Cooled grinder head

a grinder head and cooling technology, applied in the field of food processing equipment, can solve the problems of increasing the temperature inside the grinder head, slowing down or blocking the grinding operation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

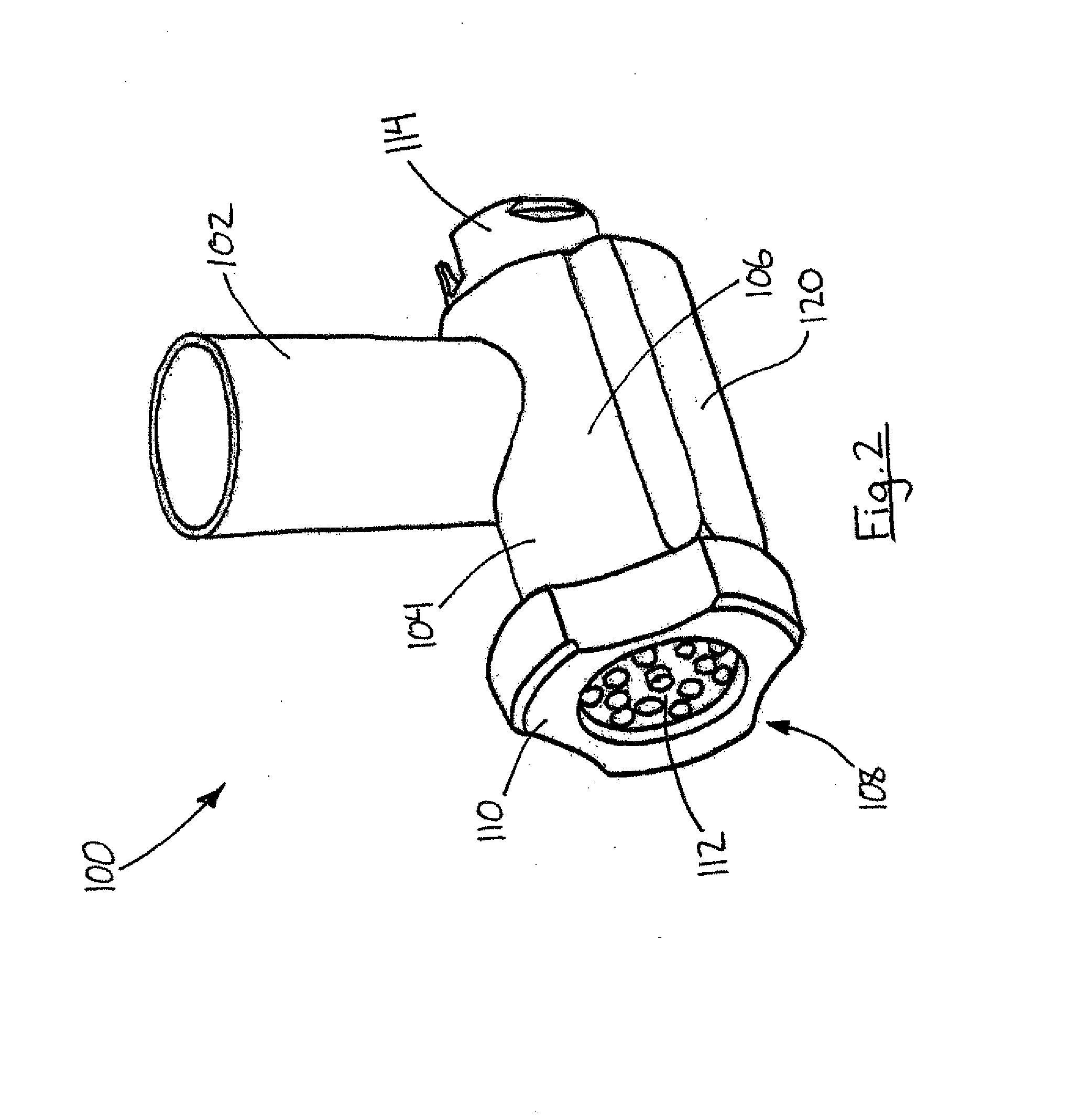

[0017]Referring to FIGS. 2-6, according to the invention, an apparatus 100 in the form of a grinder head includes a portion 102, such as a chute or inlet, for receiving a food product, such as meat (e.g., beef, chicken or pork) or any other food product for which grinding is desired. The grinder head 100 also includes a housing 104 including a grinding portion 106 in which the food product, i.e., meat, is minced or ground to produce a ground meat product. The grinder head 100 further includes an outlet portion 108 through which the ground meat product is discharged.

