Double-end threaded body and internally-threaded body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

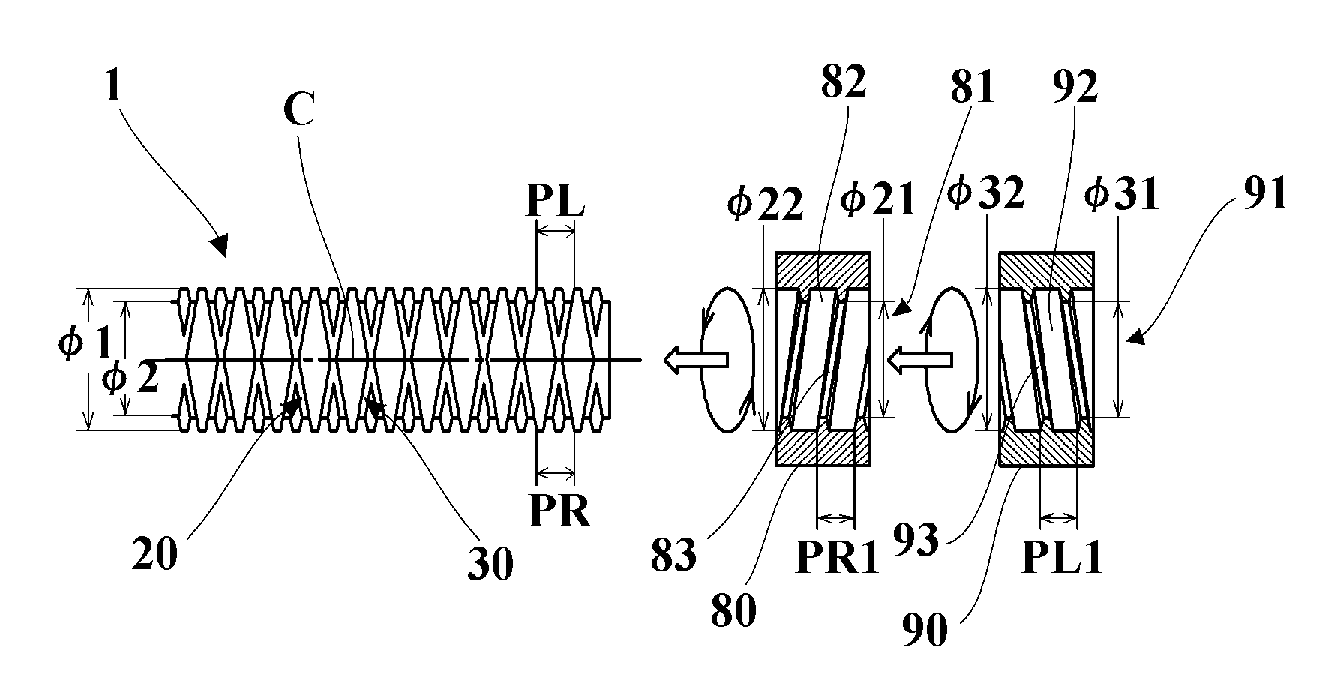

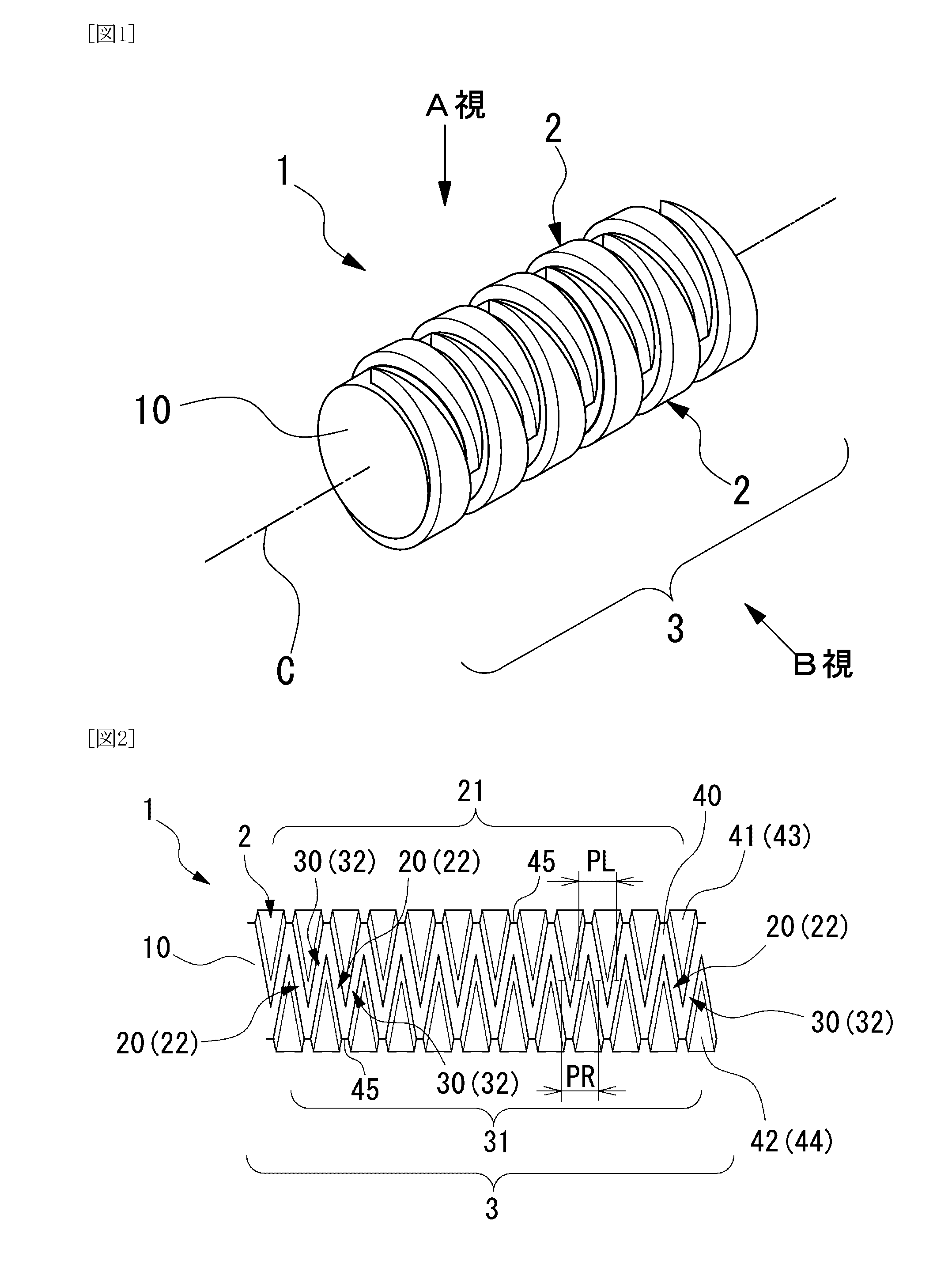

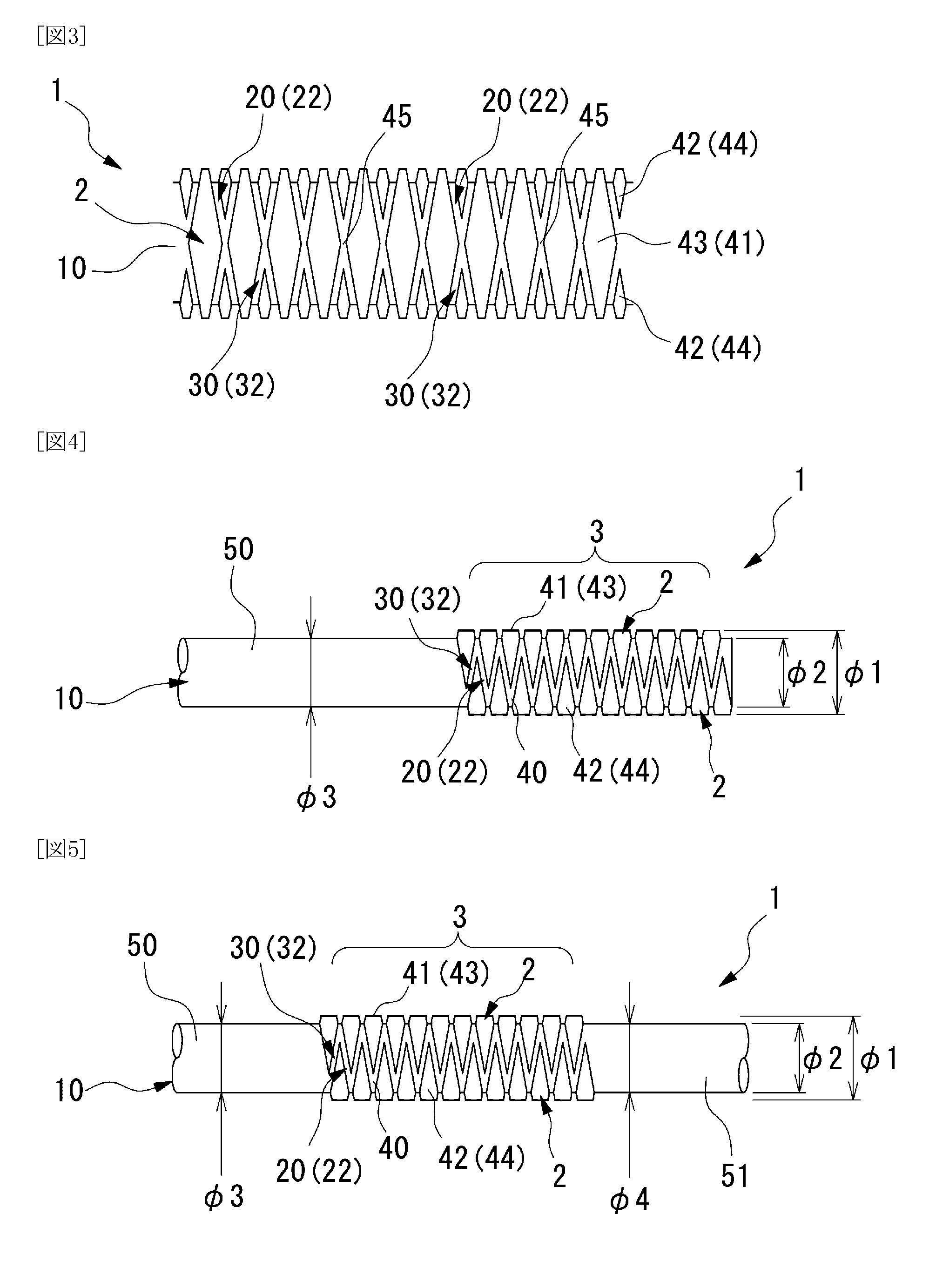

[0416]In a first aspect thereof, a first preferred embodiment of the duplex threaded body of the present invention is explained in detail with reference to the attached drawings (FIGS. 1 to 6) using the example of a duplex threaded body 1 comprised by forming a right-handed thread 20 and a left-handed thread 30 overlapping in the same region on the outer circumferential surface of a rod-like member 10.

[0417]Furthermore, a non-circular end portion (not shown) in the shape of a non-circular hole or non-circular column or non-circular tube may be formed on one end or both ends of the duplex threaded body 1. This non-circular end portion can be formed into the shape of a hexagonal column or hexagonal tube having a hexagonal transverse cross section having an inscribed circle of a diameter equal to or greater than the diameter of the rod-like member 10, or can be in the form of a hexagonal hole and the like provided in the shape of a hexagon on one end of the rod-like member 10 at a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com