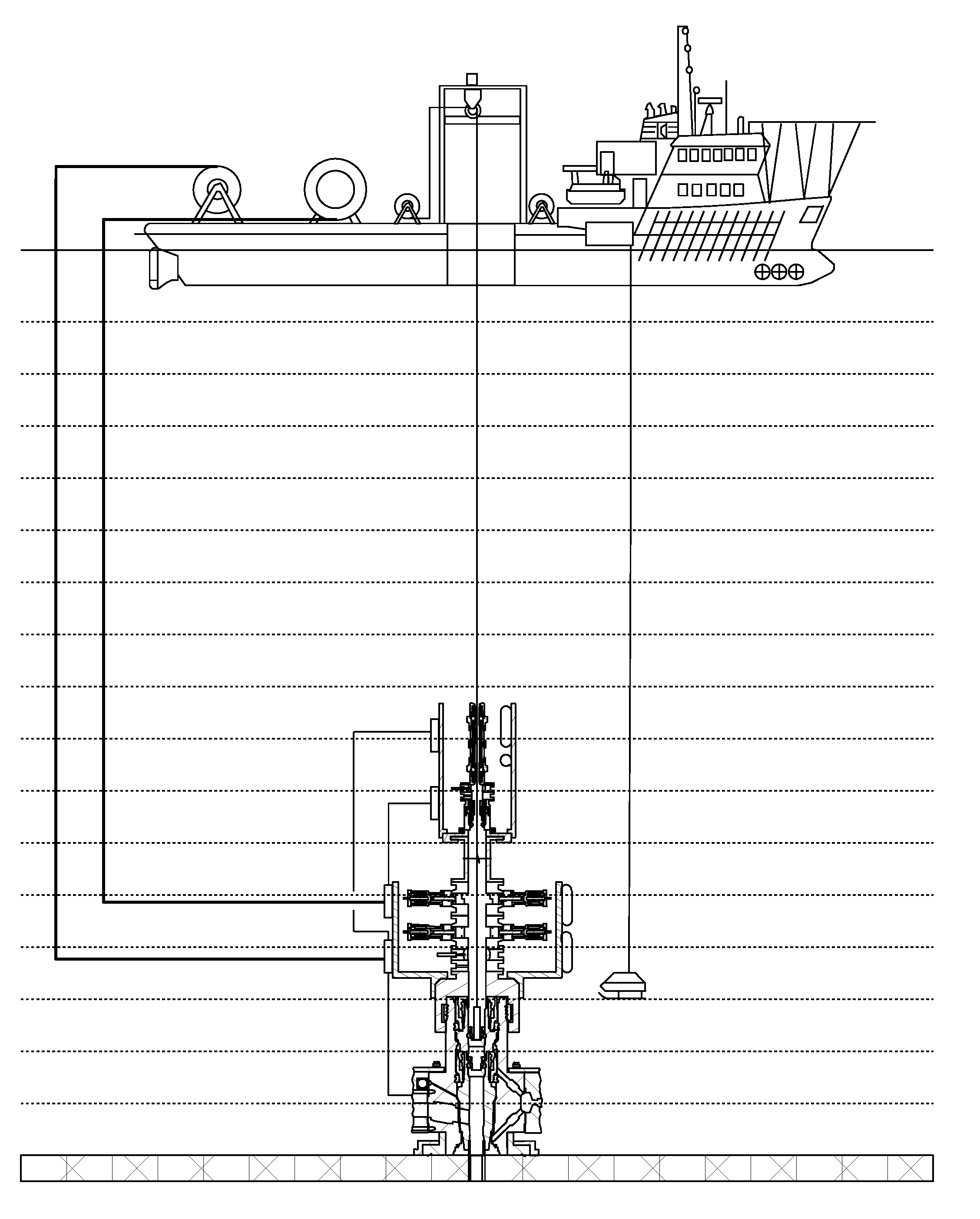

Coiled tubing module for riserless subsea well intervention system

a technology of risers and modules, applied in the direction of drilling pipes, wellbore/well accessories, sealing/packing, etc., can solve the problems of large, complex installation, and inconvenient installation of risers, and achieve the risers needed, and the risers are not easy to be rolled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

