Shock-absorbing tie brace

a technology of shock absorption and tie brace, which is applied in the direction of building components, building types, constructions, etc., can solve the problems of poor bearing buckling capability of shock absorption tie braces, etc., and achieve the effect of excellent bearing buckling load capability and not easy buckles or bents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

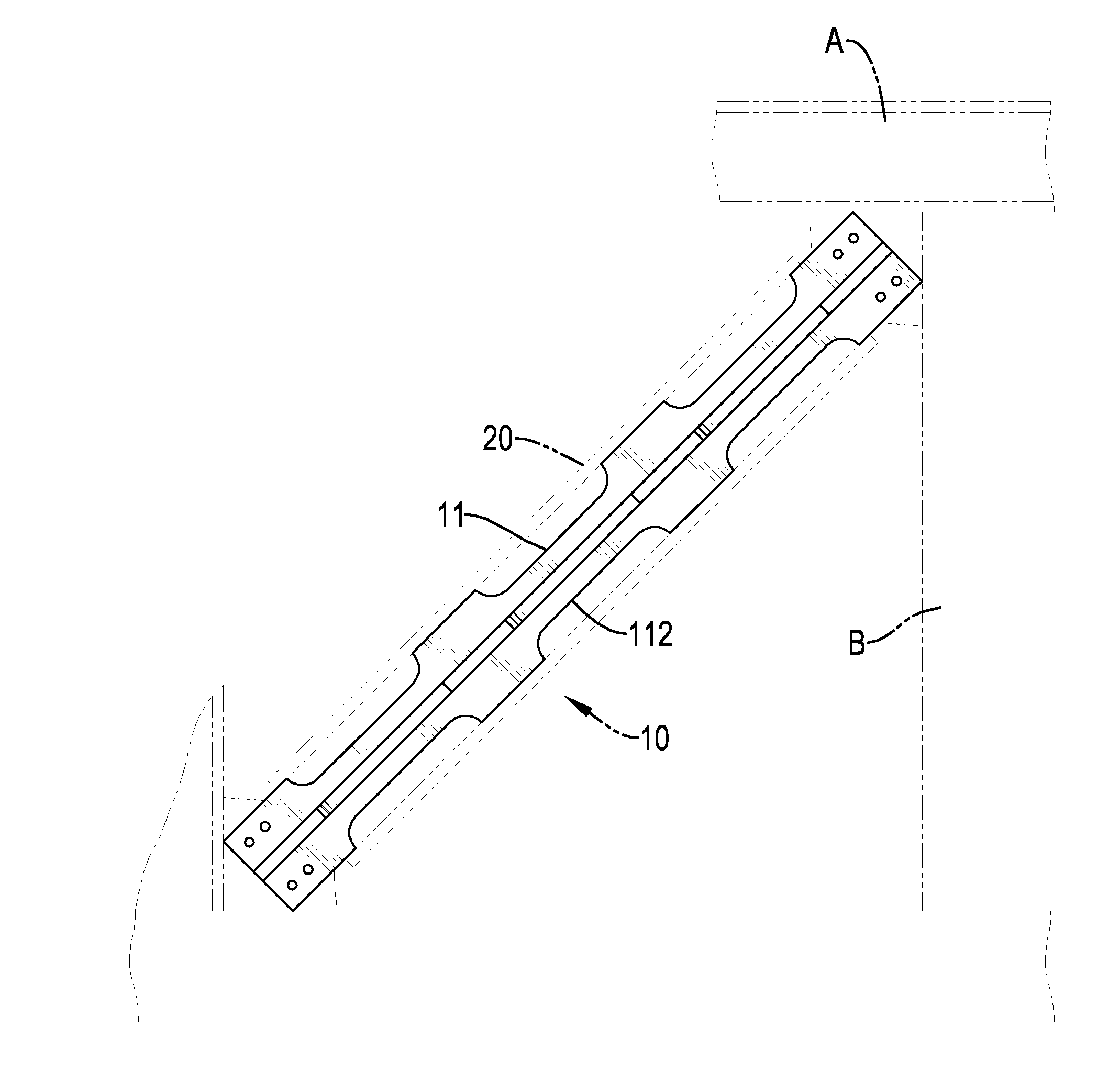

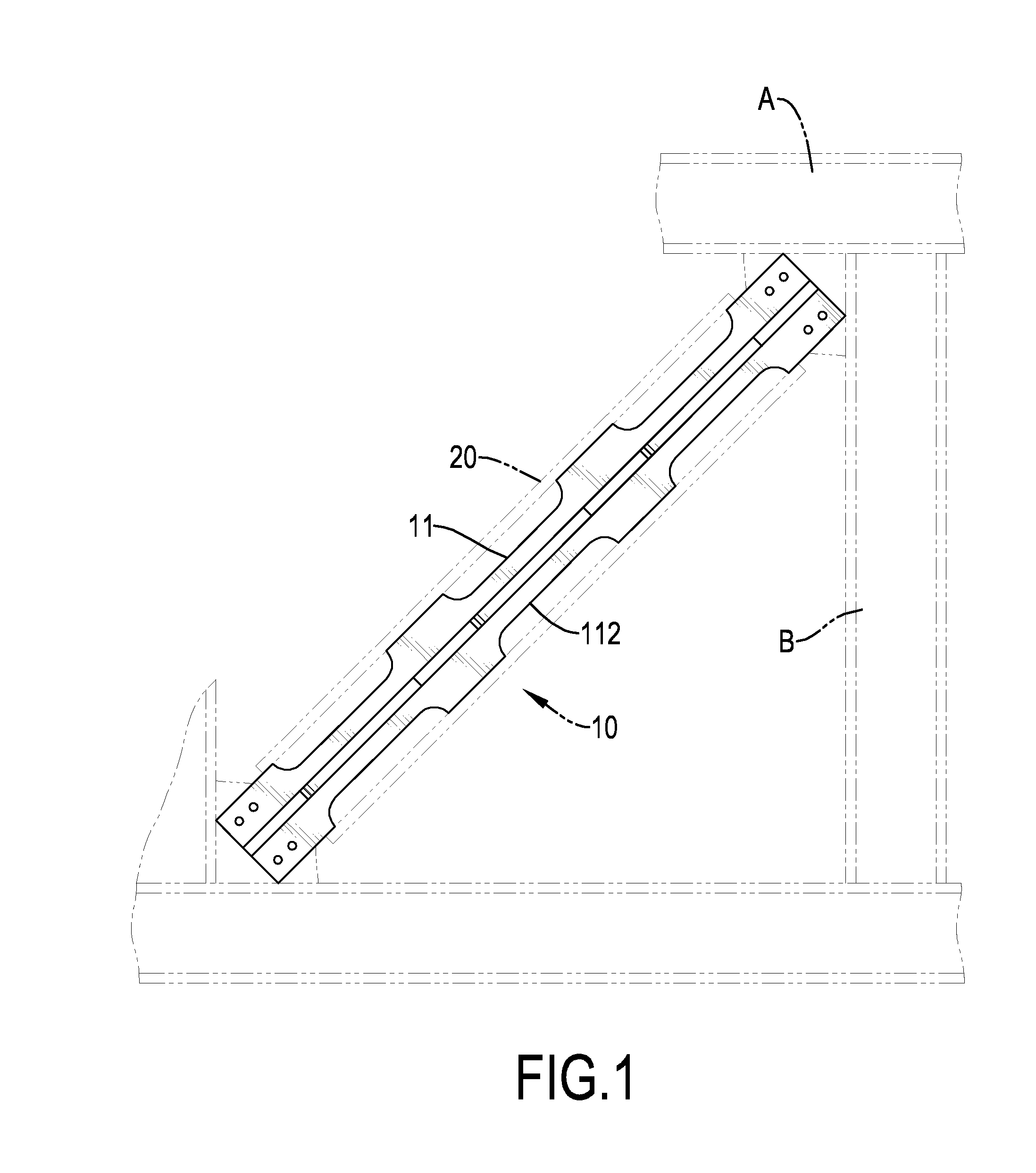

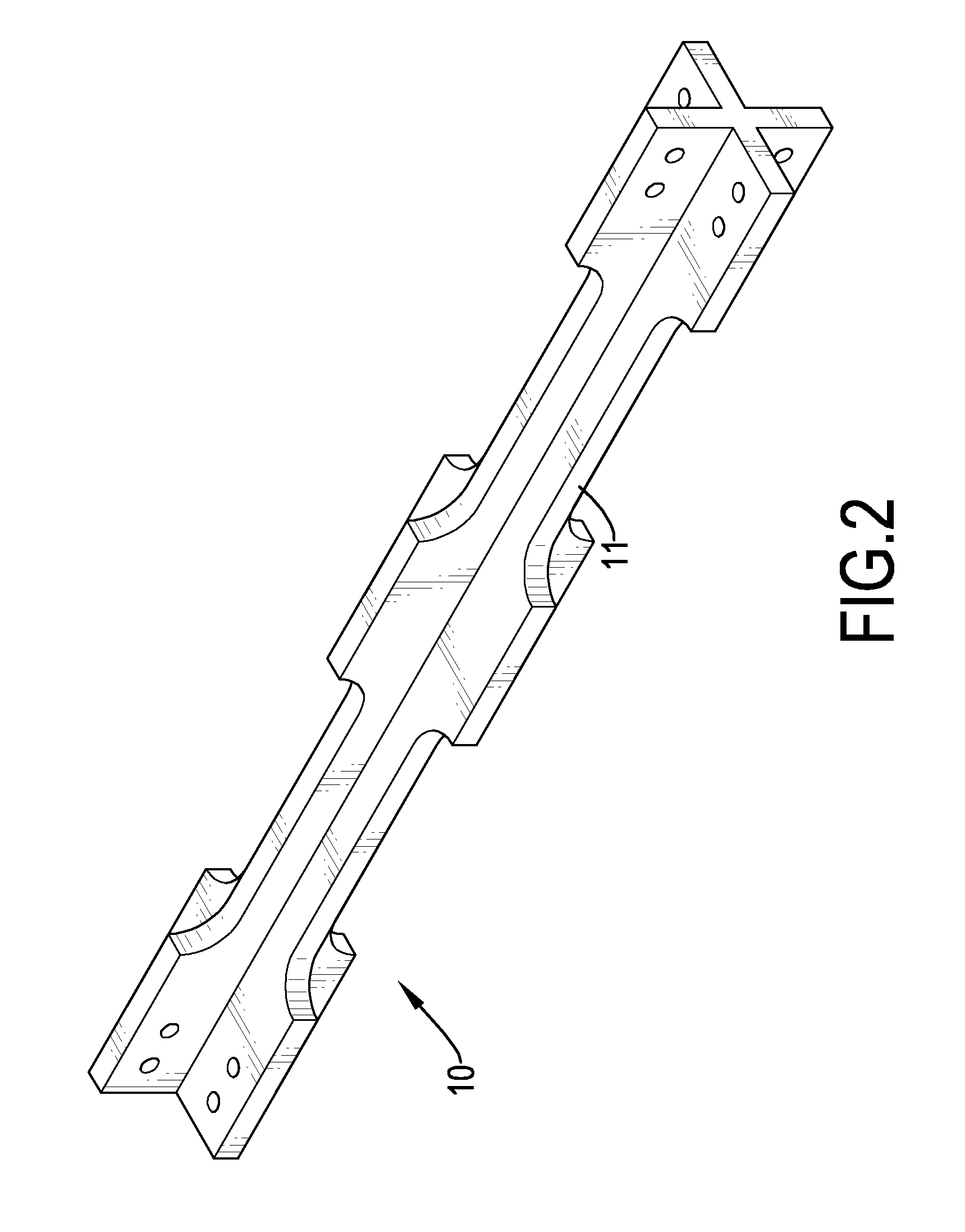

[0055]A shock-absorbing tie brace having a central member with two neck portions in the following dimension scales has been test. The whole length of the central member is 3104 millimeter (mm), the length of each neck portion is 759.27 mm, the height (Hc) of each neck portion to the central line of the central element is 23.85 mm, the length of the enlarged portion is 680 mm and the height (He) of the enlarged portion to the central line of the central element is 113, so that the proportion of the height (Hc) of each neck portion to the height (He) of the enlarged portion is 0.211. The shock-absorbing tie brace is mounted diagonally on a steel structure having beams of 4500 mm in length and columns of 3000 in length, and additional weight of approximately 6936 kg is added to the floor of the steel structure to simulate the load on the floor. The test result is shown in FIGS. 15 to 20. From the test result, the roof acceleration, roof displacement and the column shear force both in X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com