Collapsible container with pockets

a container and pocket technology, applied in the field of collapsible containers with pockets, can solve problems such as difficulty in discharging containers from the trunk bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

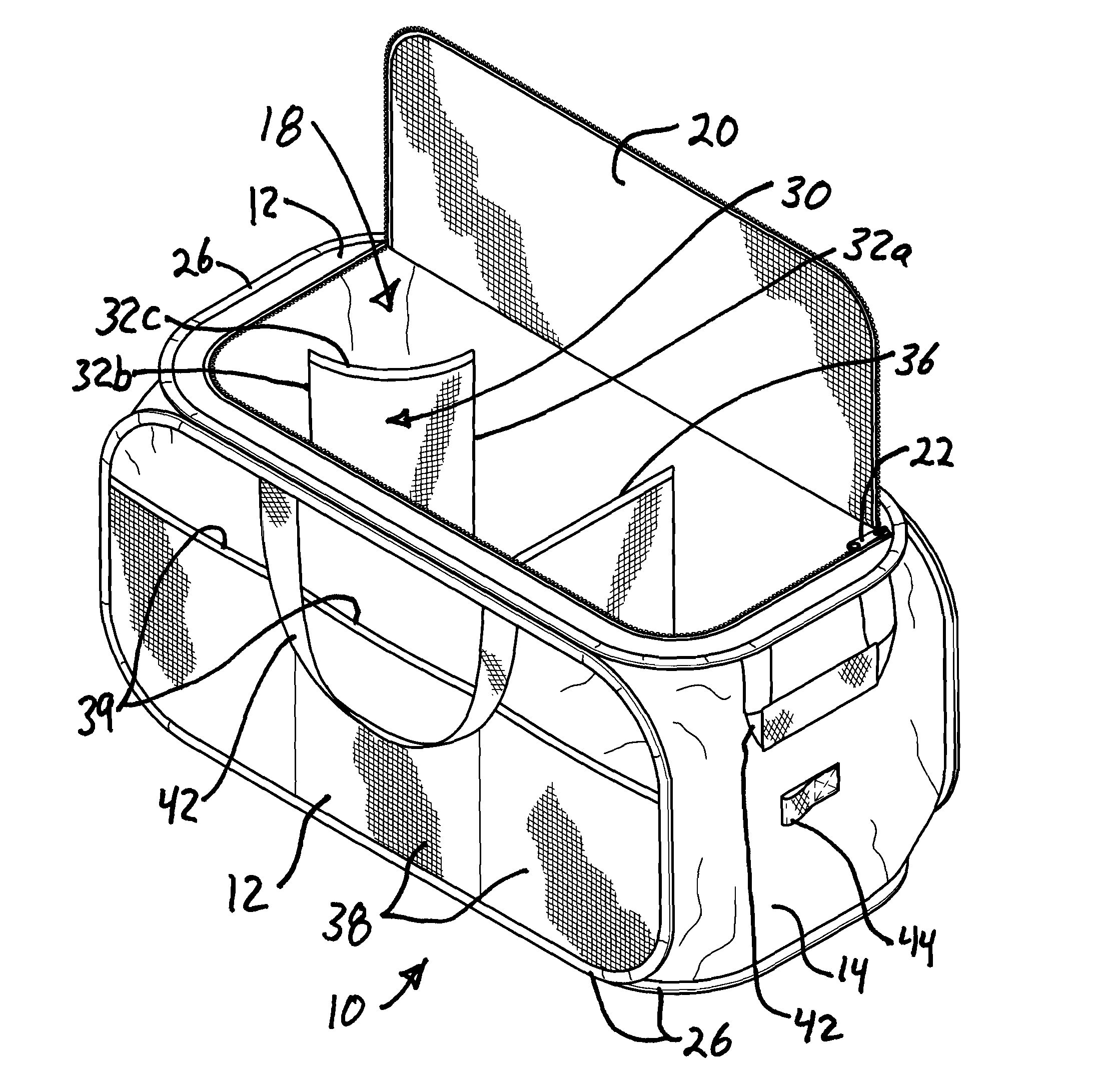

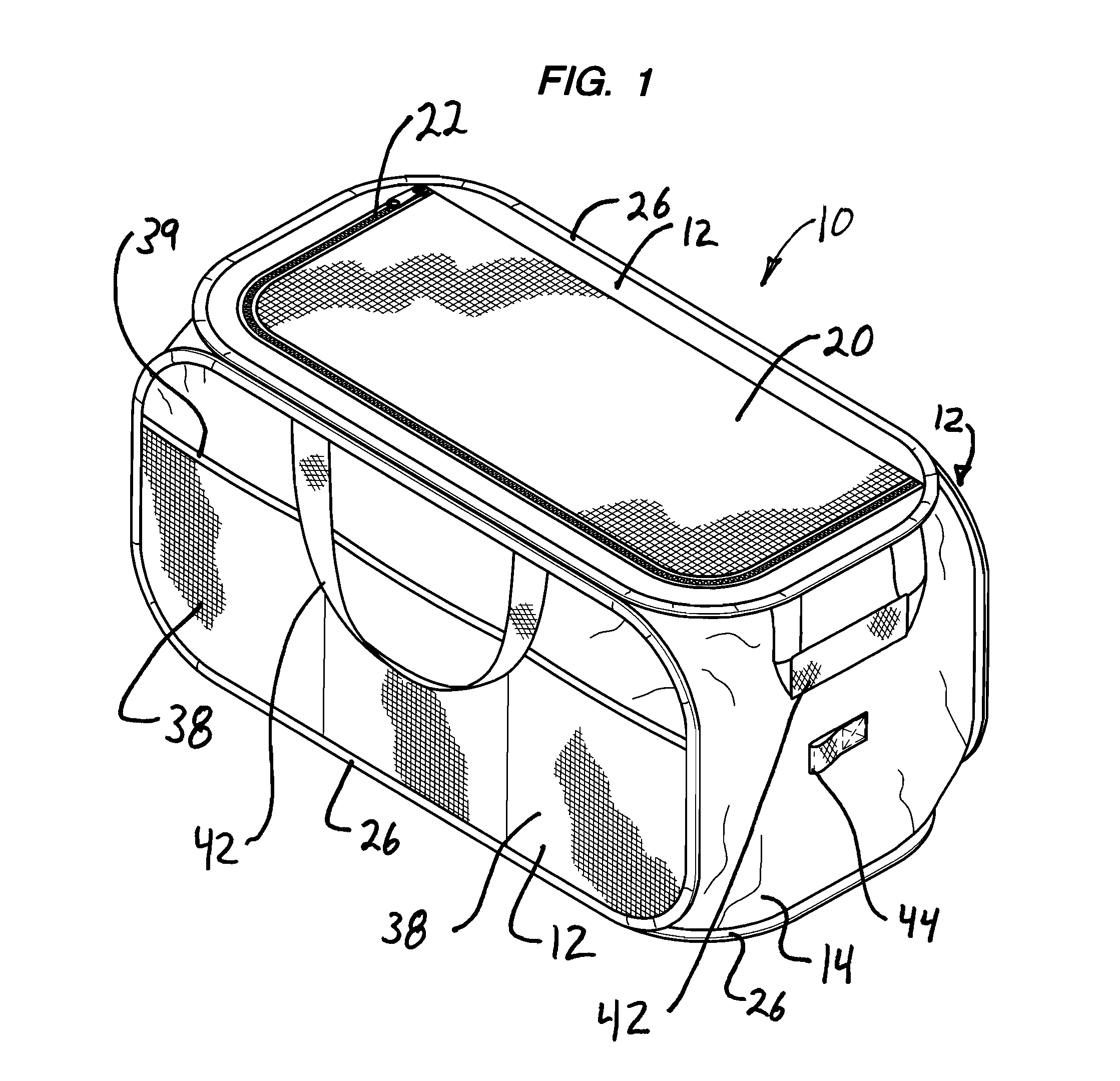

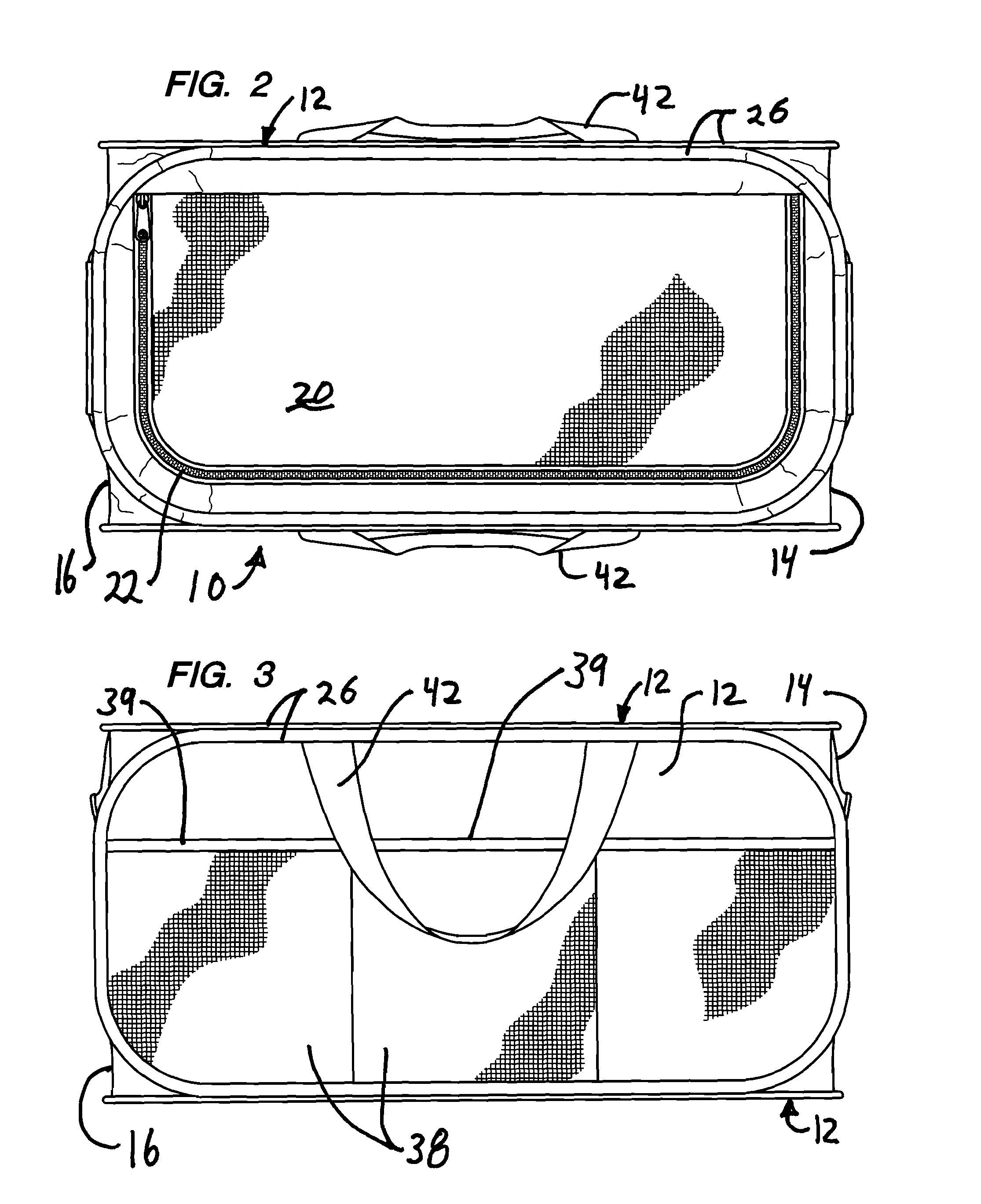

[0028]Referring to FIGS. 1-6, a collapsible container 10 is provided having at four panels 12 connected to opposing ends 14 and 16. An opening 18 is formed in one of the panels 12 or ends 14, 16 to allow access to the inside of the container with a releasable cover or lid 20 covering the opening. A releasable fastener 22 such as a zipper releasably fastens the cover 20 to the top 18. Other releasable fasteners can be used, such as toggles, snaps, buttons, hook and loop fasteners, etc.

[0029]Each panel 12 is connected to a tension loop frames 24 (FIG. 9) which holds the side panels 12 taut during use. Typically the loop frames 24 are made of spring metal or made of plastic, and have circular or rectangular cross sections, although various cross-sectional shapes and materials can be used. The loop frames 24 and side panels 12 are preferably, but optionally, generally rectangular in shape, with the long side horizontal. The side panel frames 24 are joined along the long, horizontal side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com