000102000

Raw Material Example

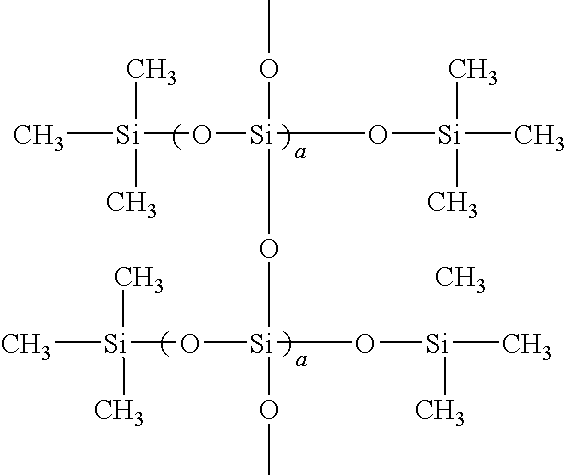

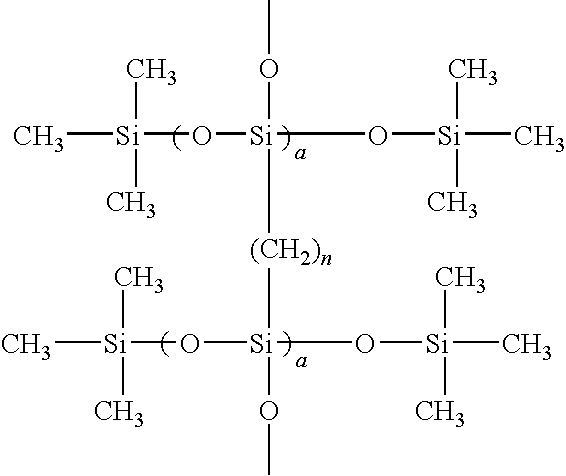

Terminal Divinyl Silicone Polymers

[0100]Terminal divinyl silicone polymers are commercially-available from Siltech Corp. (Toronto, Canada). They conform to the following structure:

[0101]wherein y is an integer ranging from 0 to 2000.

Exampley11200012100013500142001512516100177518501920200

Raw Material Example

Hydrosilylation Solvent

[0102]The hydrosilylation reactions are advantageously run in a...

example gg

Eyeliner (Example GG)

[0140]

INCI Name%Isododecane7.00Nylon 611 / dimethicone copolymer / 19.60PPG-3 myristyl ether Polysilicone-65.00Blue 1 lake25.00Red 40 lake4.00Yellow 5 lake3.60Green 50.80Silica0.05Isododecane / quaternium-18 hectorite7.00Propylene carbonate Dibutyl adipate25.80Methylparaben2.95Dehydroacetic acid0.35Propyl paraben0.20Sorbic acid0.10Example 365.56

[0141]Makeup Remover (Example HH)

INCI Name%Butylene glycol dicaprylate / dicaprate8.00Example 2510.00Phenoxyethanol5.00Propylparaben1.00Isododecane / quaternium-18 hectorite / 0.10Propylene carbonate Cetyl dimethicone copolyol20.00Cyclomethicone2.50Butylene glycol5.00Trisodium EDTA0.01Methylparaben0.25Waterqs100

[0142]The above-described composition is prepared as follows: Separately combine the oil phase ingredients and the water phase ingredients. Then, mix well to emulsify.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com