Wet Paint Small Debris Extractor

a technology of extractor and paint, which is applied in the direction of suction cleaners, coatings, pretreated surfaces, etc., to achieve the effect of restricting air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

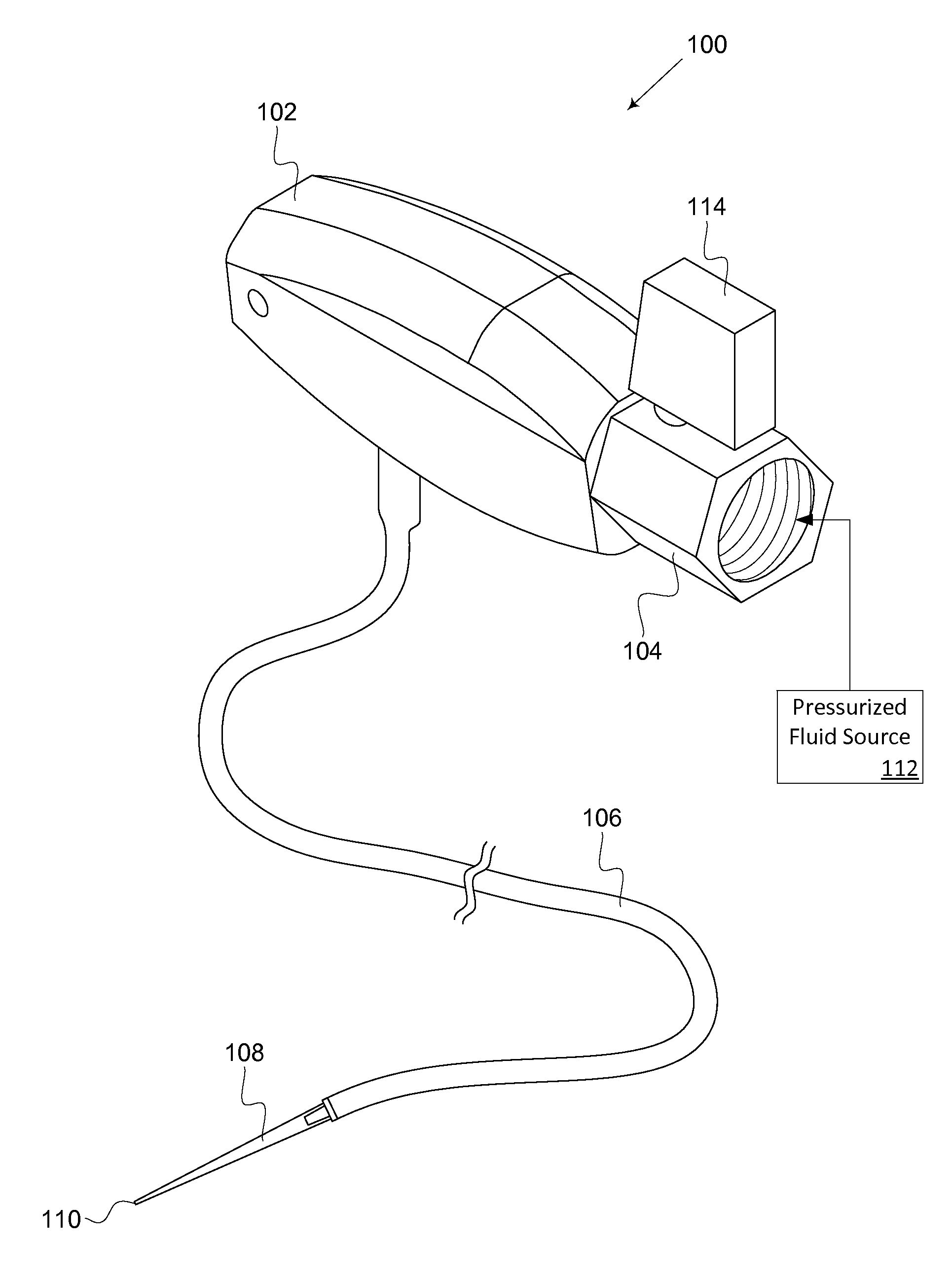

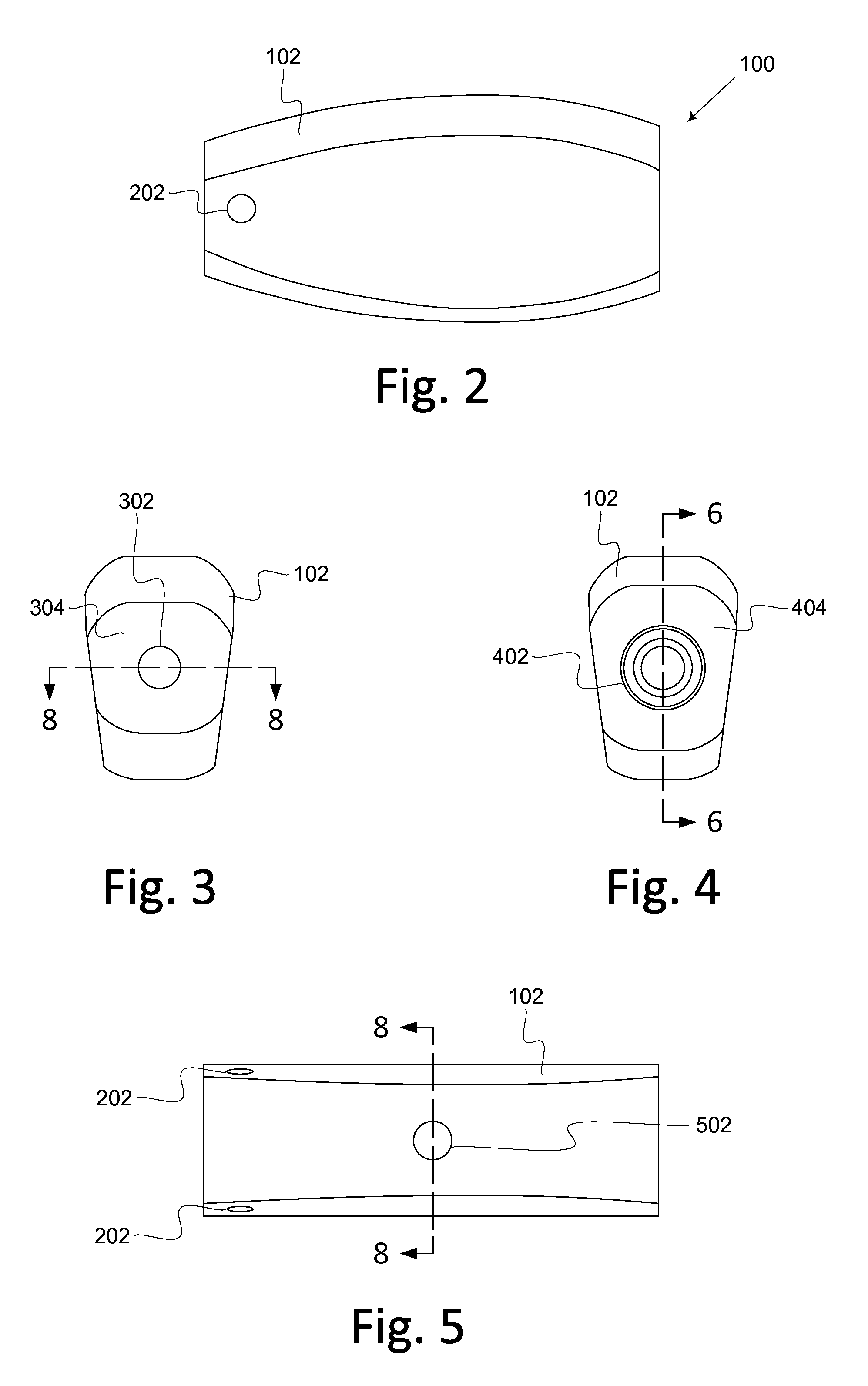

[0016]A small debris extractor for removing debris from wet paint is described herein and illustrated in the accompanying figures. The small debris extractor is an air tool that provides a focused vacuum allowing insects, dust, and other small debris to be removed from wet paint without disrupting the paint finish. The various embodiments of the small debris extractor include an integral pressurized air source or connect to an external pressurized air source. The pressurized air passes through the small debris extractor to create a vacuum in a hose extending from the housing. The vacuum has sufficient suction to extract the small debris from the paint without coming in physical contact with the small debris or the wet paint.

