Method and apparatus for optimal nock travel for a compound archery bow

a compound bow and nock travel technology, applied in the field of compound bows, can solve the problems of cam(s) tilting, angular lateral displacement of the bow string, deviation from the natural travel path, etc., and achieve the effect of quick reduction of cable offs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0055]Turning next to FIG. 9, there is shown a top view of the cable guard rod of the present invention.

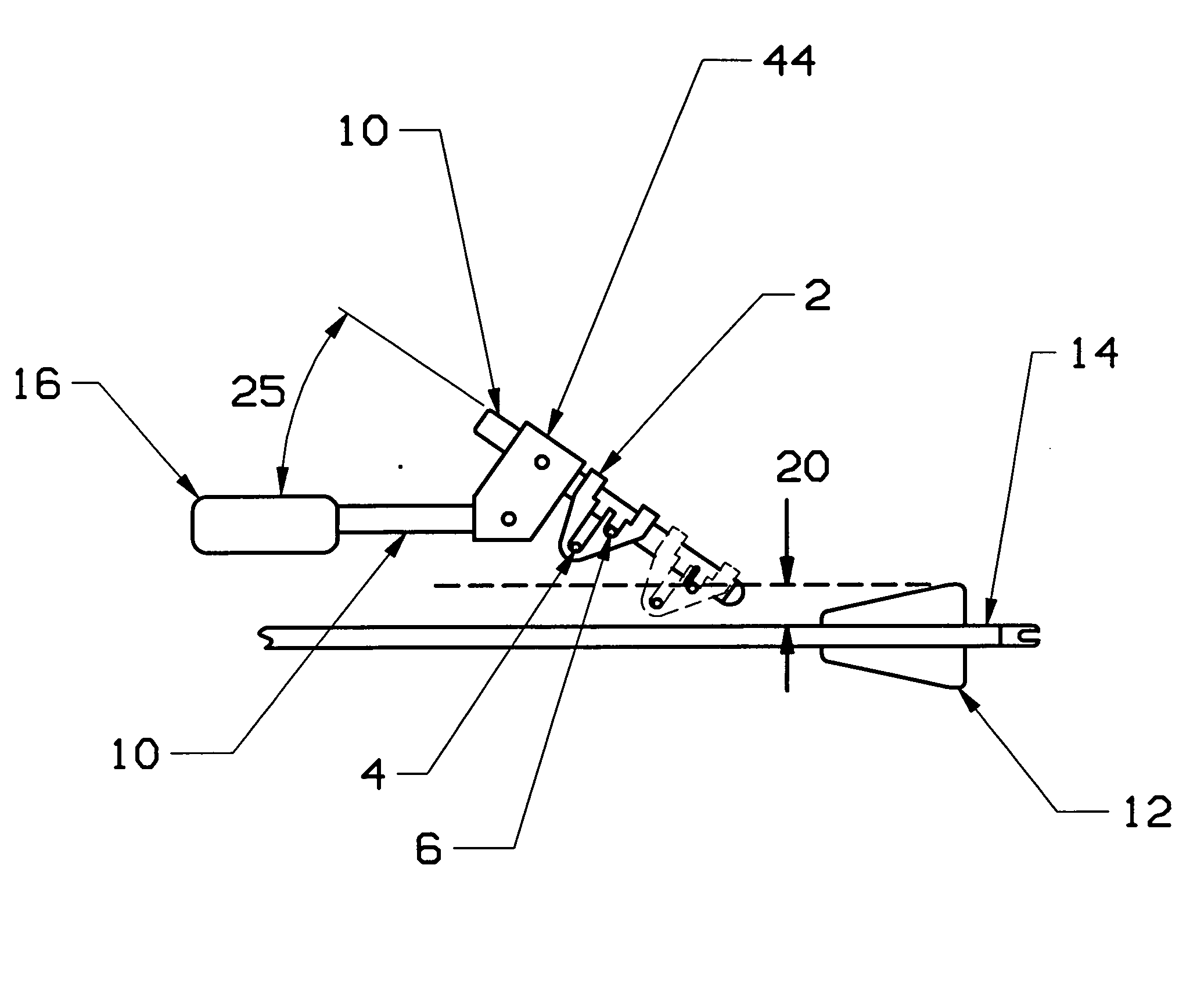

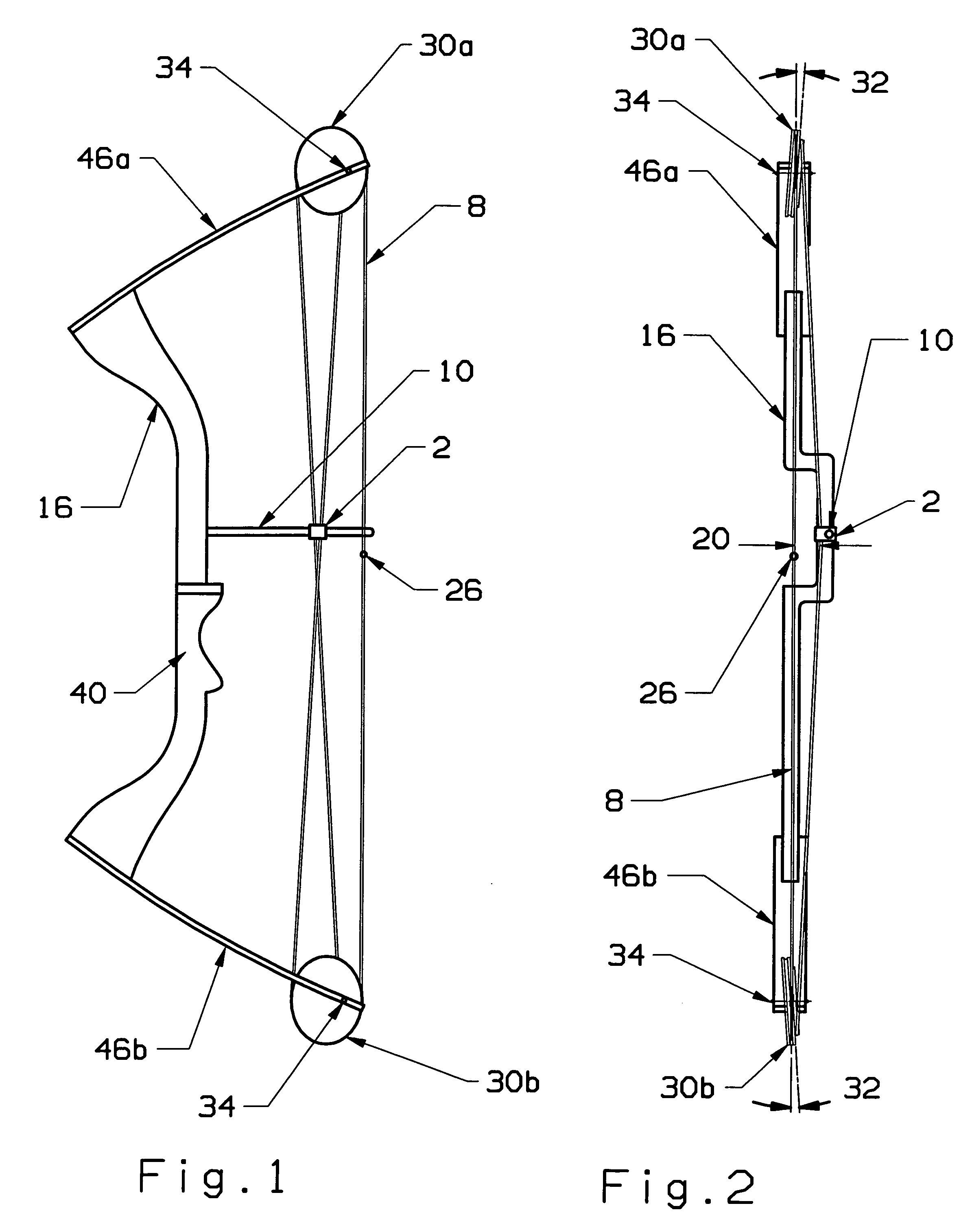

[0056]The cable guard rod 10 is preferably a single piece which is mounted to the bow's riser 16. The cable guard rod 10 can be made of any material suitable to the purpose, though a preferred embodiment would be the use of aluminum or a composite. The bow's cables 4, 6 are located in a cable slide 2 which slides on the cable guard rod 10. The cable slide 2 has a means of locating and trapping the bow's cables to prevent them from contacting each other during normal operation. The cable slide 2 must move laterally approximately 0.6″ towards the arrow 14 within the rearward / forward motion determined by the cable's 4, 6 movement so as to provide clearance 20 for the fletching 12.

[0057]There is created an exterior angle 25 from the upper portion of the cable guard rod 10 to the lower portion of the cable guard rod. The lower portion of the cable guard rod 10 is essentially perpendicu...

third embodiment

[0059]With reference next to FIG. 10, there is shown a top view of the cable guard rod of the present invention.

