Pump fluid cylinder including load transfer shoulder and valve seat for same

a technology of fluid cylinder and pump assembly, which is applied in the direction of positive displacement liquid engine, piston pump, liquid fuel engine, etc., can solve the problems of fatigue to failure, high load and frequency of inlet and outlet valves,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

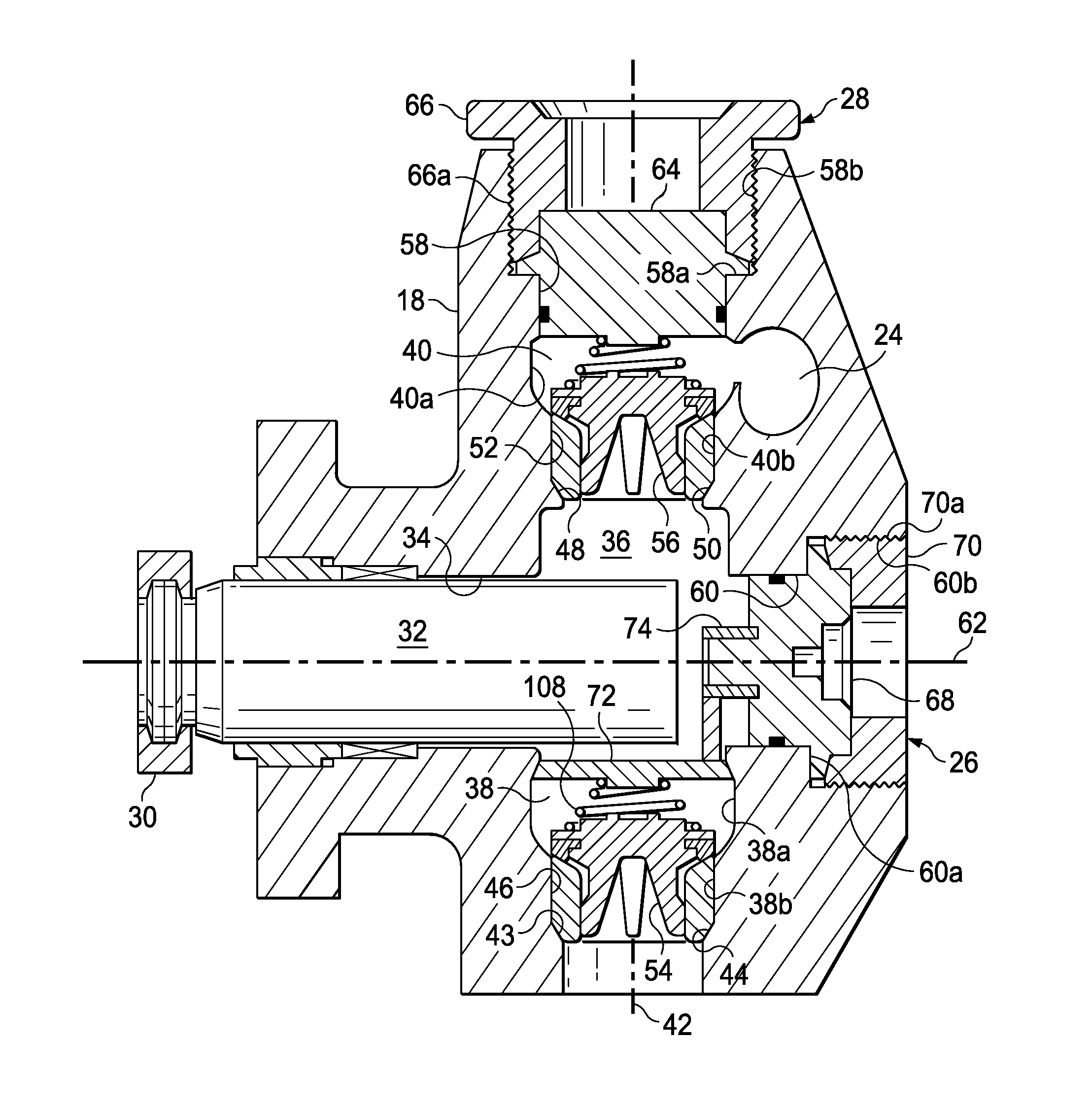

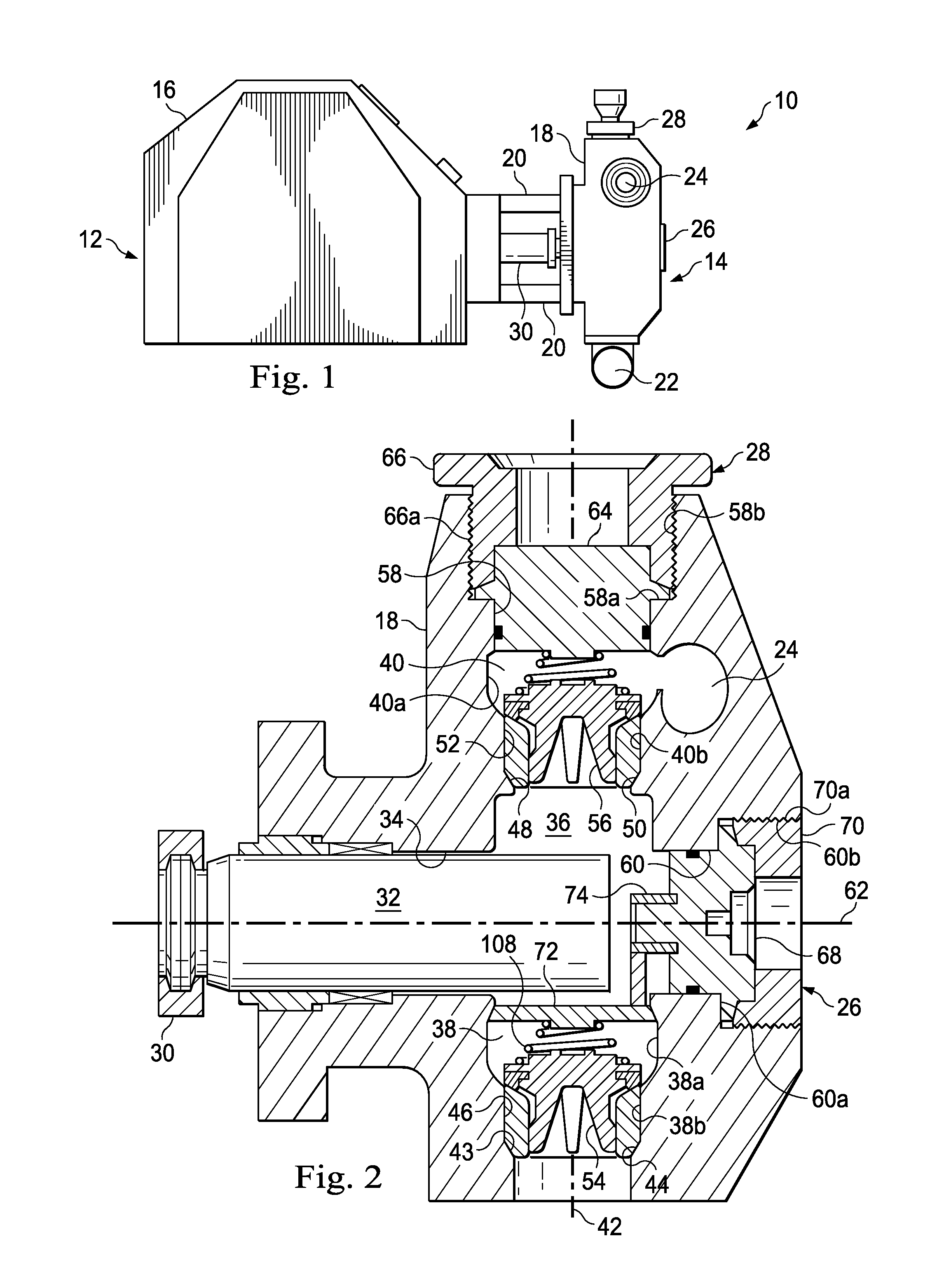

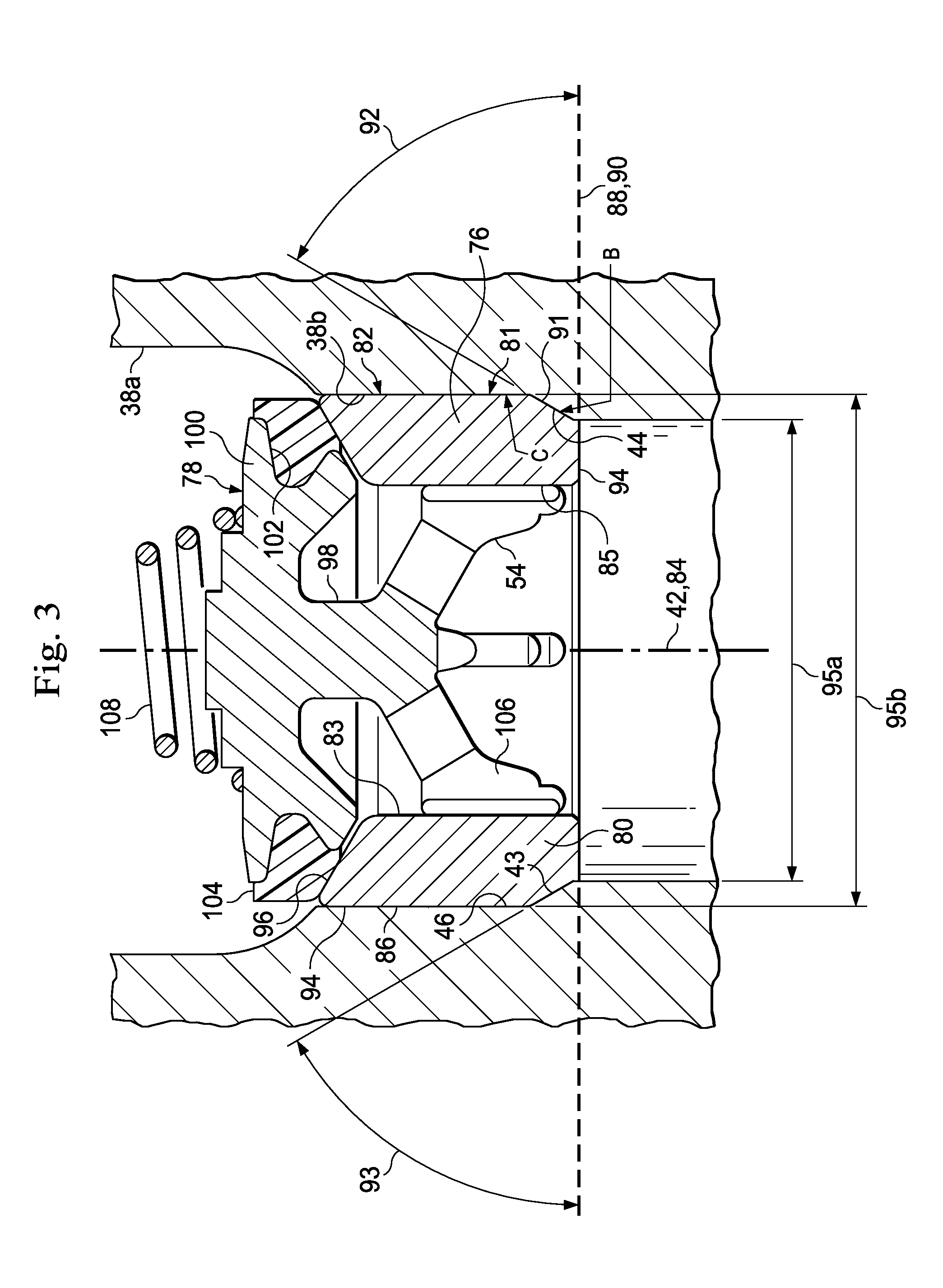

[0032]In an exemplary embodiment, as illustrated in FIG. 1, a reciprocating pump assembly is generally referred to by the reference numeral 10 and includes a power end portion 12 and a fluid end portion 14 operably coupled thereto. The power end portion 12 includes a housing 16 in which a crankshaft (not shown) is disposed, the crankshaft being operably coupled to an engine or motor (not shown), which is adapted to drive the crankshaft. The fluid end portion 14 includes a fluid end block or fluid cylinder 18, which is connected to the housing 16 via a plurality of stay rods 20. The fluid cylinder 18 includes a fluid inlet passage 22 and a fluid outlet passage 24, which are spaced in a parallel relation. A plurality of cover assemblies 26, one of which is shown in FIG. 1, is connected to the fluid cylinder 18 opposite the stay rods 20. A plurality of cover assemblies 28, one of which is shown in FIG. 1, is connected to the fluid cylinder 18 opposite the fluid inlet passage 22. A plun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com