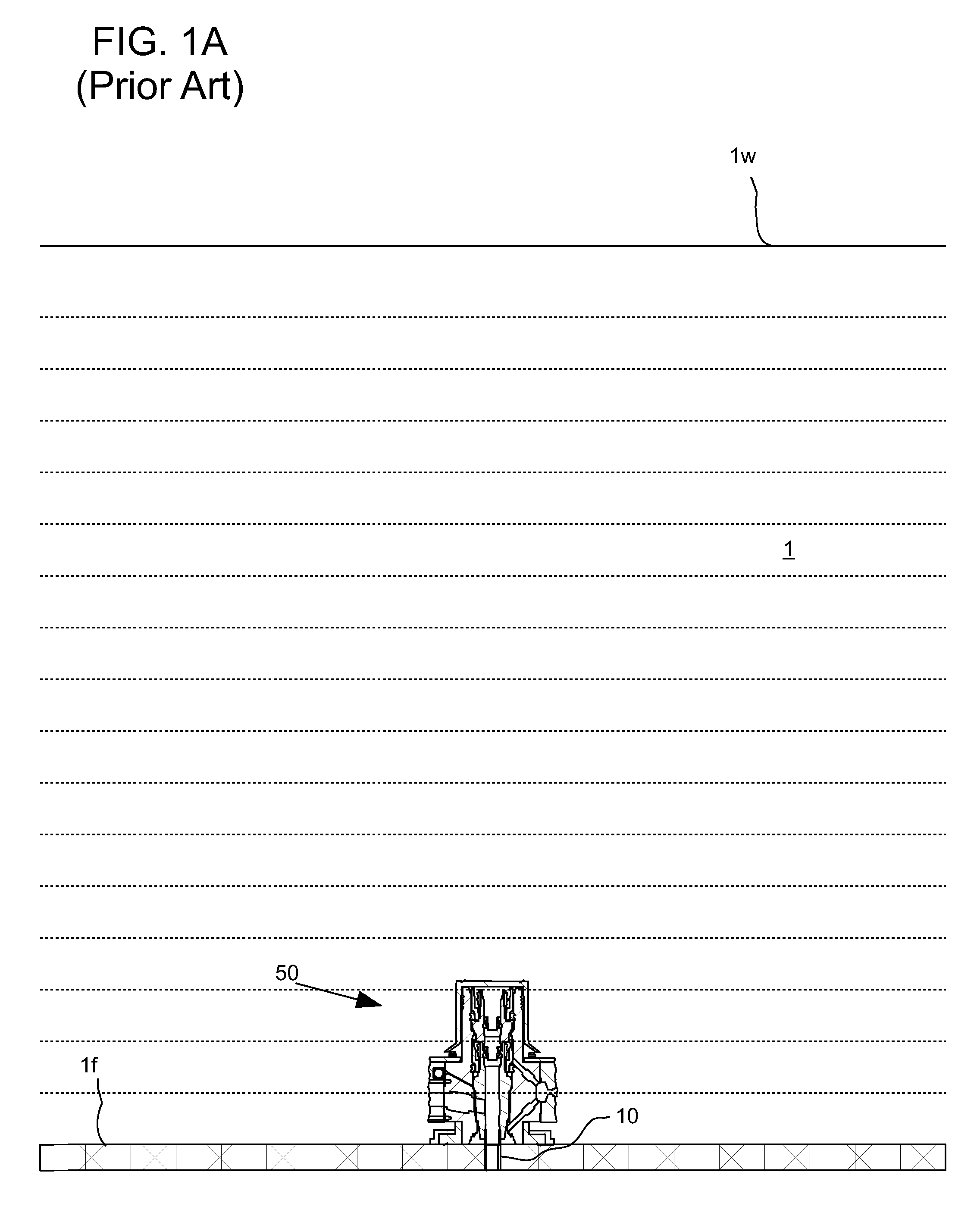

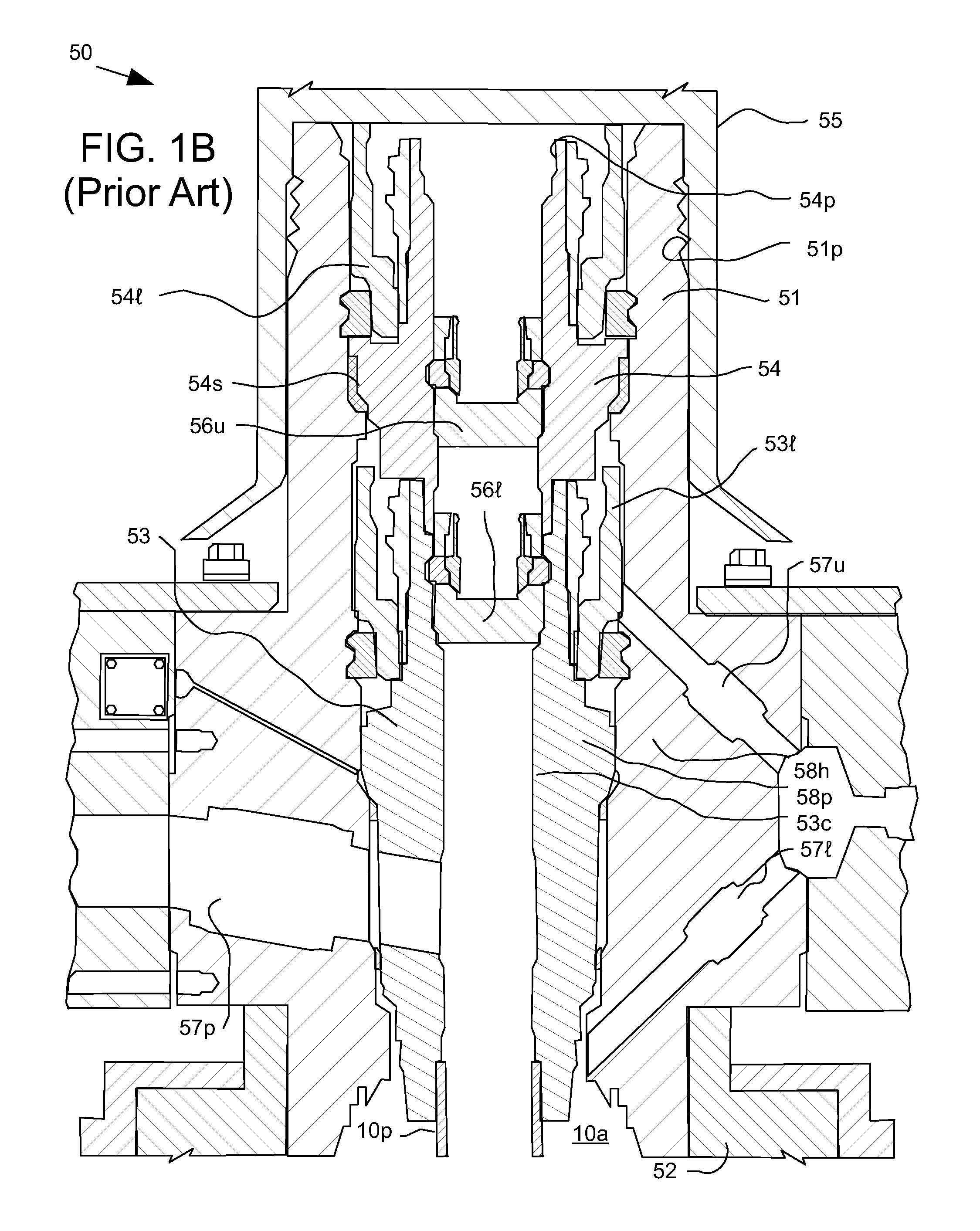

[0020]FIG. 2A illustrates a pressure control assembly (PCA) 100, according to one embodiment of the present invention. The PCA 100 may include a tree adapter 105, a fluid sub 110, an isolation valve 115, a blow out preventer (BOP) stack 120, a tool housing (aka lubricator riser) 125, a frame 130, a control pod 135, a manifold 140, and one or more accumulators 145 (two shown). The tree connector 105, fluid sub 110, isolation valve 115, BOP stack 120, and tool housing 125 may each include a housing or body having a longitudinal bore therethrough and be connected, such as by flanges, such that a continuous bore is maintained therethrough. The bore may have a large drift diameter, such as greater than or equal to four, five, six, or seven inches to accommodate a bottom hole assembly (BHA) of a workstring (discussed more below) and the crown plugs 56u,l of the tree 50.

[0021]The tree adapter 105 may include a connector, such as dogs 105d, for fastening the PCA 100 to an external profile 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com