Flexible support apparatus

a support device and flexible technology, applied in the direction of mechanical devices, machine supports, other domestic objects, etc., can solve the problems of not being particularly portable, careful removal and disassembly, and wall damage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

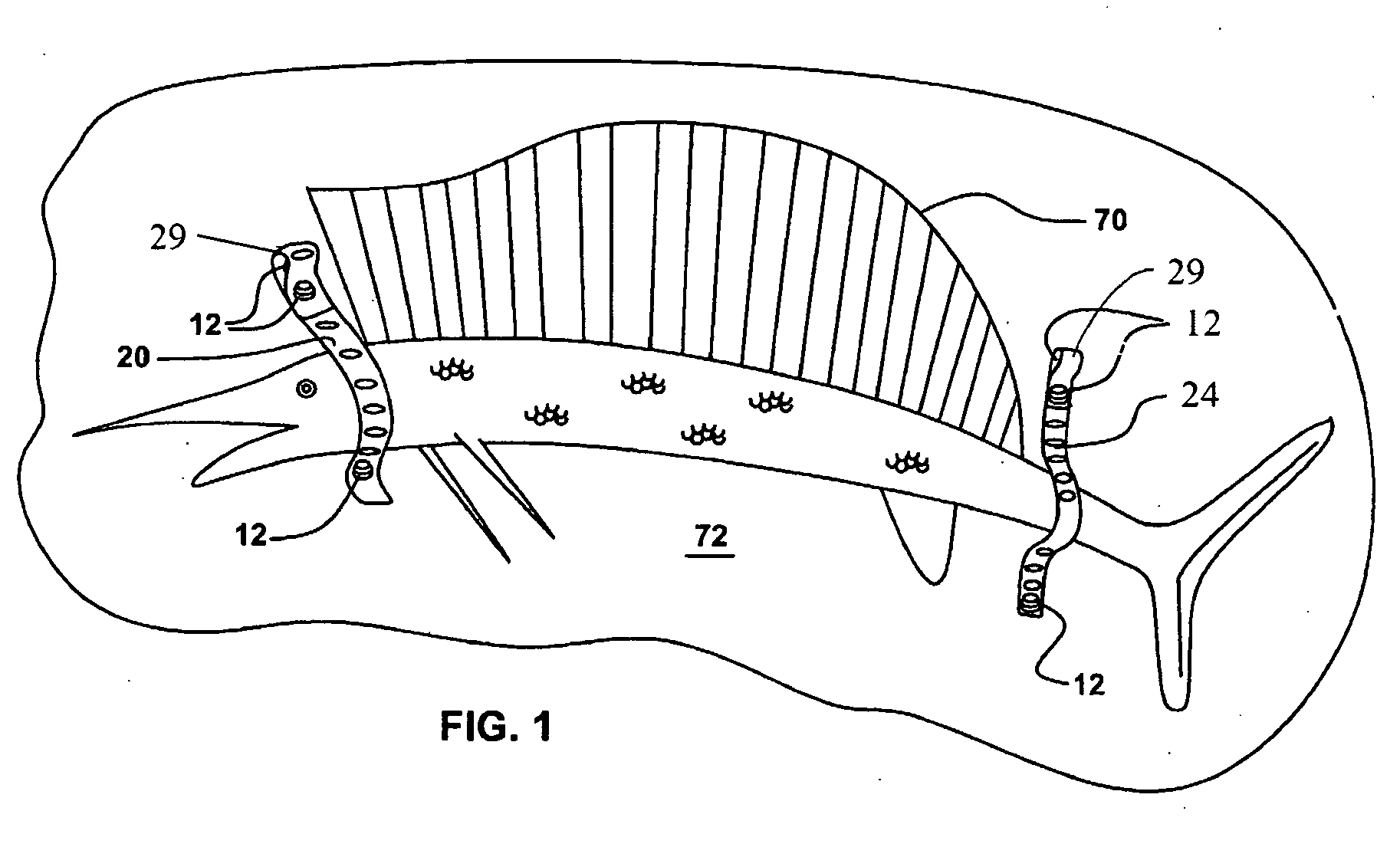

first embodiment

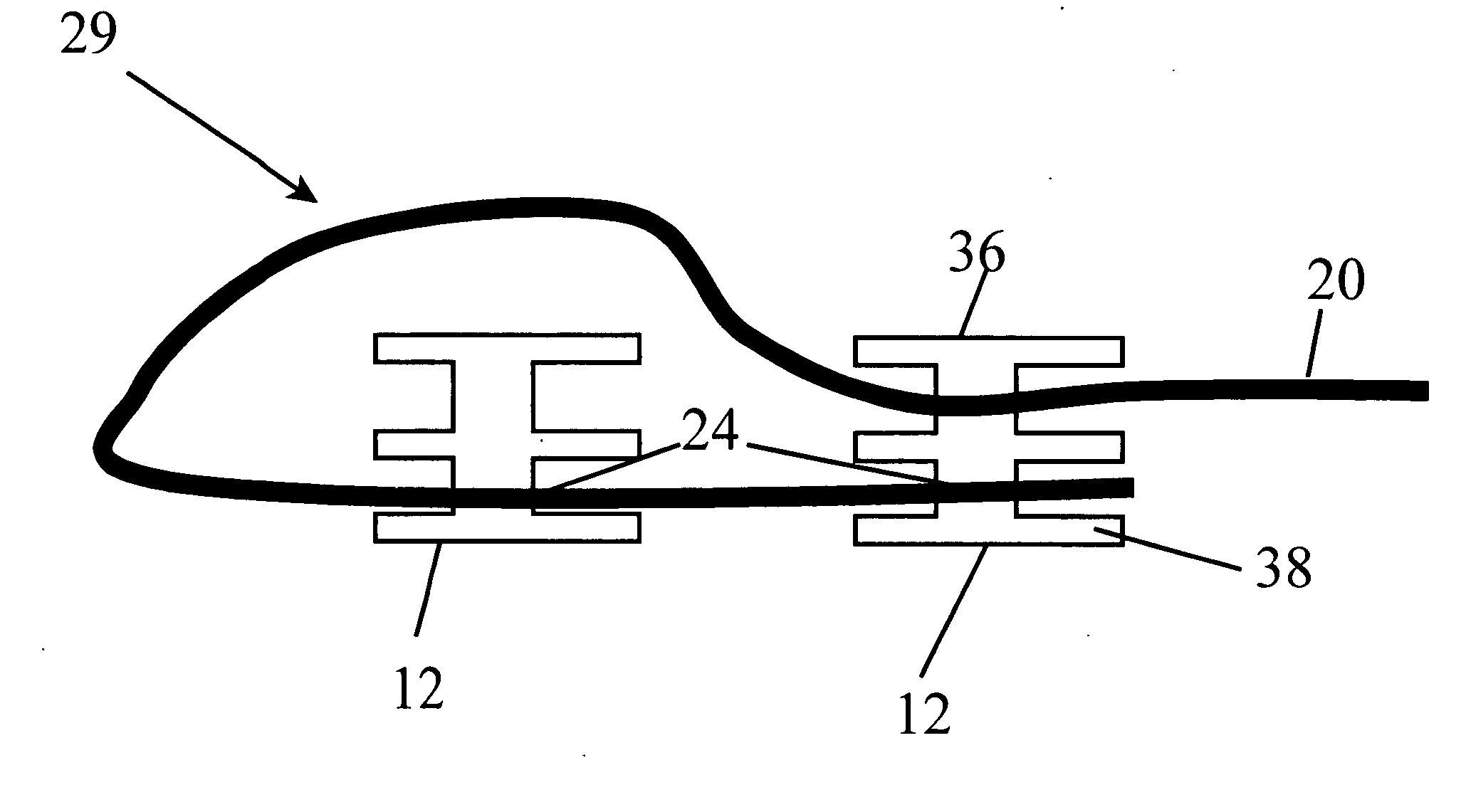

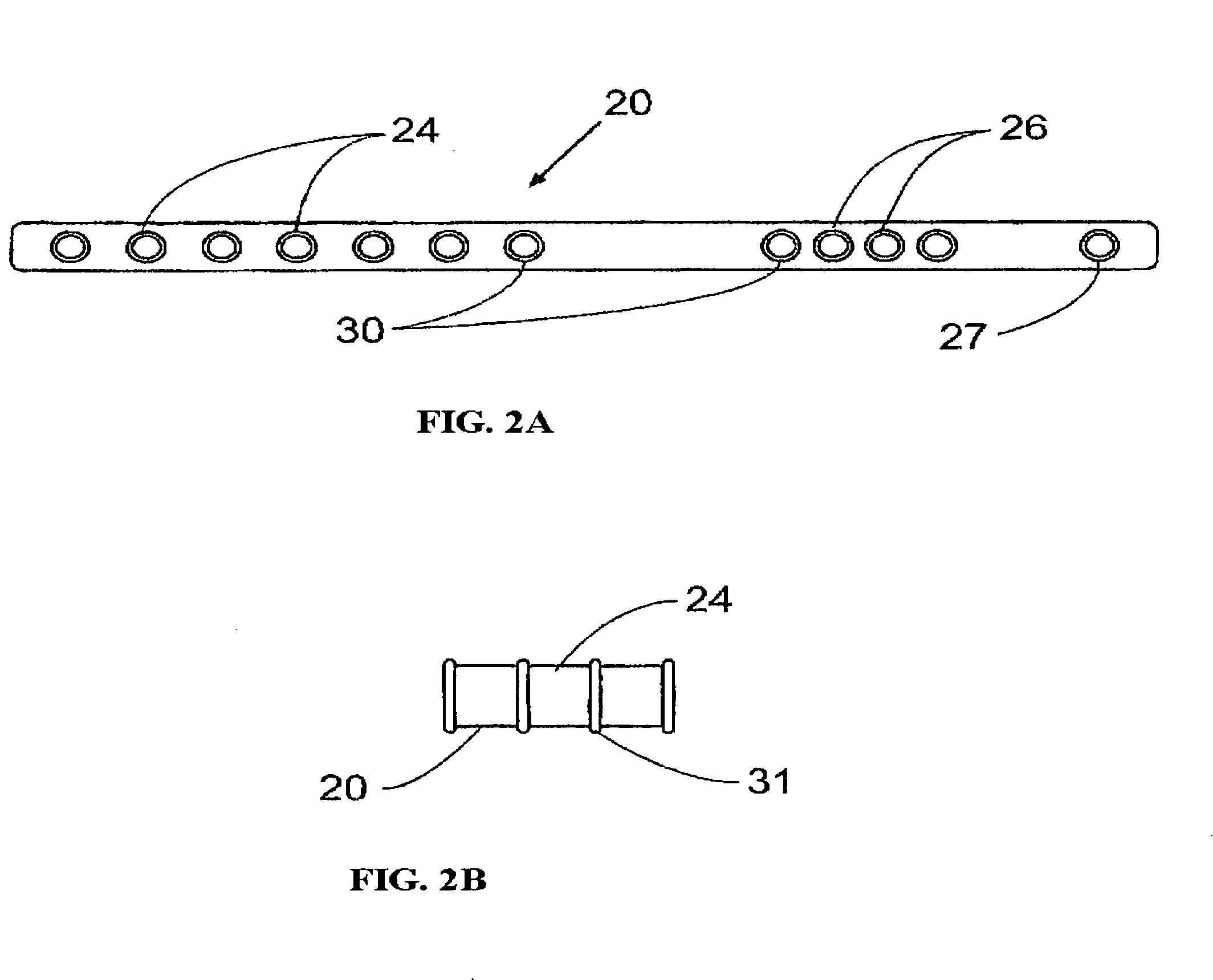

[0027]The anchoring member 12, as shown in FIG. 3A, includes an outer sleeve or portion 31 which is formed of a central post 34 with an axial bore 35 that connects opposing end discs 36, 38 as well as central disc 40, and an inner portion 42 which is a fastener such as a screw or nail. In a first embodiment, end disc 38 and central disc 40 have the same diameter, but end