Drive Pin Assembly

a technology of drive pins and assemblies, applied in the direction of screws, braking discs, ways, etc., can solve the problems of difficult installation, cost, size, complexity, etc., and achieve the effect of effective and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0018]The present invention concerns drive pin assemblies, e.g., of the type that may be used to attach a disc brake rotor to a hub (e.g., for use in an automobile or any other motorized vehicle), as well as to components of such assemblies and methods for using such assemblies and / or components. However, it should be noted that the drive pin assemblies according to the present invention also may be used in any of a variety of other situations.

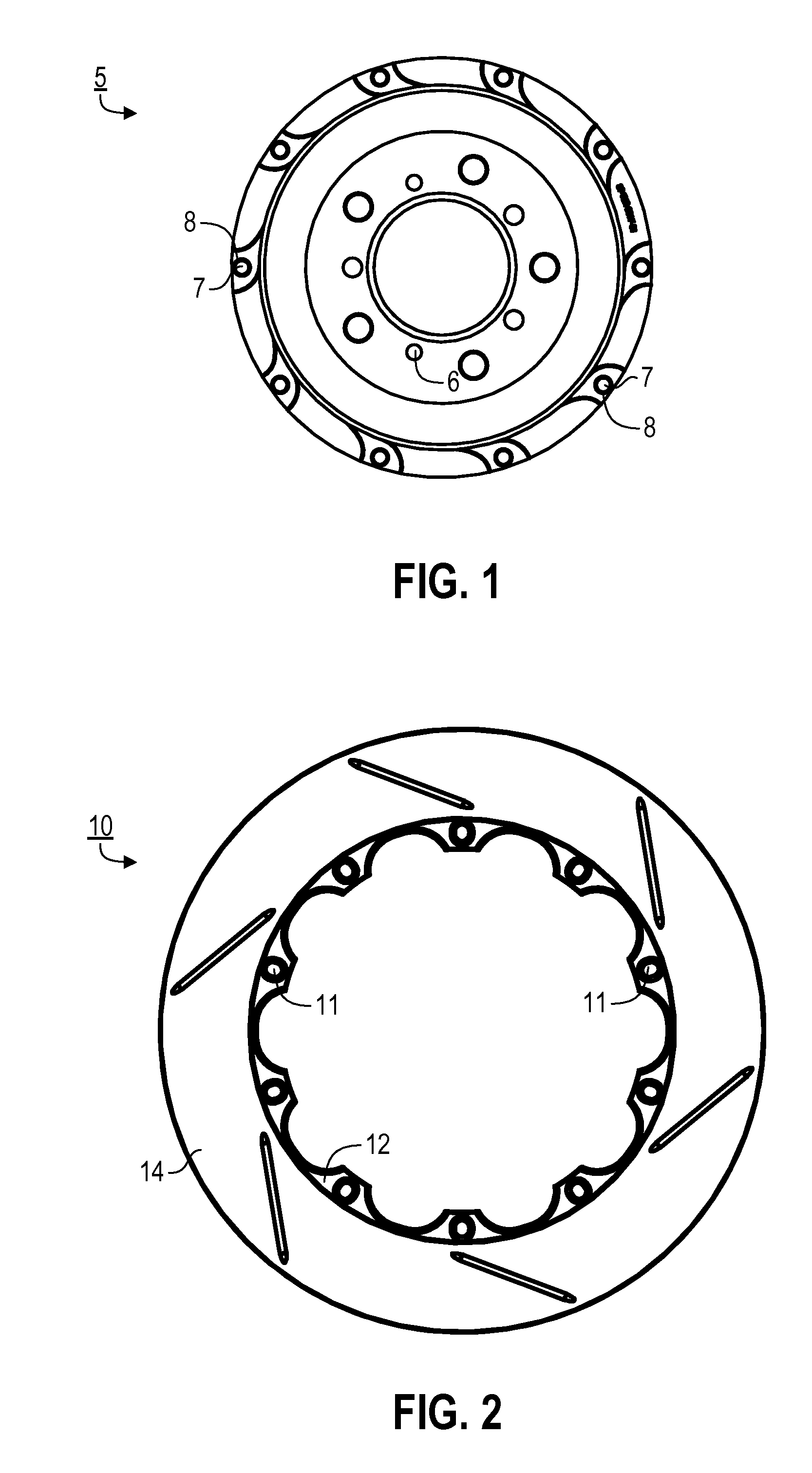

[0019]FIG. 1 illustrates a hub (or hat) 5 that is attached to an axle or a wheel drive assembly of a motorized vehicle (e.g., through openings 6) when in use. One of the purposes of hub 5 is to function as a mounting element for attaching a disc brake rotor. Included in hub 5 is a ring of circular openings (or through-holes) 7, each defined by a sidewall 8, for this purpose.

[0020]FIG. 2 illustrates a disc brake rotor 10 to be attached to hub 5. A ring of openings (or through-holes) 11 are provided within a mounting section 12 (or ring) of rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com