Oil Pan

a technology of oil pans and oil cylinders, applied in the direction of auxilary lubrication, machines/engines, mechanical equipment, etc., can solve the problems of increasing cost and complexity, increasing the service life of engines, and increasing the chance of leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

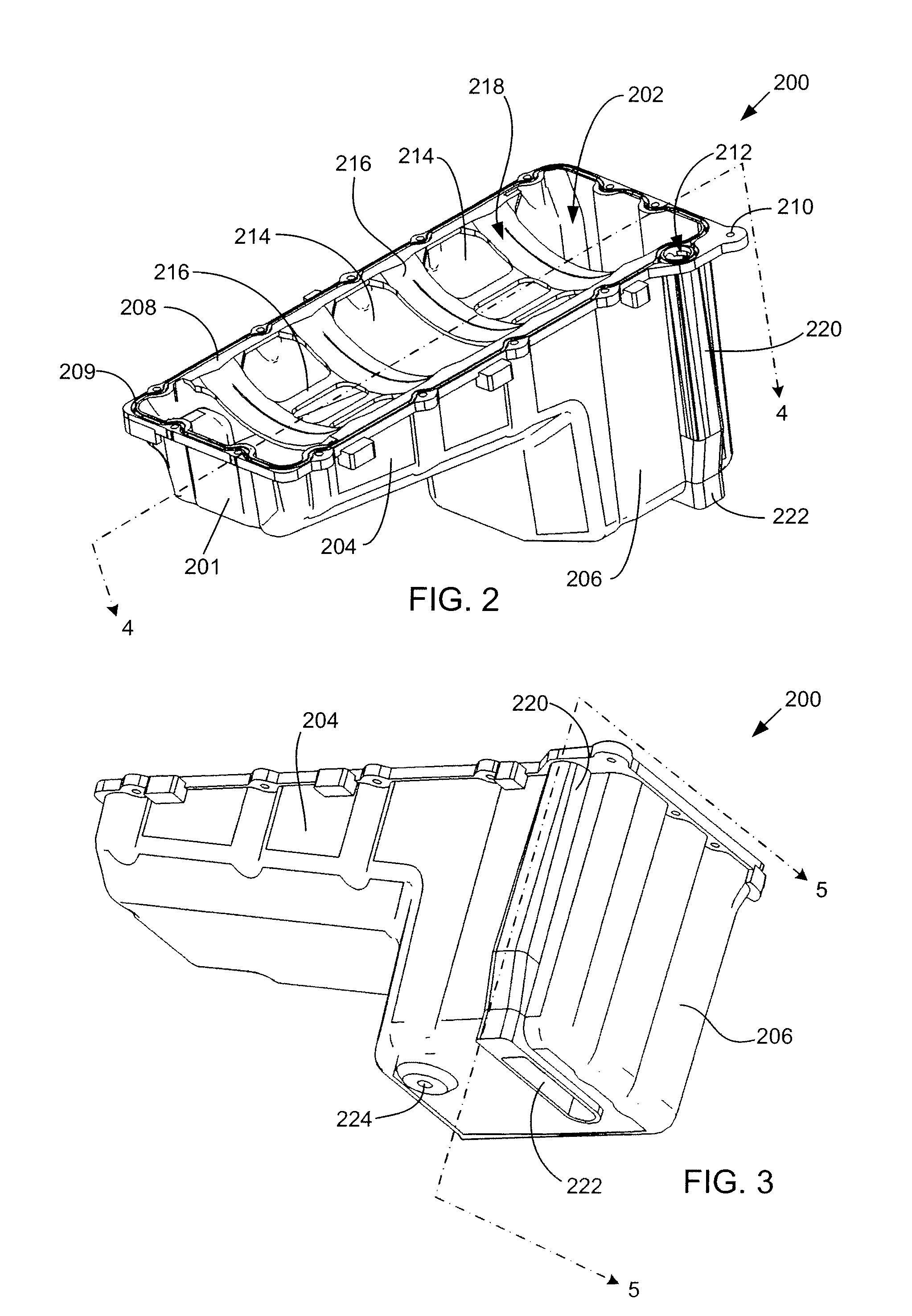

[0013]The following describes an integrated oil pan for an internal combustion engine.

[0014]In one embodiment, the integrated oil pan is a single piece that incorporates the functions of a lower oil pan, an upper oil pan, and an oil pick-up or suction tube. The integrated oil pan may have superior resistance to leakage and failure, be less costly and easier to install when compared to traditional oil pan assemblies.

