A water purifier fault detection method and circuit

A fault detection circuit and fault detection technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of machines that cannot be automatically detected, poor consumer experience, machine accidents, etc., to achieve easy implementation, effective implementation, accurate high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

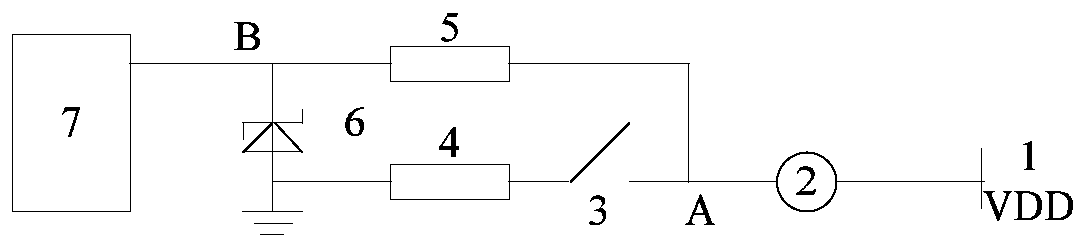

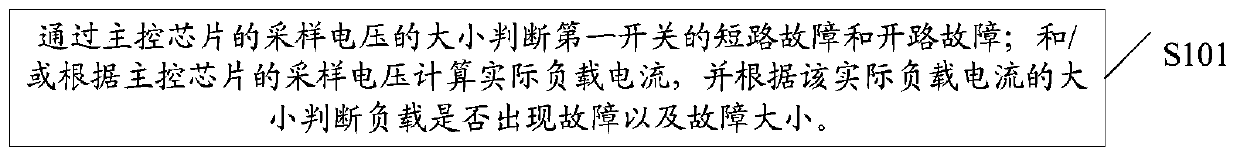

[0057] A water purifier fault detection method, such as figure 1 As shown, the water purifier includes: a system power supply 1, a load 2 and a first switch 3 for controlling the on-off of the load 2, and the fault detection circuit of the water purifier includes: a first resistor 4, a second resistor 5 , a Zener diode 6 and a main control chip 7; wherein, the system power supply 1, the load 2, the first switch 3 and the first resistor 4 are sequentially connected in series and then grounded; the Zener diode 6 is connected in parallel to the voltage sampling terminal of the main control chip 7 and ground between; one end of the second resistor 5 is connected to the voltage sampling end of the main control chip 7, and the other end is connected between the load 2 and the first switch 3; the control output end of the main control chip 7 is connected to the controlled output end of the first switch 3 The main control chip 7 is used to control the on-off of the load 2 by controlli...

Embodiment 2

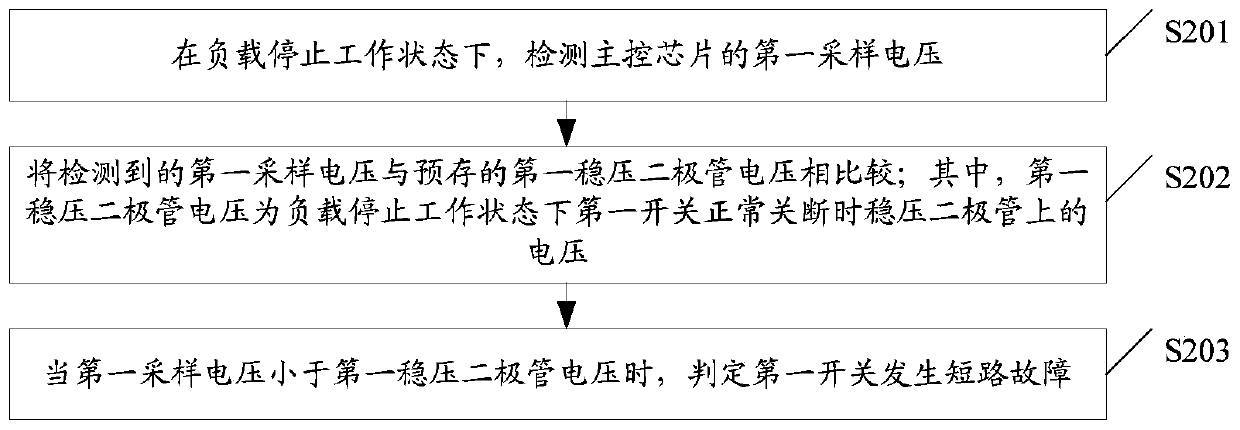

[0062] Based on the first embodiment, this embodiment provides a specific solution embodiment for judging the short-circuit fault and open-circuit fault of the first switch 3 through the magnitude of the sampling voltage of the main control chip 7 .

[0063] Optionally, judging the short-circuit fault and open-circuit fault of the first switch 3 through the magnitude of the sampling voltage of the main control chip 7 may include:

[0064] When the load stops working, judge the short-circuit fault of the first switch by sampling the magnitude of the voltage; and,

[0065] In the load working state, the open circuit fault of the first switch is judged by the magnitude of the sampling voltage.

[0066] In the embodiment of the present invention, when the first switch 3 has a short circuit failure, the water purifier under the load 2 stop working state will be in an abnormal state; when the first switch 3 is open circuit fault, the water purifier under the load 2 working state Th...

Embodiment 3

[0083] On the basis of the first embodiment, this embodiment provides a specific solution embodiment for judging whether the load 2 is faulty and the magnitude of the fault according to the magnitude of the actual load current.

[0084] In the embodiment of the present invention, before the load 2 is fault judged according to the actual load current, the actual load current can be calculated through the voltage collected by the main control chip 7 , that is, the voltage at point B.

[0085] Optionally, calculating the actual load current according to the sampling voltage of the main control chip 7 includes: calculating the actual load current by the following equation:

[0086] I D =U / (R DS +R 1 +R N );

[0087] Among them, I D is the actual load current, U is the sampling voltage, and U is U B , R DS is the internal resistance of the first switch 3, R 1 is the internal resistance of the first resistor 4, R N It is a wire group connecting the connection end of the loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com