Hair pin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

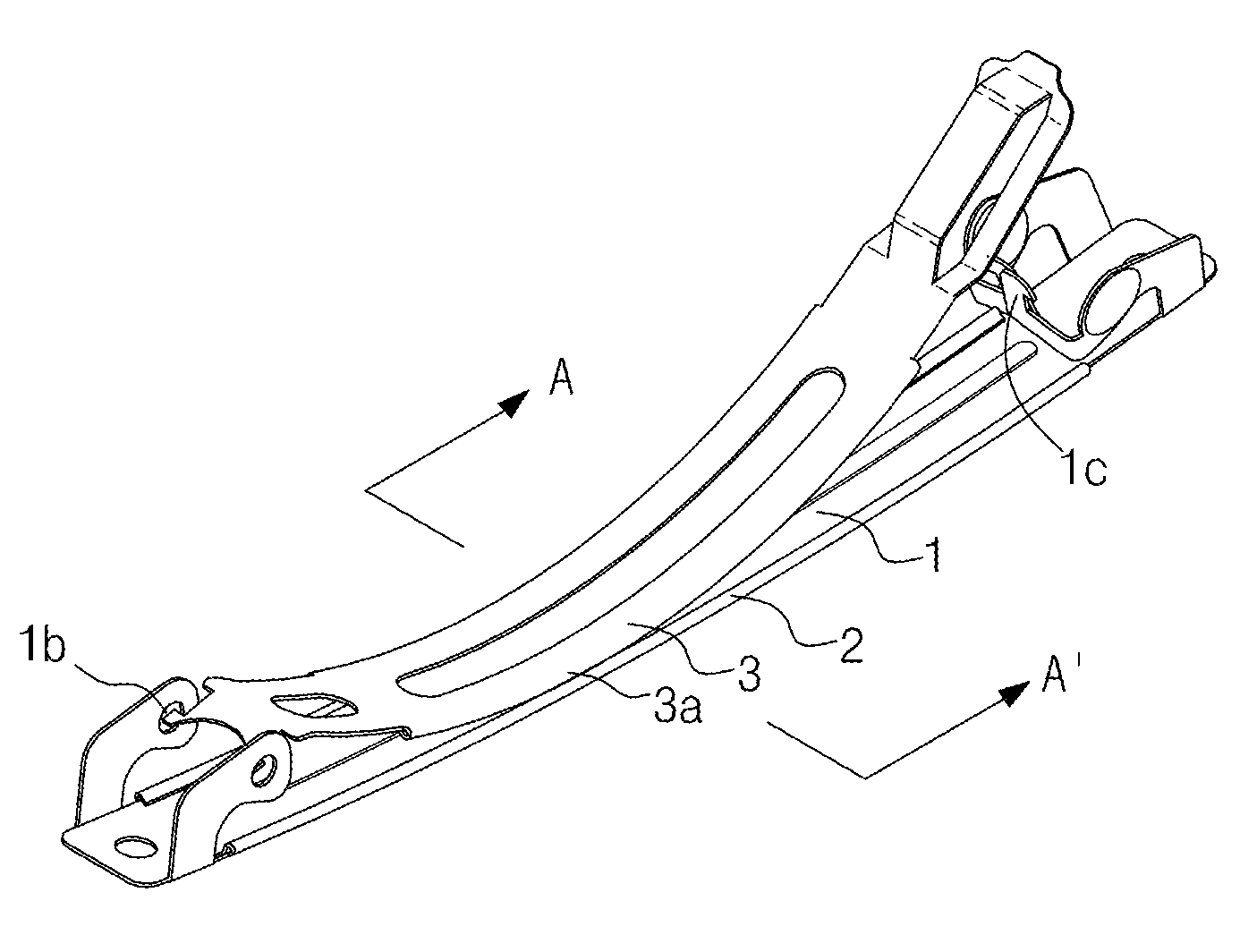

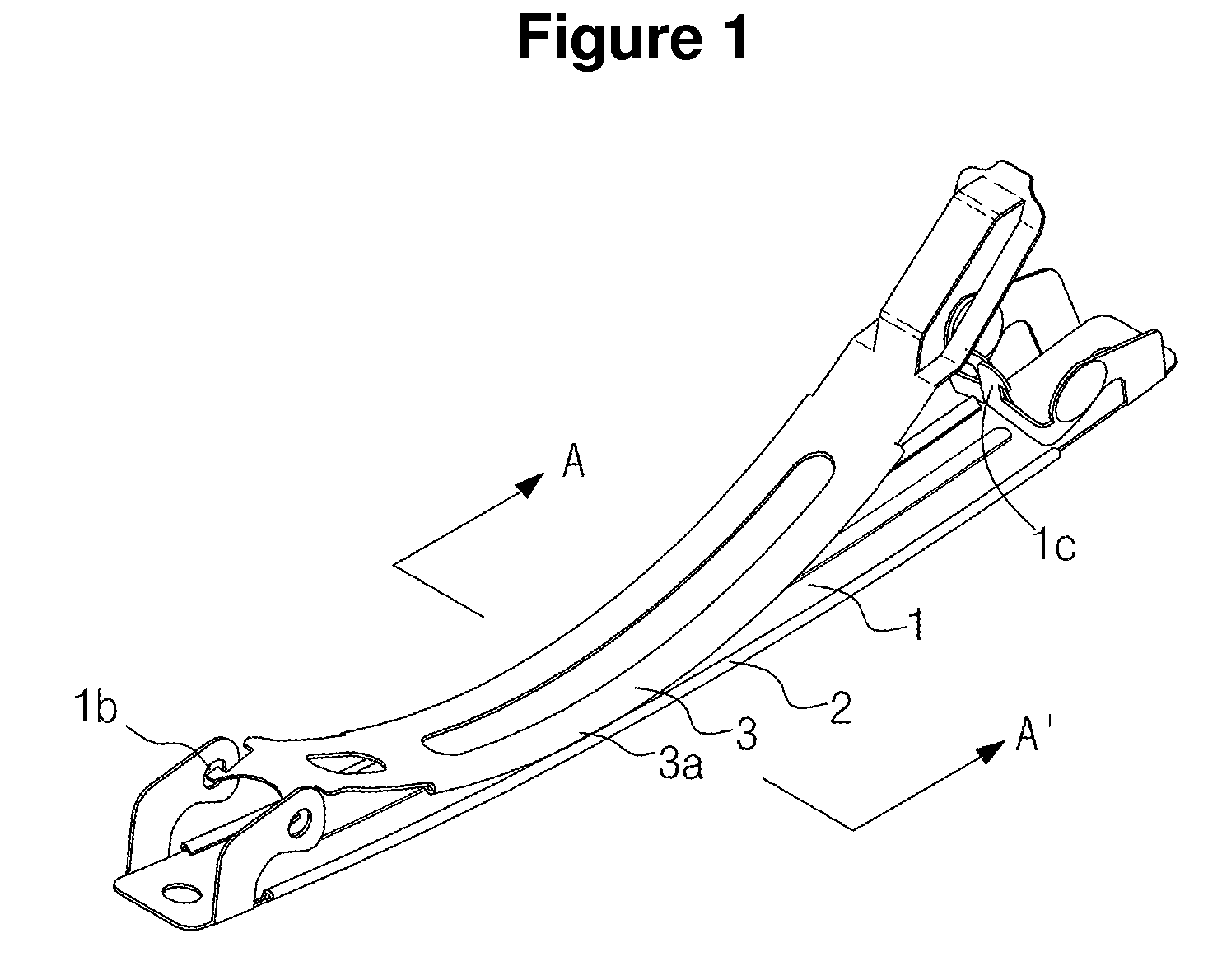

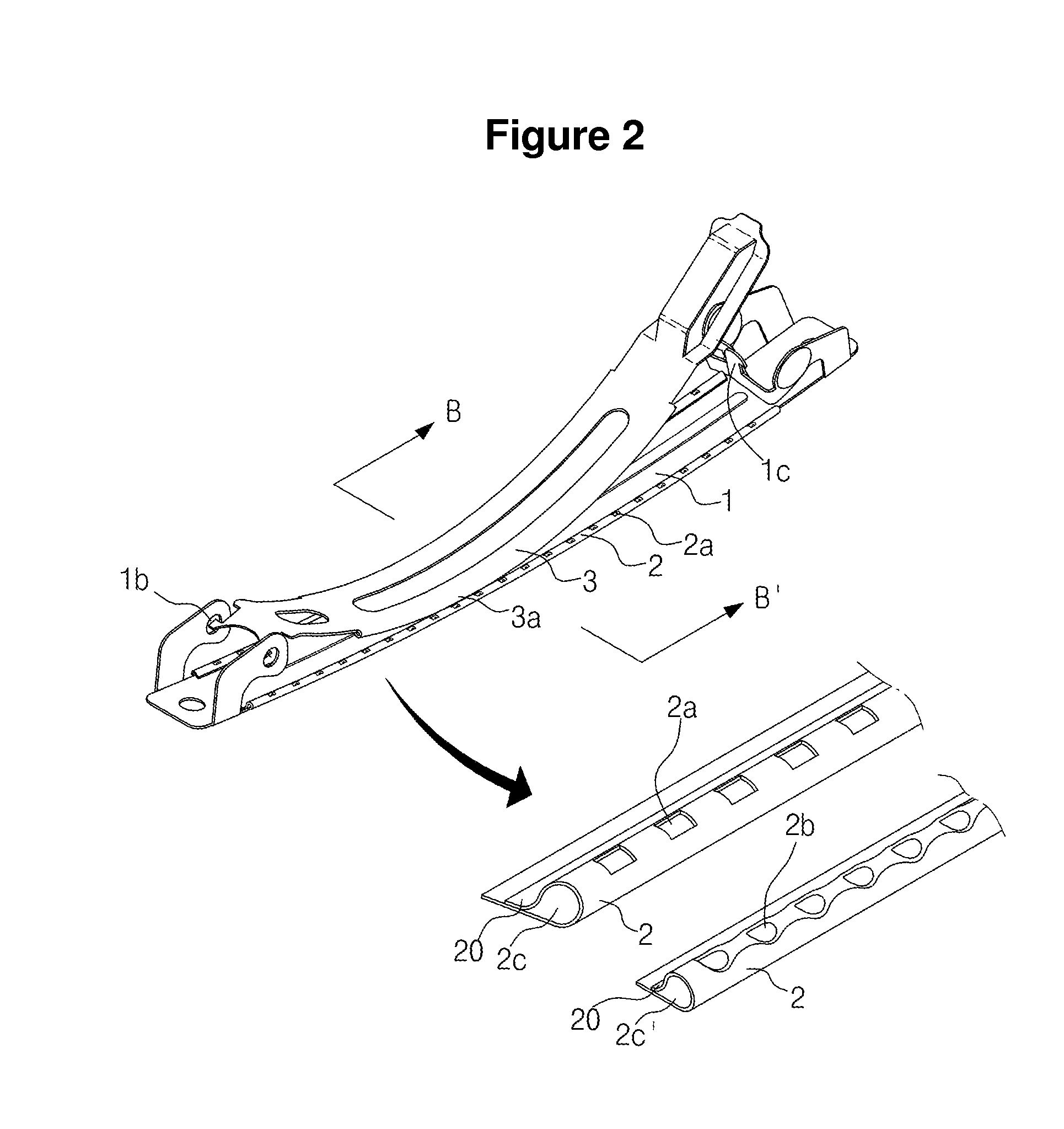

[0019]The preferred embodiments of the present invention will be described with reference to the accompanying drawings.

[0020]In a hair pin which consists of a metallic and elastic hair pin body 1 formed in an arc plate shape, and an elastic metallic compression member 3 which is engaged to a locking part 1c and is formed in an arc plate shape and is more curved than a hair pin body, with the locking part being formed of one end hinged to a hinge part 1b formed in one side of the hair pin body and the other end being formed in another side of the hair pin body, so the elastic metallic compression member is detachable from the locking part, there is provided a hair pin characterized in that an extended protrusion piece with a certain width is formed along both the edge sides of a hair pin body 1, and the extended protrusion piece is rolled inwardly for thereby forming reinforced parts 2 and 2′, and a cut-away groove part 2a or a concave groove part 2b is formed at regular intervals al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com