[0018]The grinder head 100 includes a coupling portion 114 that can be adapted for connection with a typical power unit (not shown in FIGS. 2-6), such as an electric motor (see, e.g., FIG. 1) or a hand crank unit. Operated by the power unit, the components in the grinding portion 106, e.g., the screw conveyor and the knife, rotate to move mix and grind the meat. A threaded collar 110 attached to the grinder housing 104 is...

second embodiment

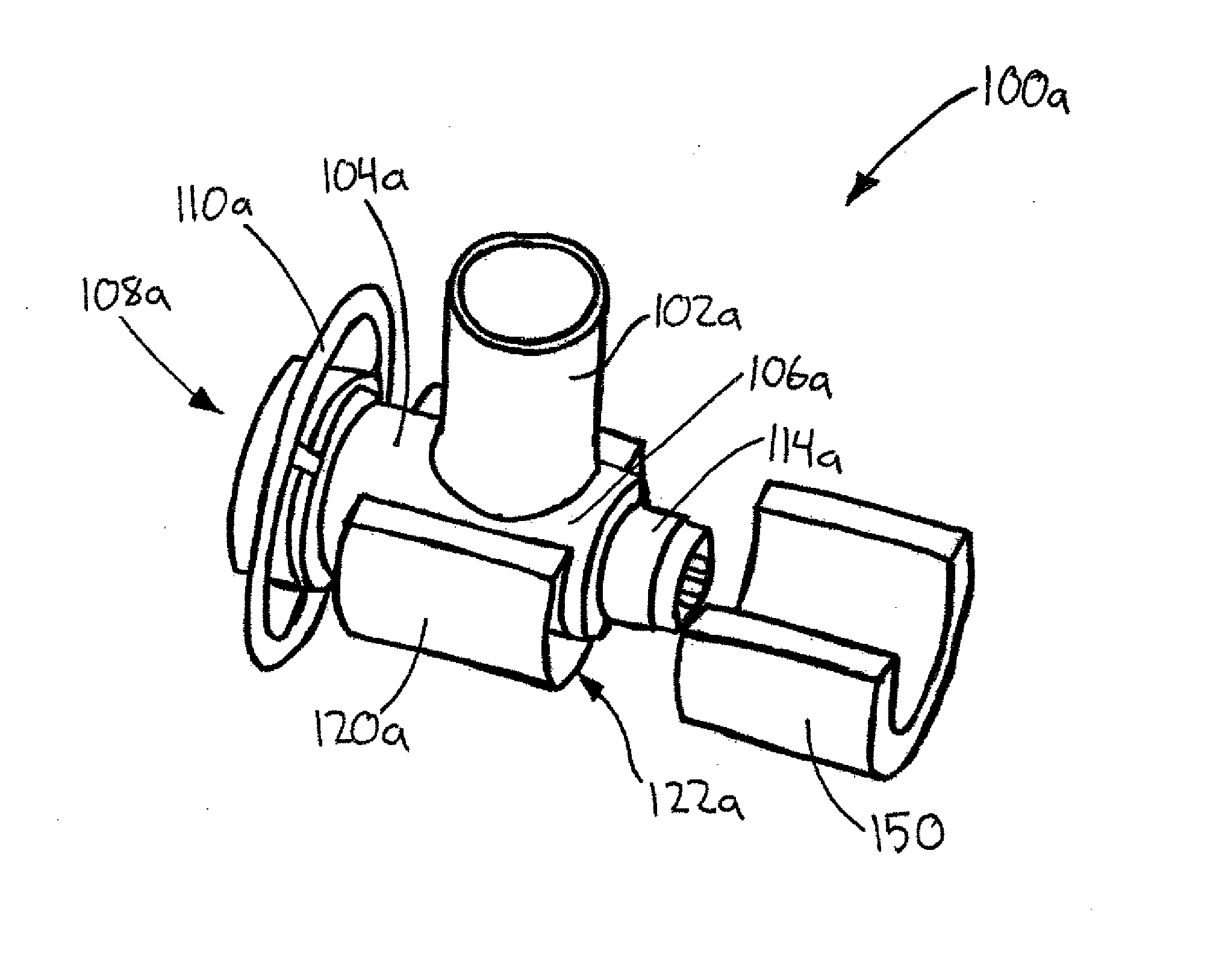

[0025]the invention is illustrated in FIGS. 7-8. The embodiment of FIGS. 7-8 is similar to the embodiment of FIGS. 2-6. Because of this, FIGS. 7-8 utilize reference numbers that correspond to those used in FIGS. 2-6 to identify similar or identical elements. In FIGS. 7-8, these corresponding reference numbers include the suffix “a” in order to avoid confusion.

[0026]Referring to FIGS. 7-8, according to the second embodiment, an apparatus 100a in the form of a grinder head includes a portion 102a, such as a chute or inlet, for receiving a food product, such as meat (e.g., beef, chicken or pork) or any other food product for which grinding is desired. The grinder head 100a also includes a housing 104a including a grinding portion 106a in which the food product, i.e., meat, is minced or ground to produce a ground meat product. The grinder head 100a further includes an outlet portion 108a through which the ground meat product is discharged.

[0027]The grinder head 100a includes a coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com