Blunt force protection headgear technology

a technology of headgear and blunt force, applied in the field of headgear, can solve the problems of providing little to no protection from momentum transfer, and achieve the effects of enhancing blunt force protection, increasing the weight or balance of the hat, and increasing the protection of blunt for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

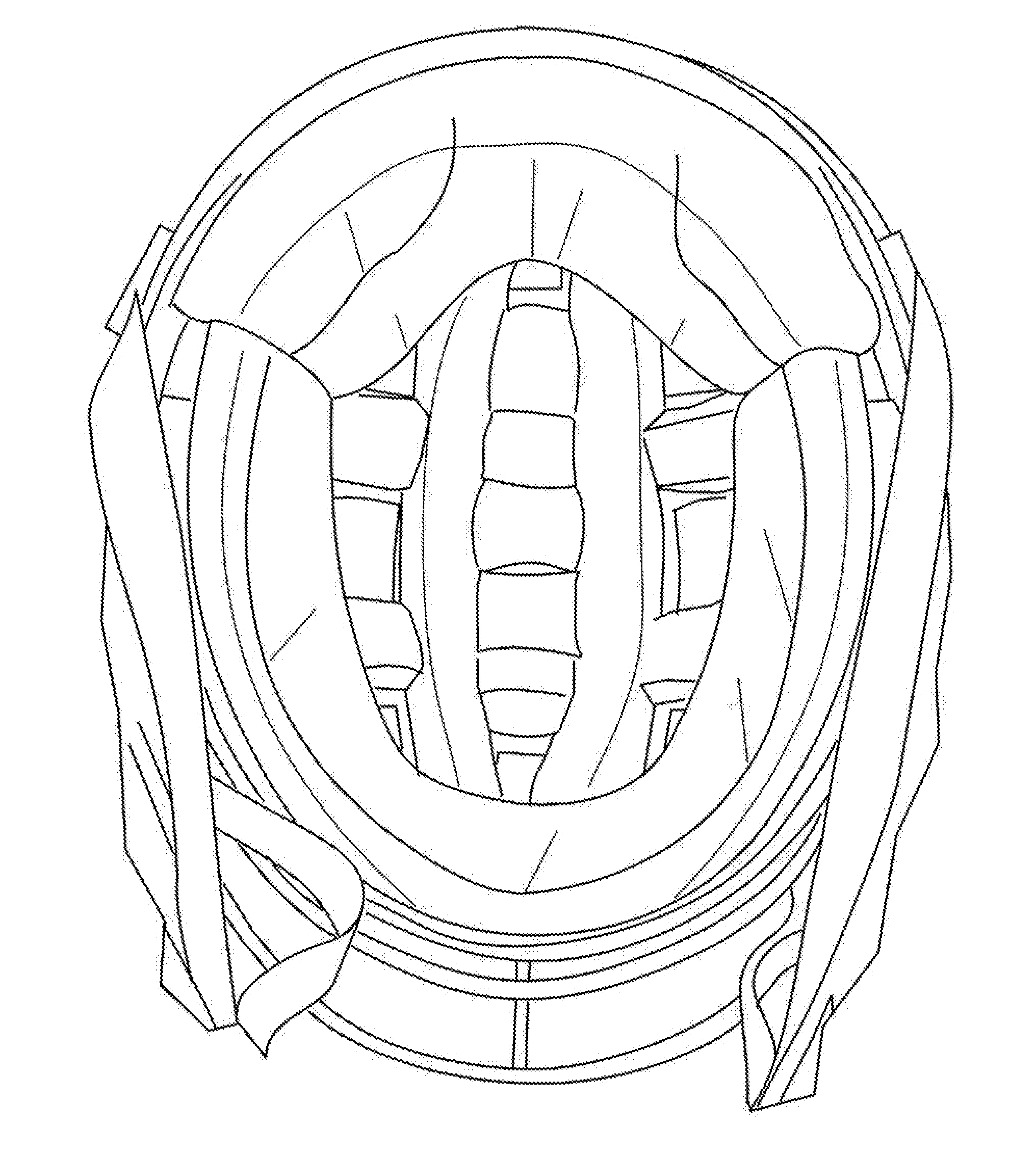

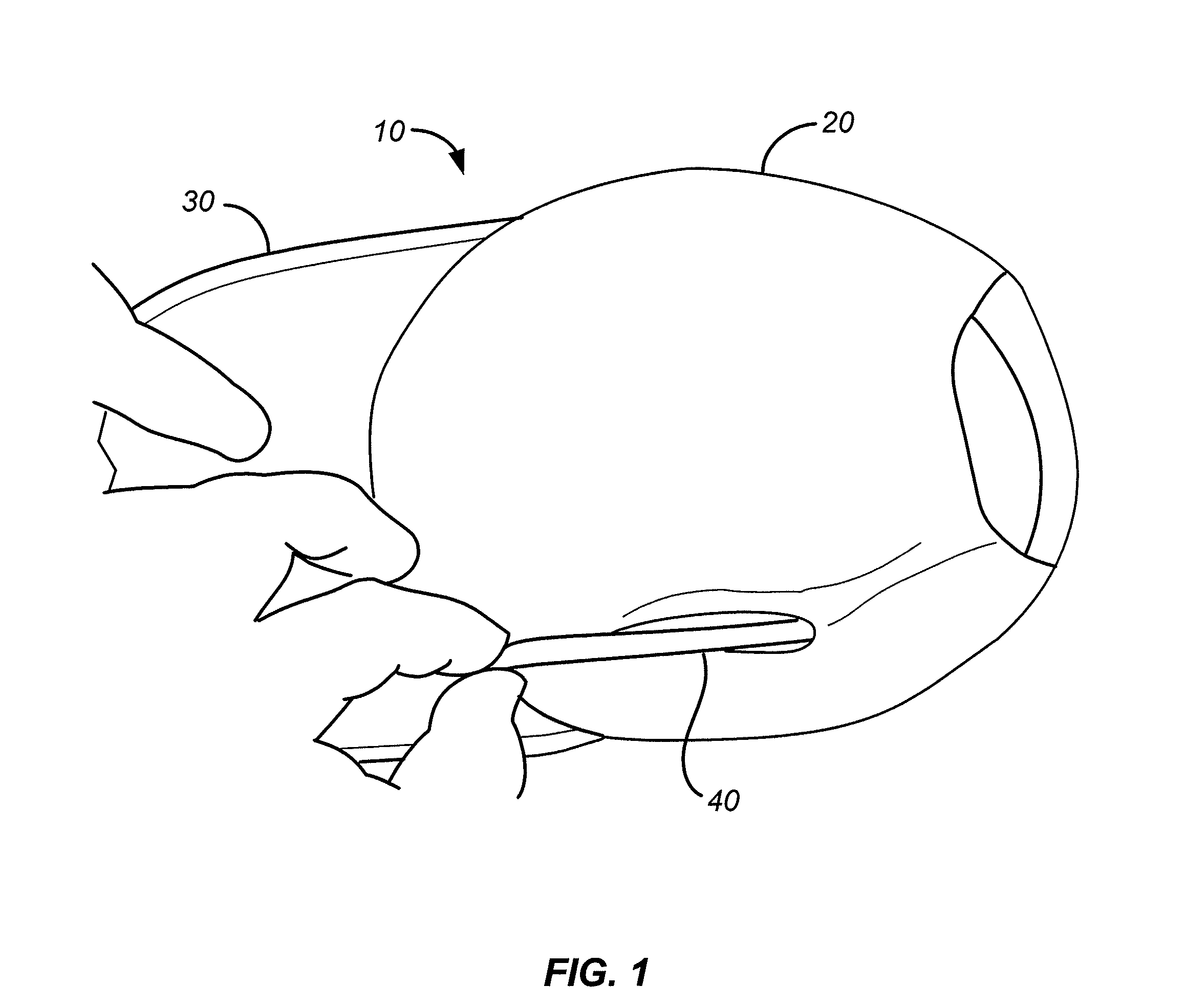

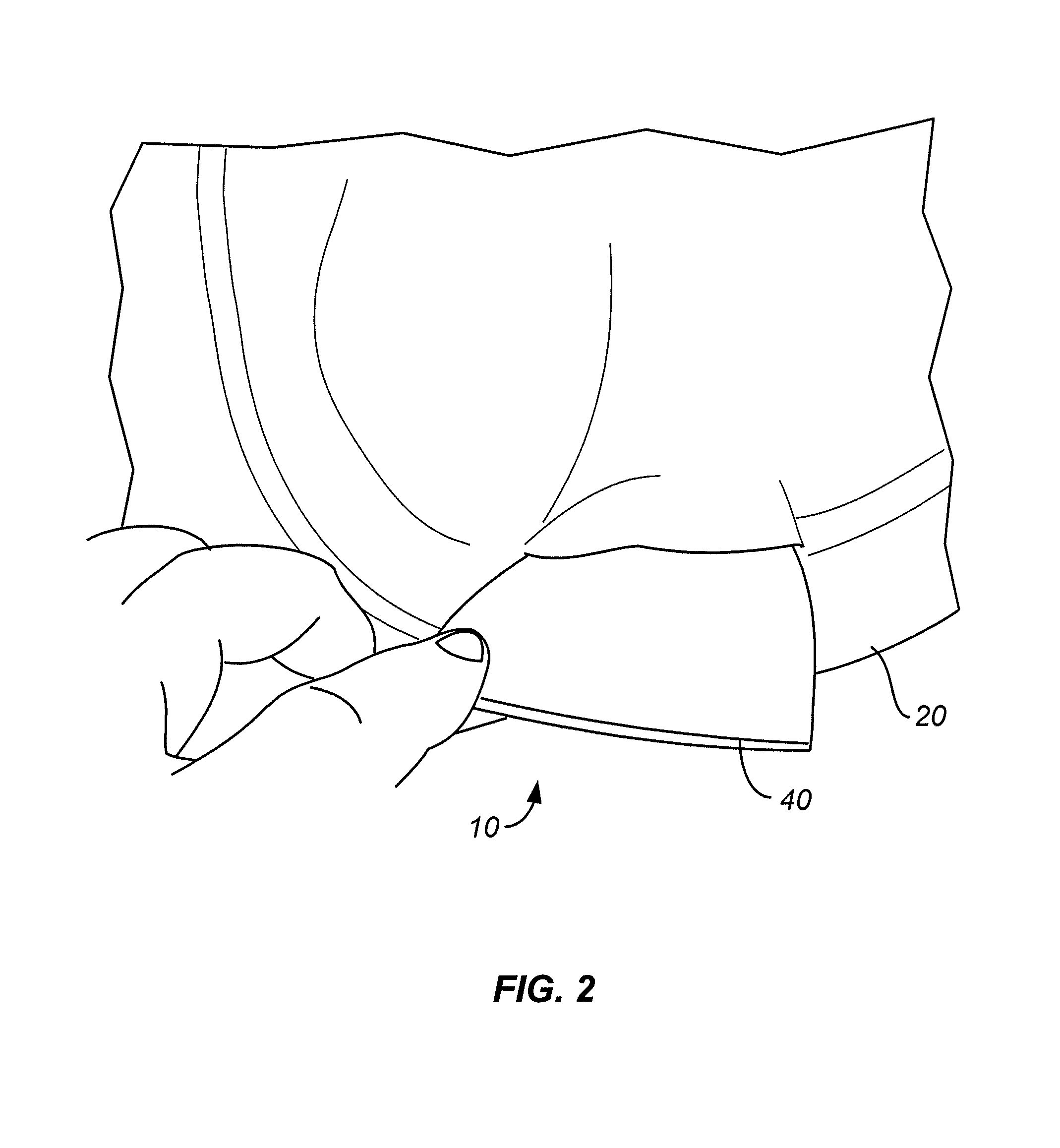

[0017]FIGS. 1-8 illustrate an embodiment of the present invention. It will be appreciated that FIGS. 1-8 illustrate a baseball cap embodiment, however, one skilled in the art will appreciate that embodiments are equally applicable to other types of headgear, such as beanies, caps, or other headgear for use in various applications including military applications, sporting events, etc. As shown in FIG. 1, headgear 10 according to one embodiment includes a cap portion 20 that is configured to cover a wearer's head. Cap portion 20 is typically made of a fabric material, such as a stitched cotton fabric. Cap portion may include various mechanisms as are well known to adjust the size of the perimeter to allow better coupling / attachment with different size heads, such as an elastic portion, Velcro, a belt and clasp mechanism, etc. Visor portion 30 is coupled with the cap portion. Visor portion 30 is optional in certain embodiments, e.g., beanies and other caps.

[0018]In one embodiment, a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com