Ballistic Vest with Duty Belt Suspension System

a suspension system and ballistic vest technology, applied in the field of body armor, can solve the problems of cumbersome hips, high energy consumption, and heavy equipment array, and achieve the effects of easy assemblage, low manufacturing cost, and durable construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

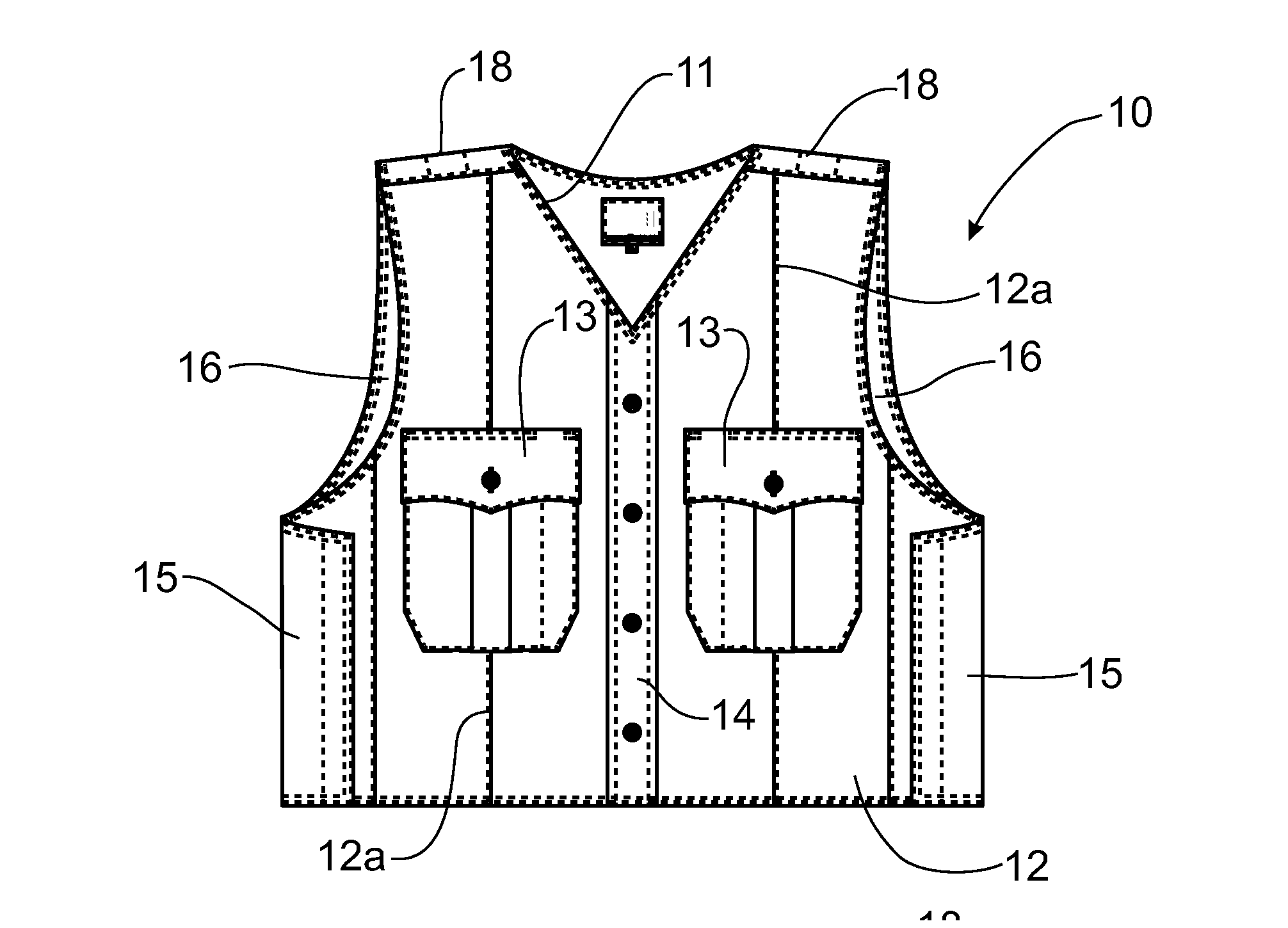

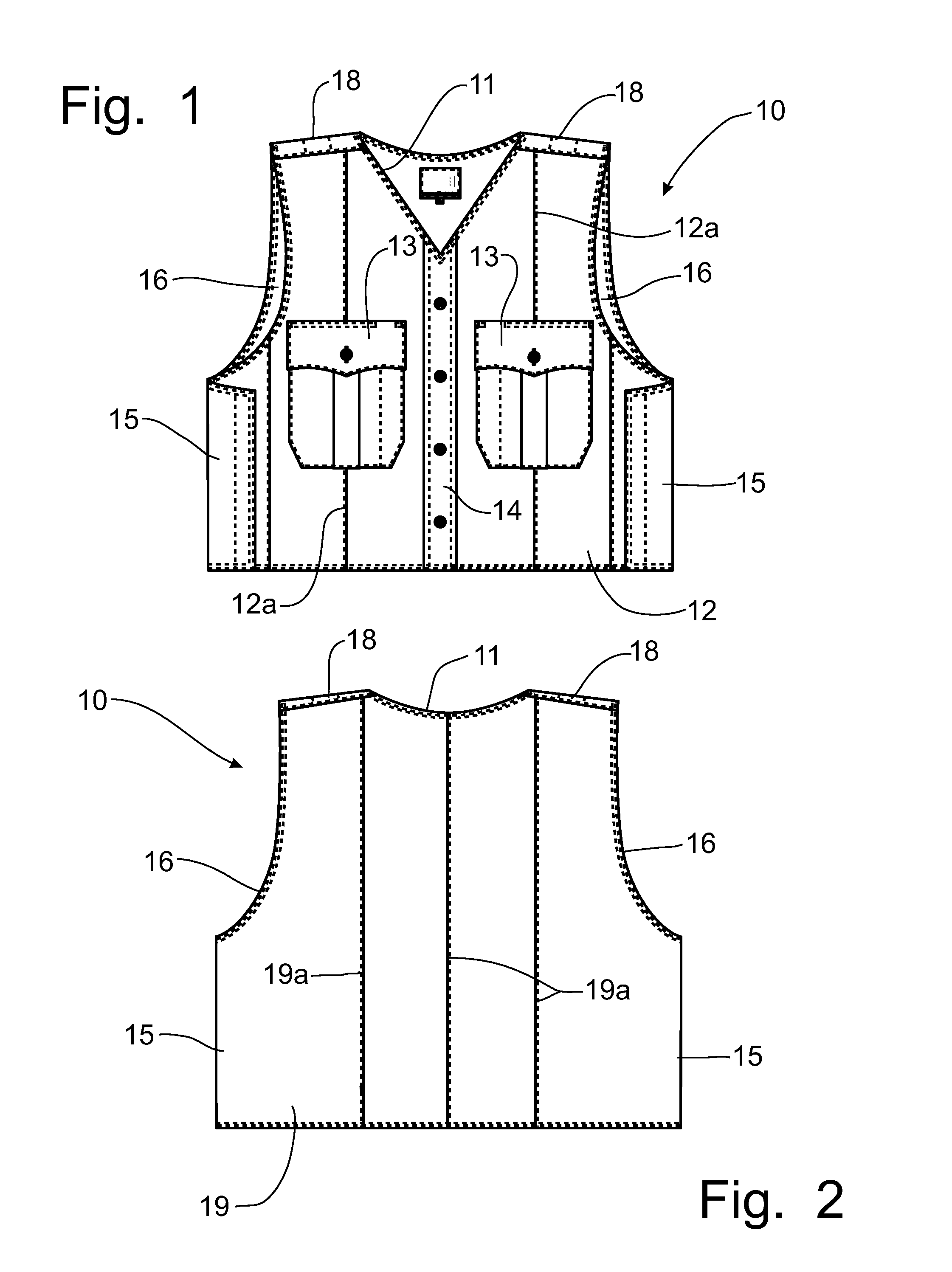

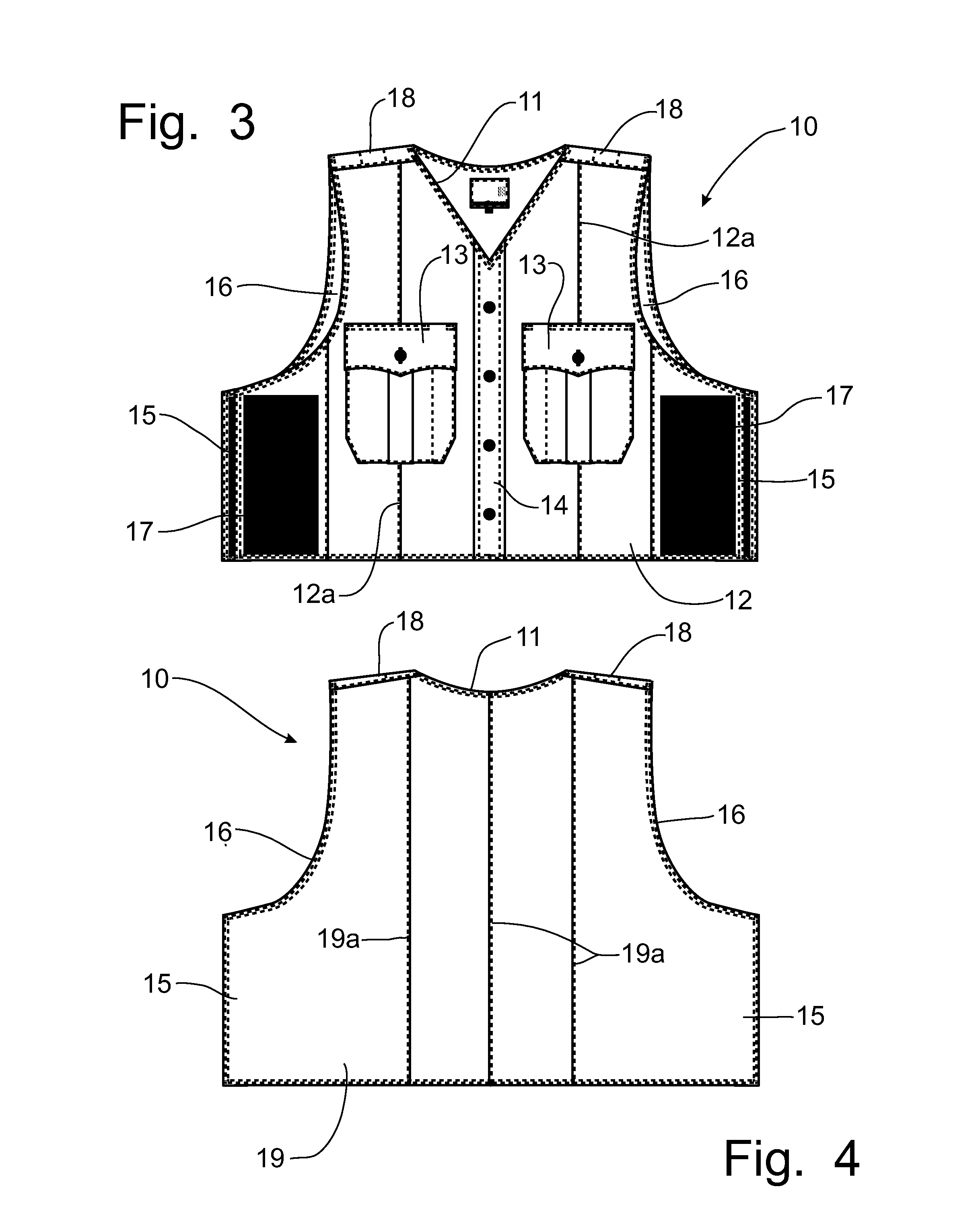

[0060]Referring to FIGS. 1-6A, a bulletproof vest, sometime referred to as body armor, flak vest or a ballistic vest, incorporating the principles of the instant invention can best be seen. The ballistic vest 10 is designed with an opening 11 in the center to allow the vest 10 to be slipped over the head of the person wearing the vest 10 such that there is a front panel 12 lying over the chest of the wearer, as depicted in FIG. 1, and a back panel 19 overlying the back of the wearer, as depicted in FIG. 2. The exterior side of the front panel 12 is configured as an officer's uniform shirt with a pair of functional buttoned shirt pockets 13 and a non-functional buttoned front 14 to simulate a conventional buttoned uniform shirt, even though the ballistic vest 10 is worn by slipping the vest 10 over the wearer's head.

[0061]The sides 15 below the sleeve holes 16 are formed with hook and loop fastener material 17 that can be fastened beneath the wearer's arms once the vest 10 is slipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com