Accordion bottle

a technology of accordion and bottle, which is applied in the direction of transportation and packaging, liquid transferring devices, manufacturing tools, etc., can solve the problems of air or other unwanted fluids entering the container, known devices are not capable of preventing the container from expanding, etc., and achieve the effect of reducing the internal volume of the container and internal volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

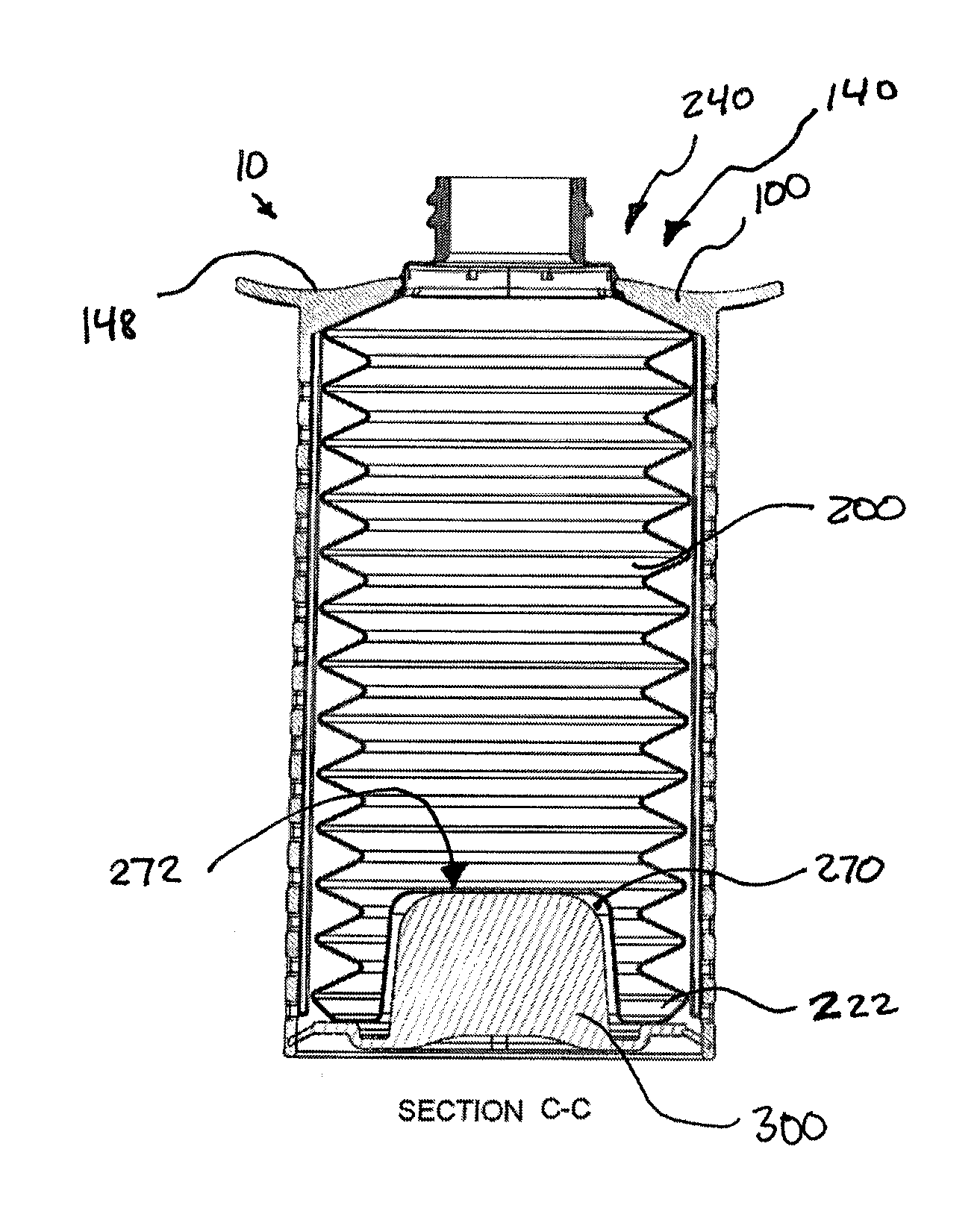

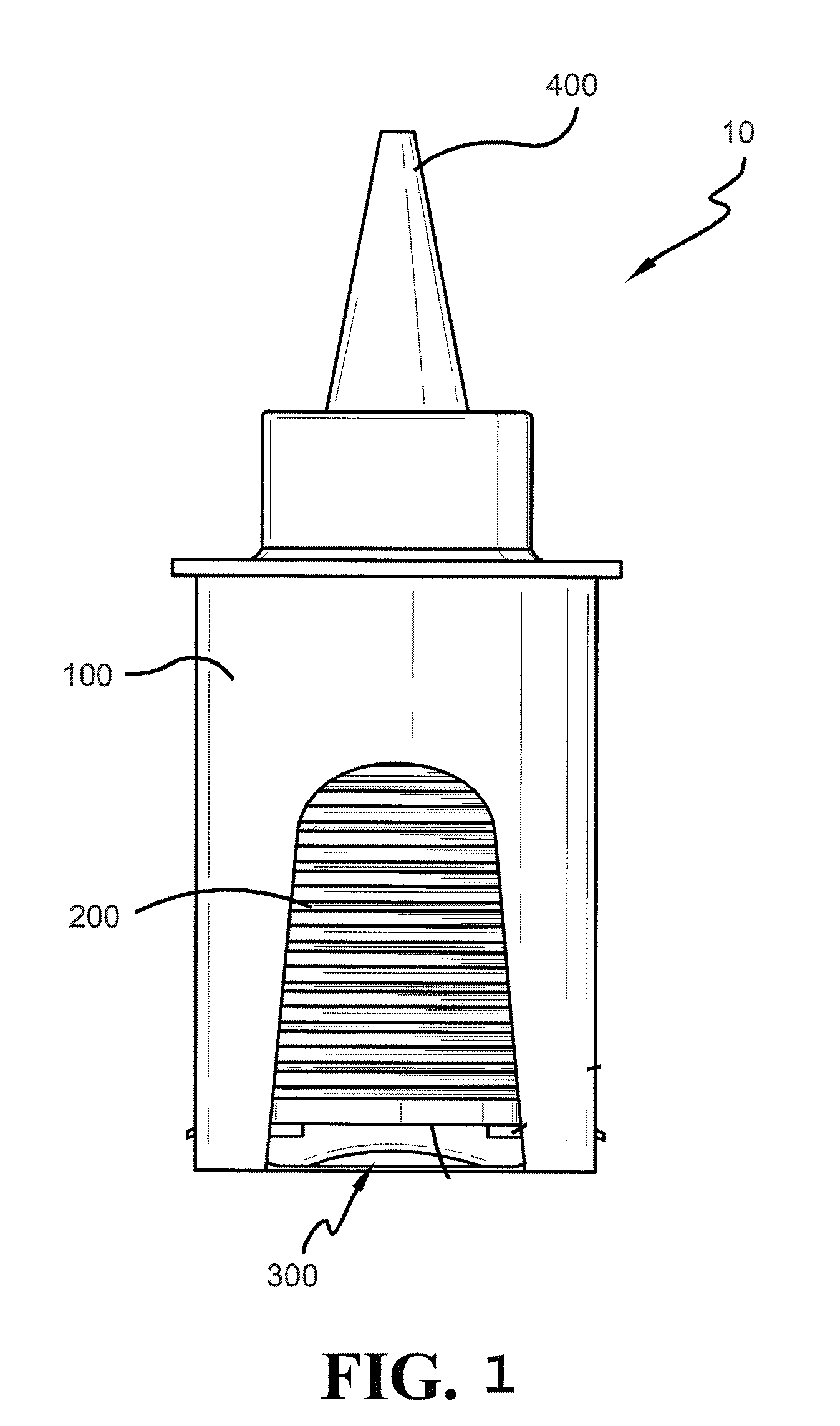

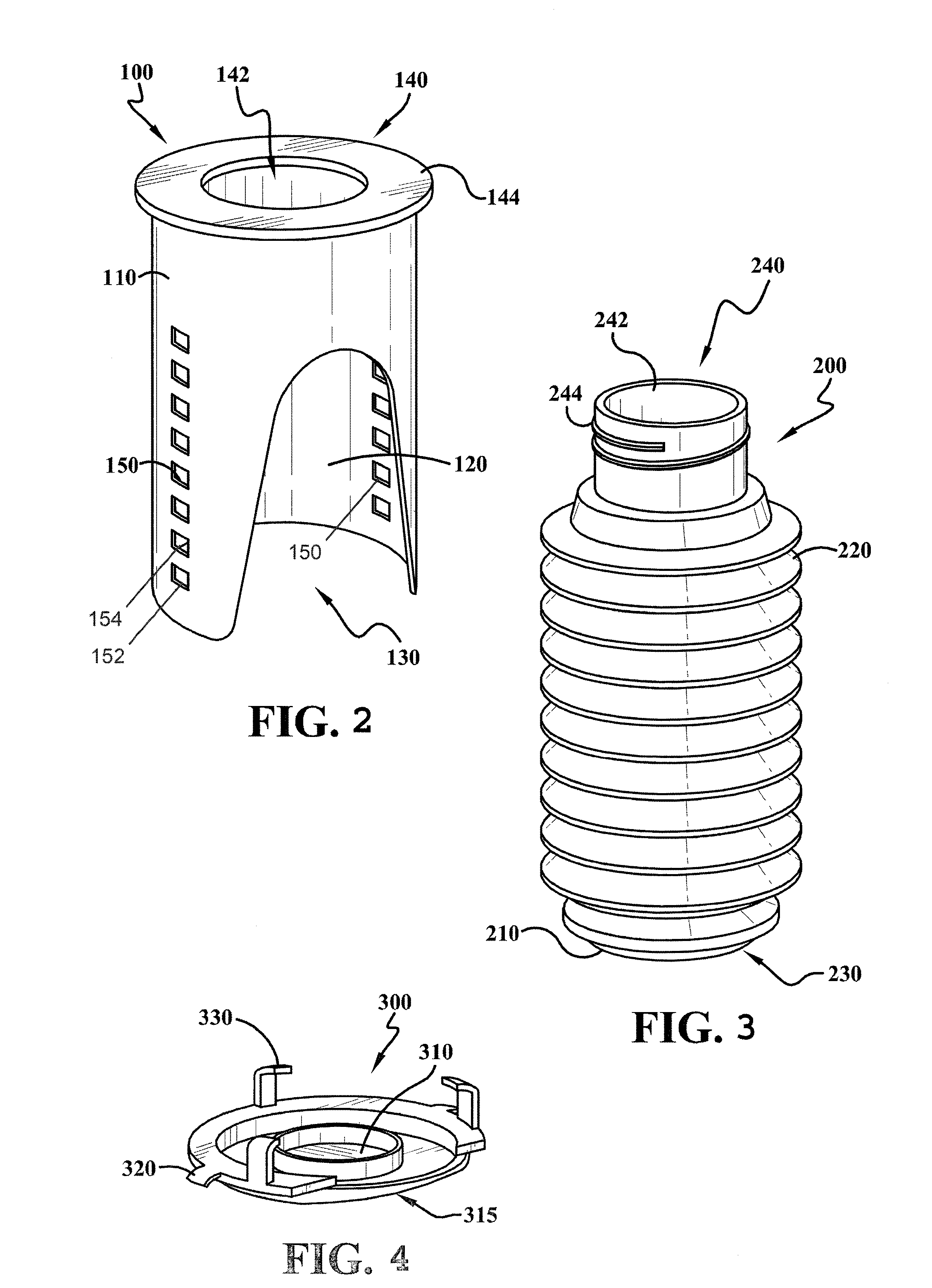

[0035]According to some embodiments, a dispensing device includes a container having a dispensing end and an opposing compression end. The ends are spaced apart and define a longitudinal axis. The container is at least partially enclosed within a housing member. A compression plate is attached to the housing and in contact with the compression end of the container. Applying a compressive force to the compression plate can cause it to move toward the dispensing end, and therefore compress the container and expel fluids contained therein.

[0036]According to some embodiments, a container can include a bottle fabricated from a flexible material, such as an appropriate organic polymer formulation. The dispensing end of the bottle can define an opening for expelling fluids contained therein. In some embodiments, the dispensing end can include an integral nozzle feature, or a means for attaching a nozzle, such as without limitation, threads. The sides of the container define a bellows in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive force | aaaaa | aaaaa |

| internal volume | aaaaa | aaaaa |

| cylindrical shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com