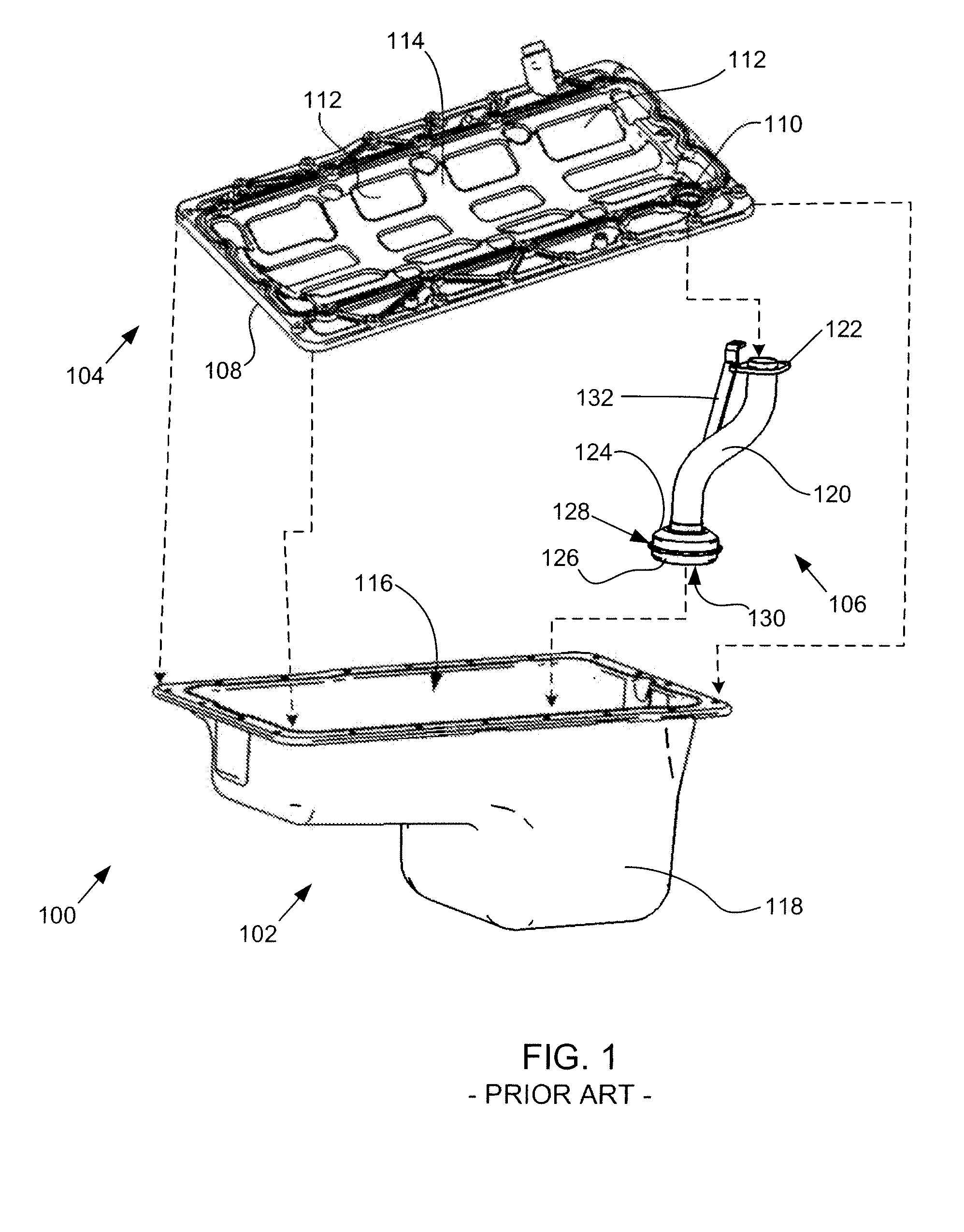

[0015]A prior art oil pan assembly 100 is shown in exploded view in FIG. 1. The oil pan assembly 100 includes a lower oil pan 102, an upper oil pan 104, and a pick-up tube 106. When the oil pan assembly 100 is assembled as shown in FIG. 1, the upper pan 104 is connected to the lower pan 102 along a peripheral sealing surface 108. The pick-up tube 106 is connected to the upper pan 108 at a pass-through opening 110 that is sealed to allow oil that is drawn from the lower pan 102 by the pick-up tube 106 to enter the engine (not shown).

[0016]The upper pan 104 advantageously i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com