disc 36 has a diameter approximately 25% smaller than discs 38 and 40. The size and number of discs can vary according to function as discussed in more detail below. Also, the discs 36, 38, 40 may be slightly elliptical or any other gem An integral construction may be used to form the outer portion 31 of anchoring member 12, the outer portion 31 preferably being formed of unitary construction, e.g., by molding. Any rigid, durable material may be used to form the anchoring member 12 such as a hardened plastic. The axial bore 35 extends through the anchoring member 12, the bore sized to receive a fastener 42 such as a...

fourth embodiment

[0031]Also as mentioned above, an anchoring member 112 with only two discs, 138, 140 may be used as shown in FIG. 3C. This embodiment of the anchoring member 112 is expedient when used as a non or limited weight bearing attachment and allows for quick release of the apparatus. Such an anchoring member may be used for example in the place of lowermost anchoring member 112 as shown in FIG. 1. Discs can be all large diameter to increase resistance to accidental disengagement when heavy objects are supported or movement of the supported article is anticipated. An all large diameter disk anchoring member 212 is shown in cross section in FIG. 3B. Member 212 includes an outer sleeve or portion 231 which is formed of a central post 234 with an axial bore 235 that connects opposing end discs 236, 238 as well as central disc 240, and an inner portion 242 which is a fastener such as a screw or nail. the anchoring member 312 is shown in FIG. 3D, and can be seen to have three discs 336, 338, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com