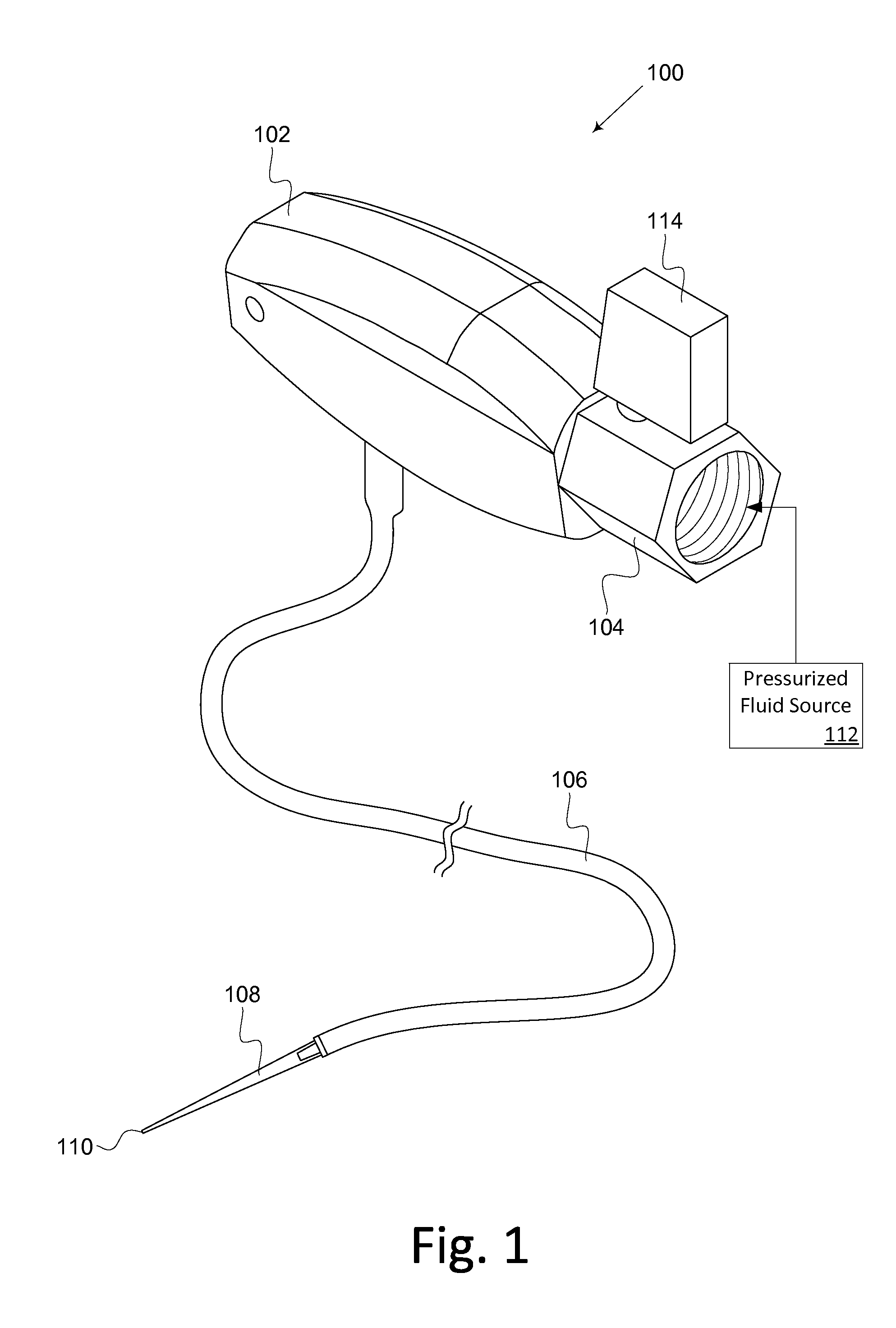

[0017]FIG. 1 is a perspective view of one embodiment of the small debris extractor 100. The small debris extractor includes a housing 102, a valve 104 to control the air flow, a vacuum hose 106, and a replaceable vacuum tip 108. The vacuum tip (i.e., nozzle) atta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com