Arcuate magazine for a firearm and a method for making the same

a technology for firearms and magazines, applied in the field of cartridge magazines for firearms, can solve the problems of ineffective or dangerous use of weapons in the field, inability to use magazines, and failure of keyways to form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

(I) The Magazine

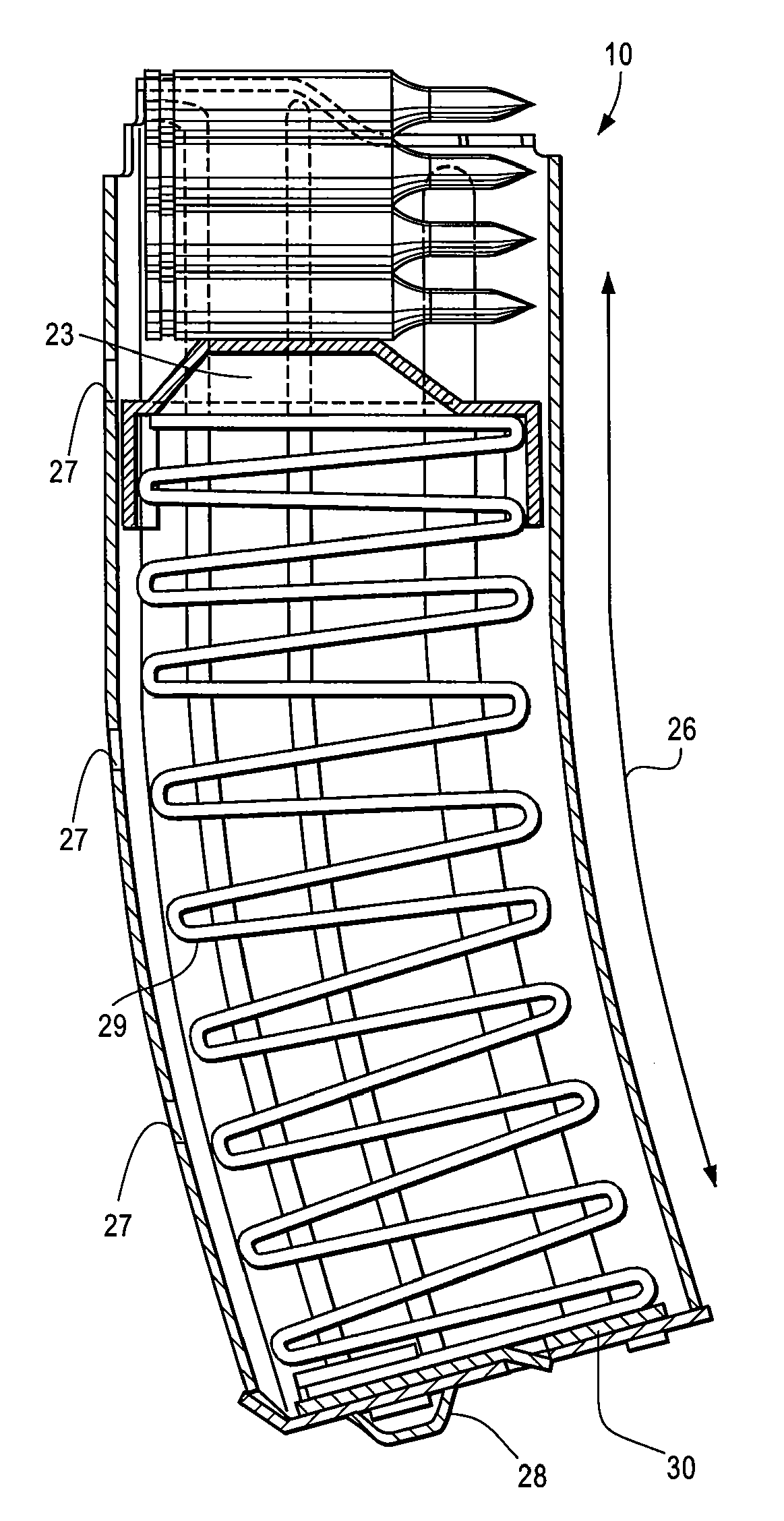

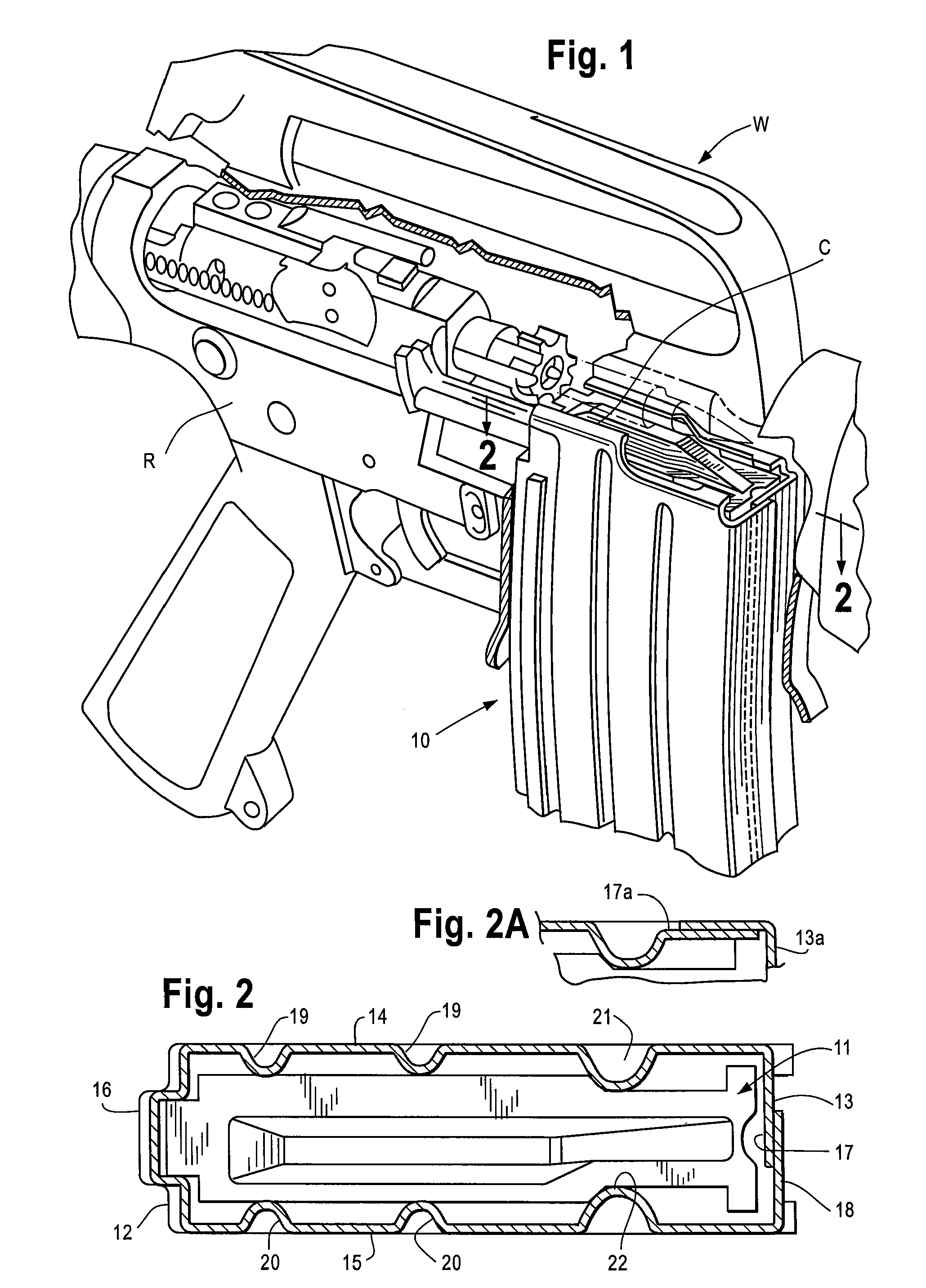

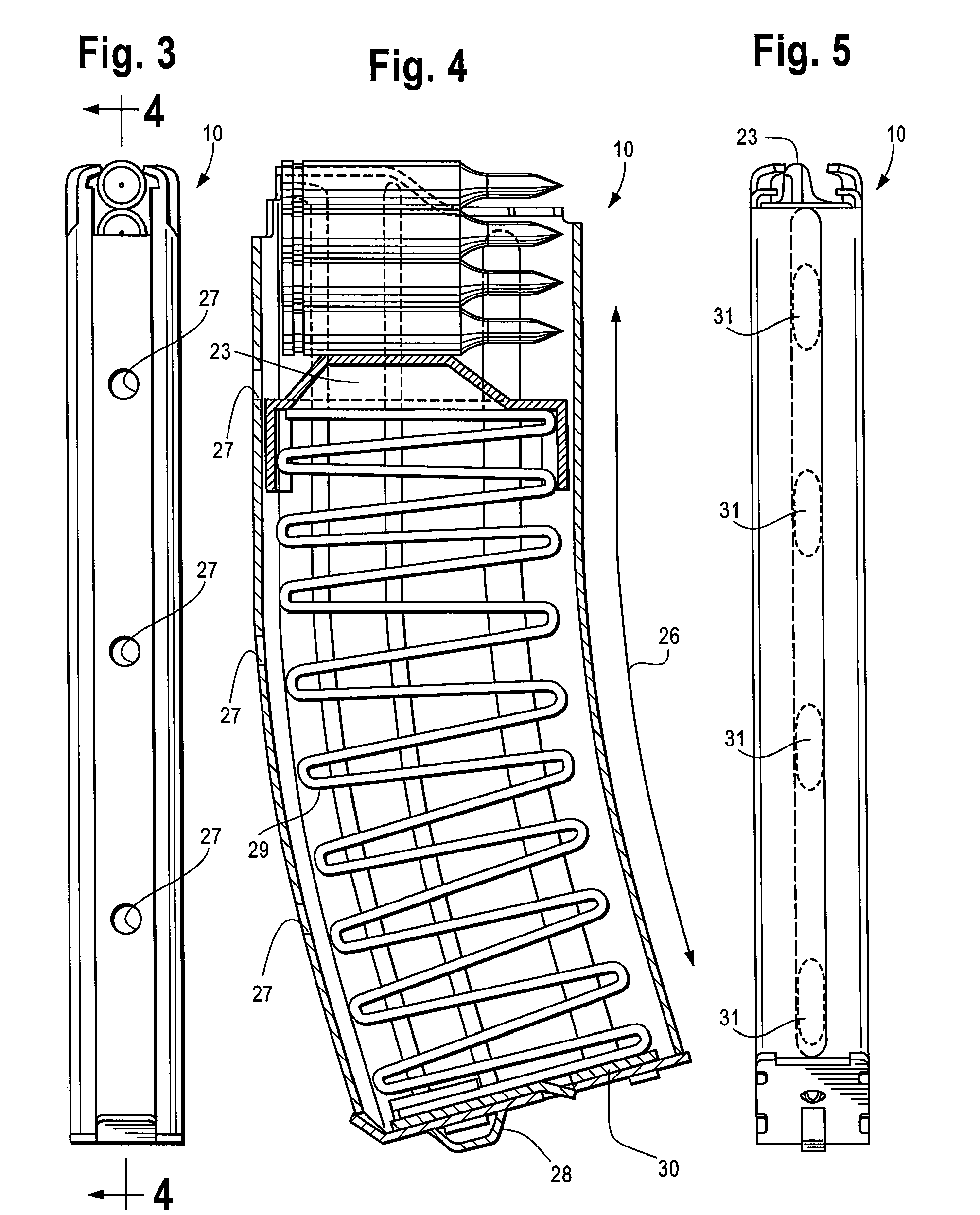

[0046]With reference to FIGS. 1-5, a magazine 10 embodying the present invention is installed in a rifle or carbine weapon W, in position for a round of ammunition to enter the firing area C of the weapon. The ammunition is delivered to the firing area C by means of a spring loaded follower 11 which travels through the magazine 10 as each round is placed in firing position.

[0047]The magazine 10 is secured in the weapon W in a receiver R and the magazine comprises spaced apart short walls 12 and 13, bridged by space apart long walls 14 and 15. One of the short walls 12 has arranged therein a keyway 16, and the other short wall 13 comprised of edge sections 17 and 18 which overlap one another and are secured by welds. A plurality of ribs 19 and 20 are arranged opposed and in line with one another in the long walls 14 and 15, and on set of aligned ribs 21 and 22 may be larger and deeper than the other sets of ribs. Within the interior of the walls 12-15, the follower 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com