Loop-shaped Sling Adapter for use on Buffer Tube Assembly or Rifle Stock

a buffer tube and adapter technology, applied in the field of slings for weapons, can solve problems such as unfavorable handling, and achieve the effects of convenient, flexible, and inexpensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

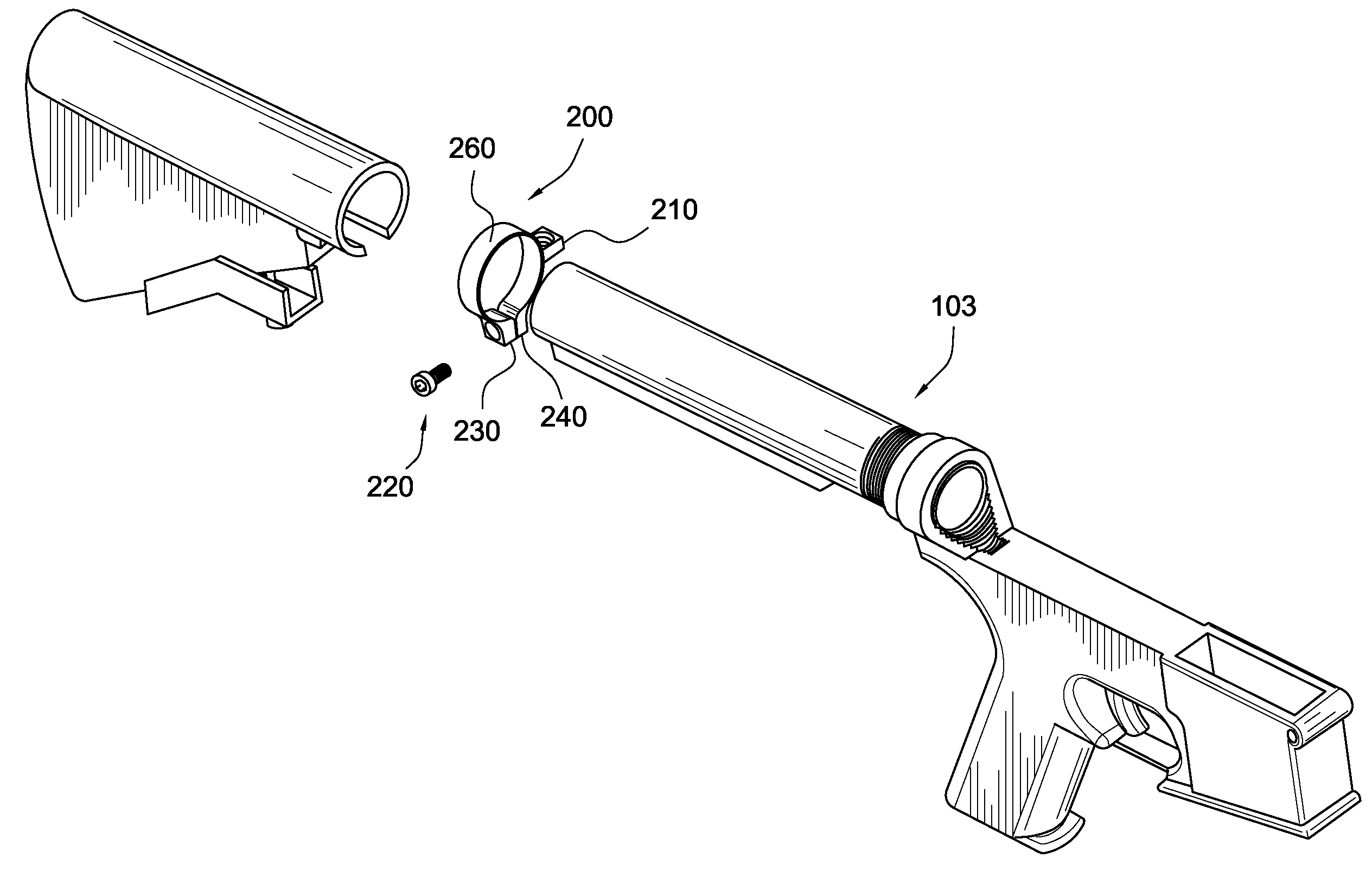

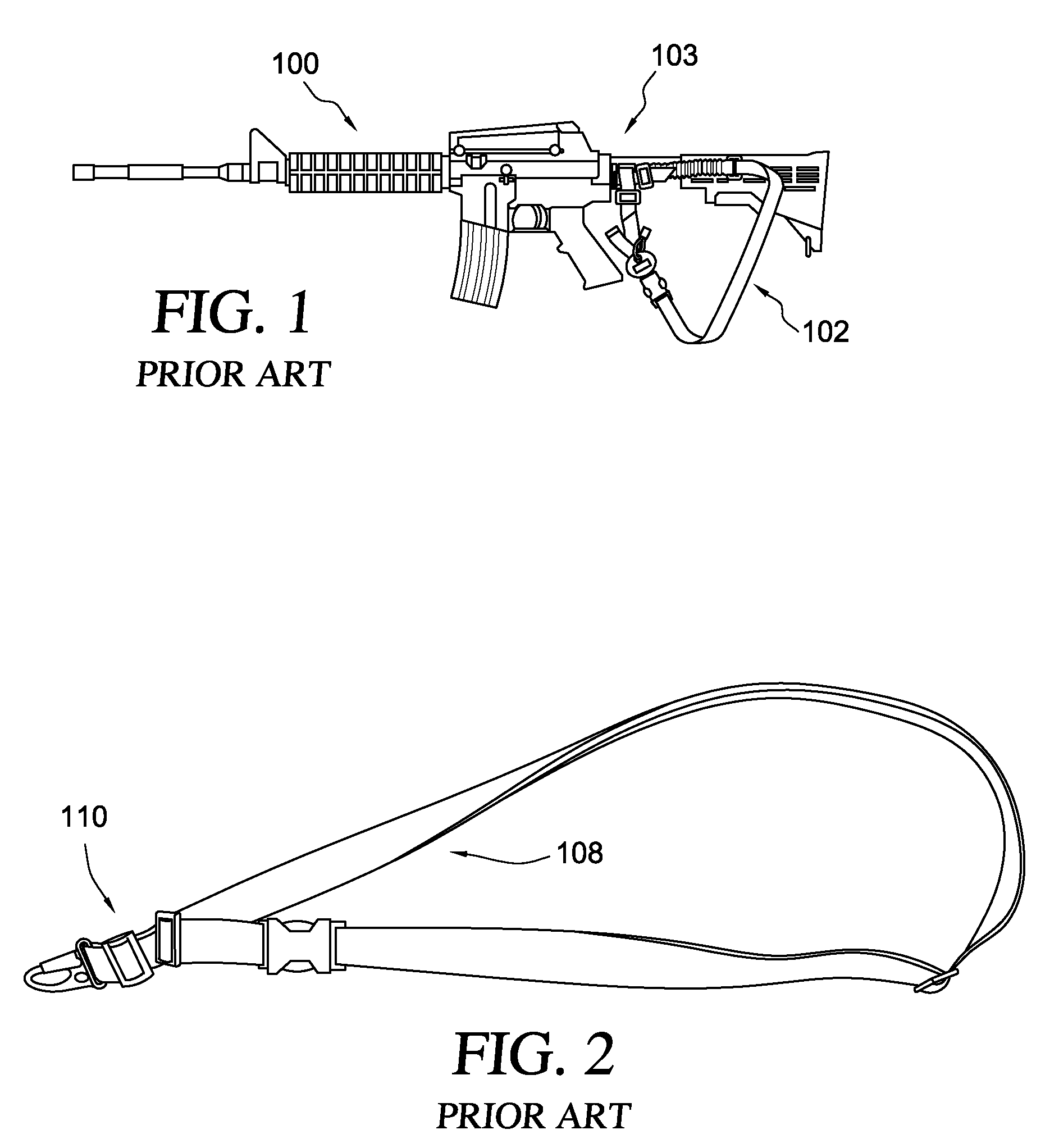

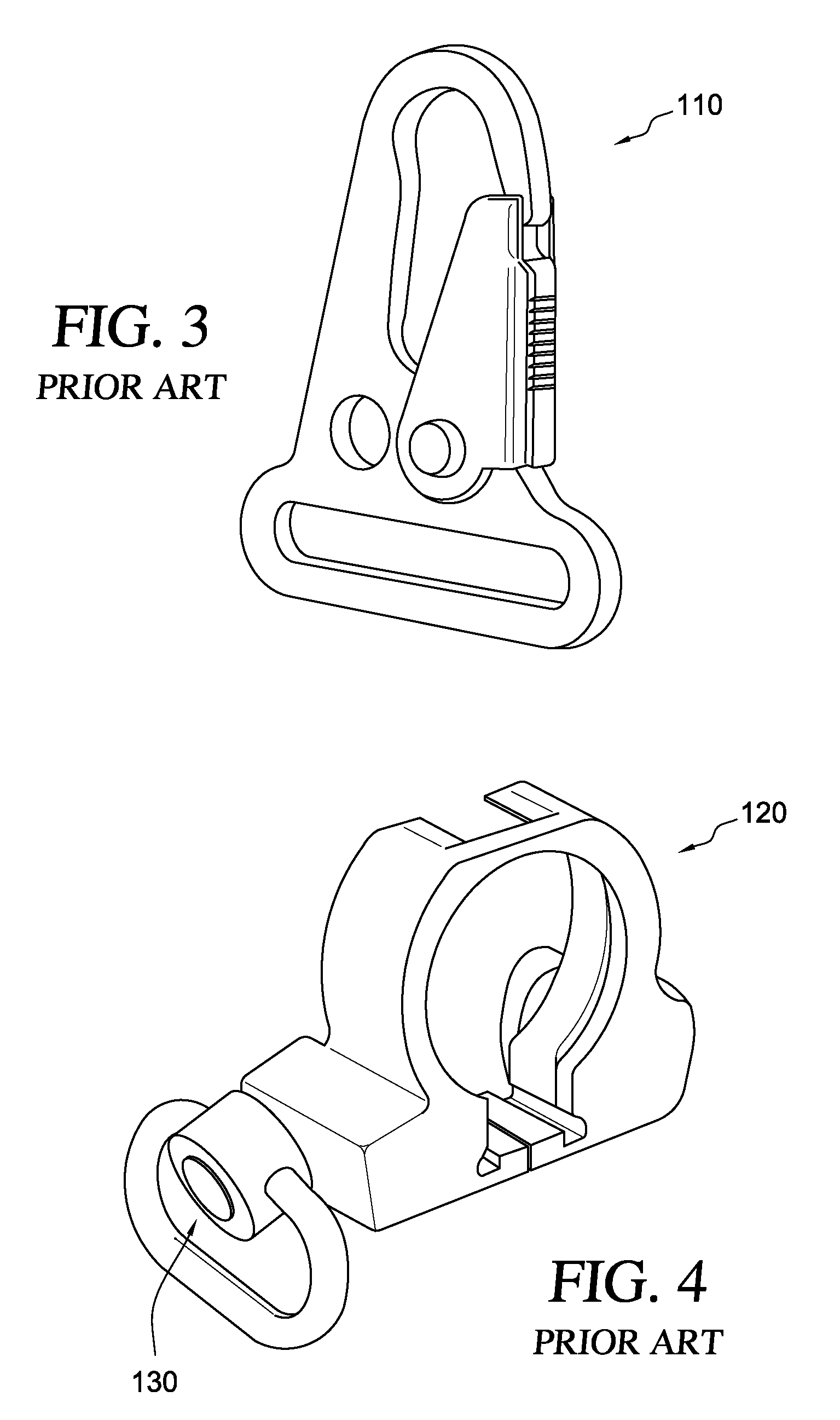

[0051]Turning now to FIGS. 1-9G, a loop-shaped clamping member 200 is illustrated in several views. Loop-shaped clamping member 200 is configured with a transversely projecting boss member 210 which has an aperture 222 therethrough to provide an ideal sling attachment point. A sling such as sling 108 with latching hook 110 as illustrated in FIGS. 2 and 3 is preferred. Boss aperture 222 provides a substantially circular through-bore whose diameter is approximately 0.25″ with chamfered edges at both ends of the through bore, and so provides a snag-free, essentially cylindrical lumen to receive and engage latching hook 110 and to provide a durable and trouble-free sling connection.

[0052]As noted above, vertically slotted sling connection points as used in the prior art give rise to twisted slings and make the rifle (e.g. 100) awkward to handle.

[0053]The loop-shaped clamping member's transversely projecting connection point or boss 210 is horizontal and so allows a single point sling 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com