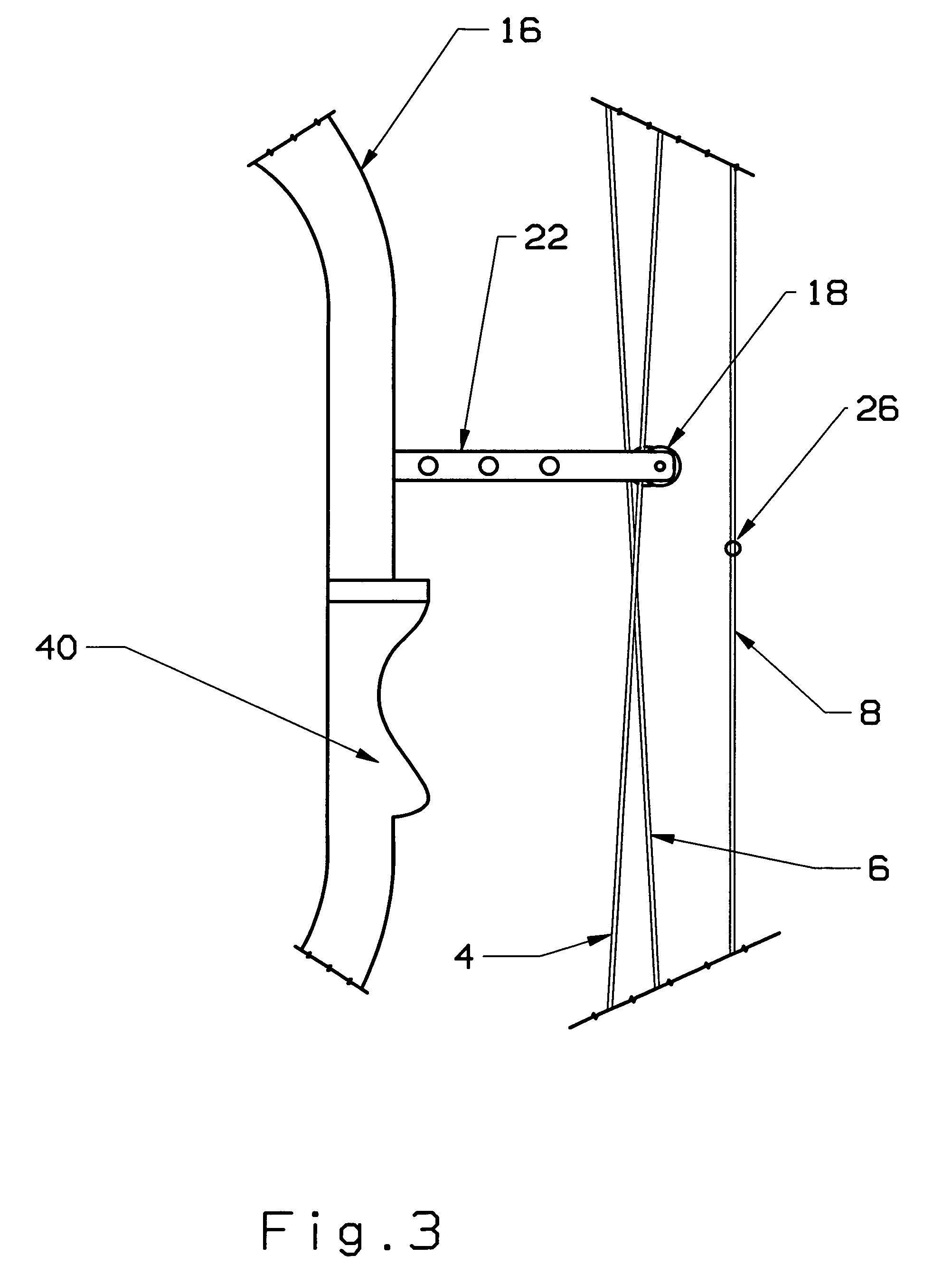

[0060]The cable guard rod 10 / block 44 is mounted, either directly or indirectly, to the bow's riser 16 of the frame. The cable guard rod 10 is comprised of two parts (an upper half and a lower half) and its corresponding block 44. The cable guard rod 10 and bracket 22 can be made of any material suitable to the purpose, though a preferred embodiment would be the use of aluminum or a composite. The bow's cables 4, 6 are located in a cable slide 2 which slides on the cable guard rod 10. The sliding block 2 has a means of locating and trapping the bow's cables to prevent them from contacting each other during normal operation. The cable slide 2 must move laterally approximately 0.6″ towards the arrow 14 within the rearward / forward motion determined by the cable's 4, 6 movement.

[0061]There is created an exterior angle 25 from the upper portion of the cable guard rod 10 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com