Sink With Integrated Work Surface

a work surface and sink technology, applied in water installations, cabinets, constructions, etc., can solve the problems of affecting the quality of food, the inability to add extra contamination to the meat, and the inconvenient placement of food at the bottom of the sink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

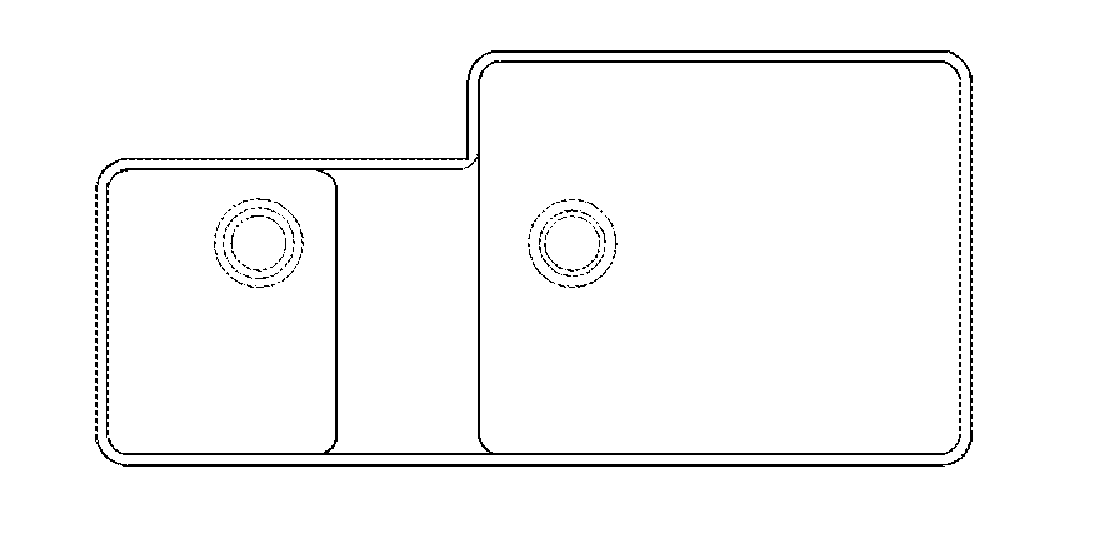

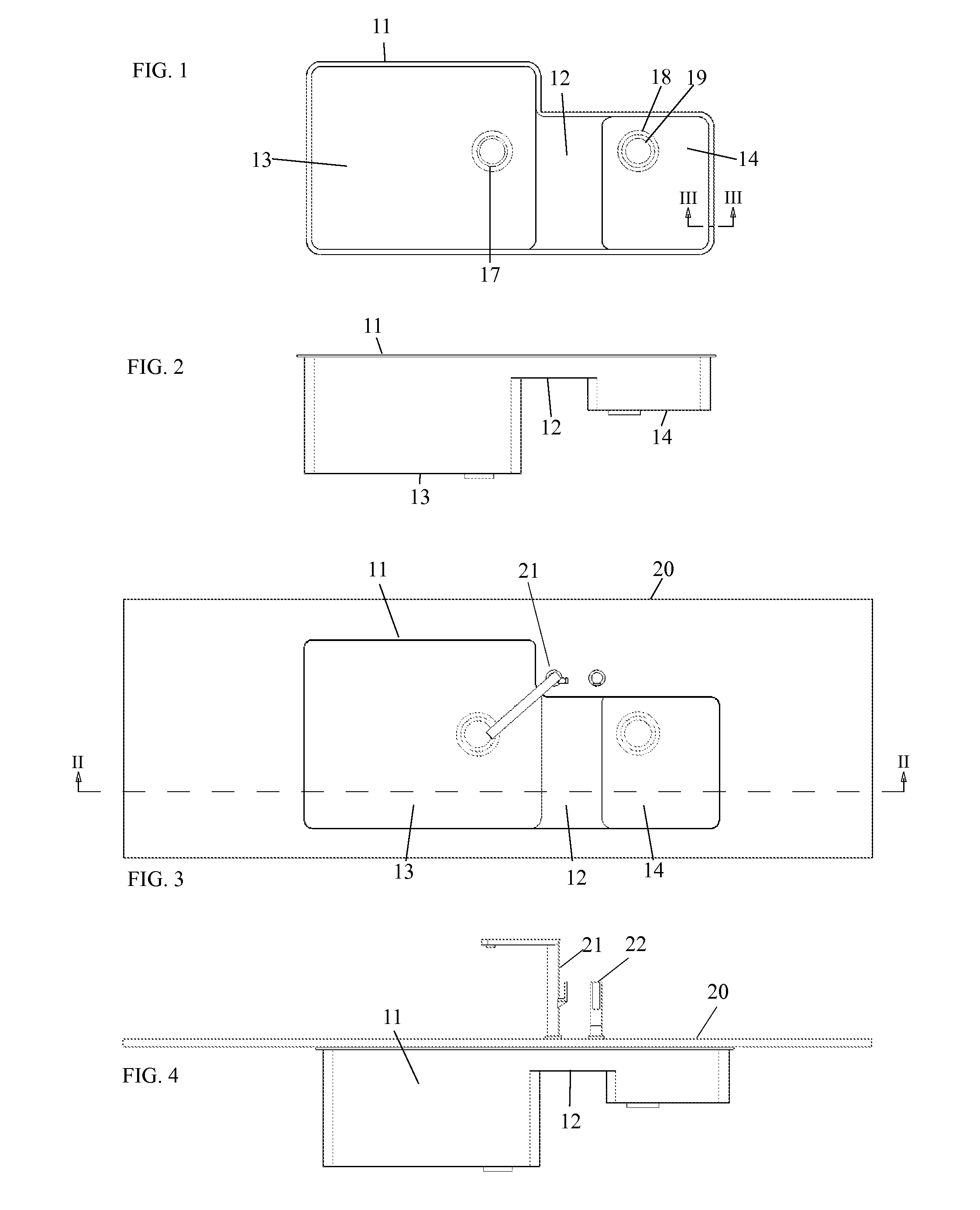

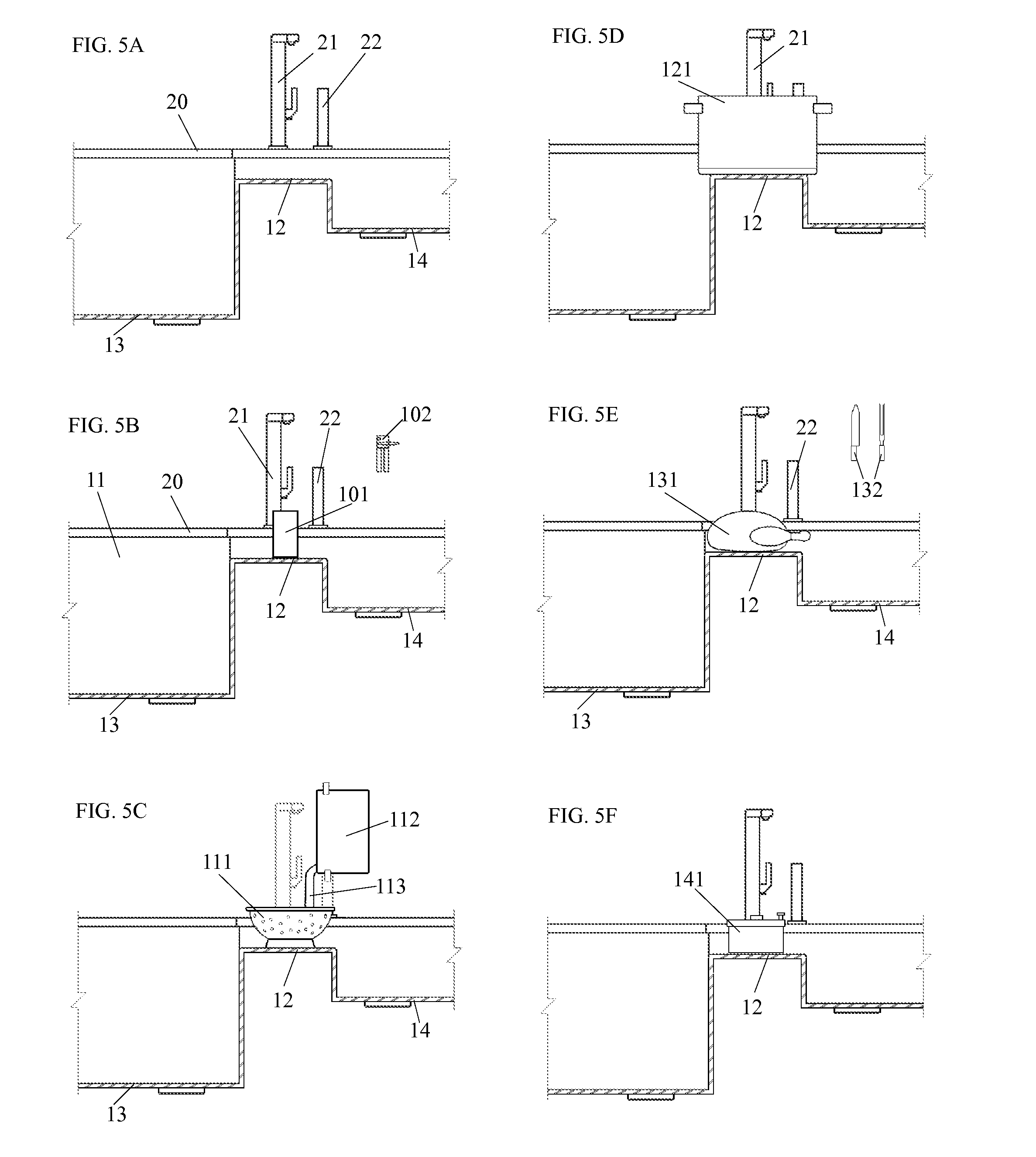

[0035]Referring to the drawings in detail, FIG. 1 illustrates how, as part of the kitchen sink 11, the work surface 12 stands between basin 13 and 14 and spans entirely across the central part of the sink 11 from front to back, thus dividing the two basins 13 and 14 which have their own drains 17 and 18 respectively. A garbage disposal 19 is attached to drain 18 in the first embodiment as shown in FIG. 1.

[0036]In FIG. 2, the multi-purpose work surface12 is shown at a level lower than the top edge of sink 11, but still higher than both sink basins 13 and 14. Having the work surface at a lower level than the top of the edge of the sink helps contain the liquid that will land on and flow over the work surface into the basins. As can be seen in FIG. 2, the form of and around the elevated work surface 12 also serves as the divider between basins 13 and 14.

[0037]Sink 11 is connected to an opening in the counter top 20 in FIG. 3. The opening of counter top 10 is shaped as to allow access t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap