Tape Dispenser System

a dispenser and tape technology, applied in the field of tape dispensers, can solve the problems of unnecessarily increasing the cost of manufacture and assembly of these devices, difficulty amplifying, and difficulty, and achieve the effect of efficient and cost-effective system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The following detailed description and appended drawings describe and illustrate an exemplary embodiment of the invention. The description and drawings serve to enable one skilled in the art to make and use the invention, and are not intended to limit the scope of the invention in any manner.

[0022]It should be noted that the terms “outer,”“inner,”“back,”“lower,”“upper” and / or “underside,” as used herein, are meant for reference and / or orientation purposes and are not meant to be limiting in scope.

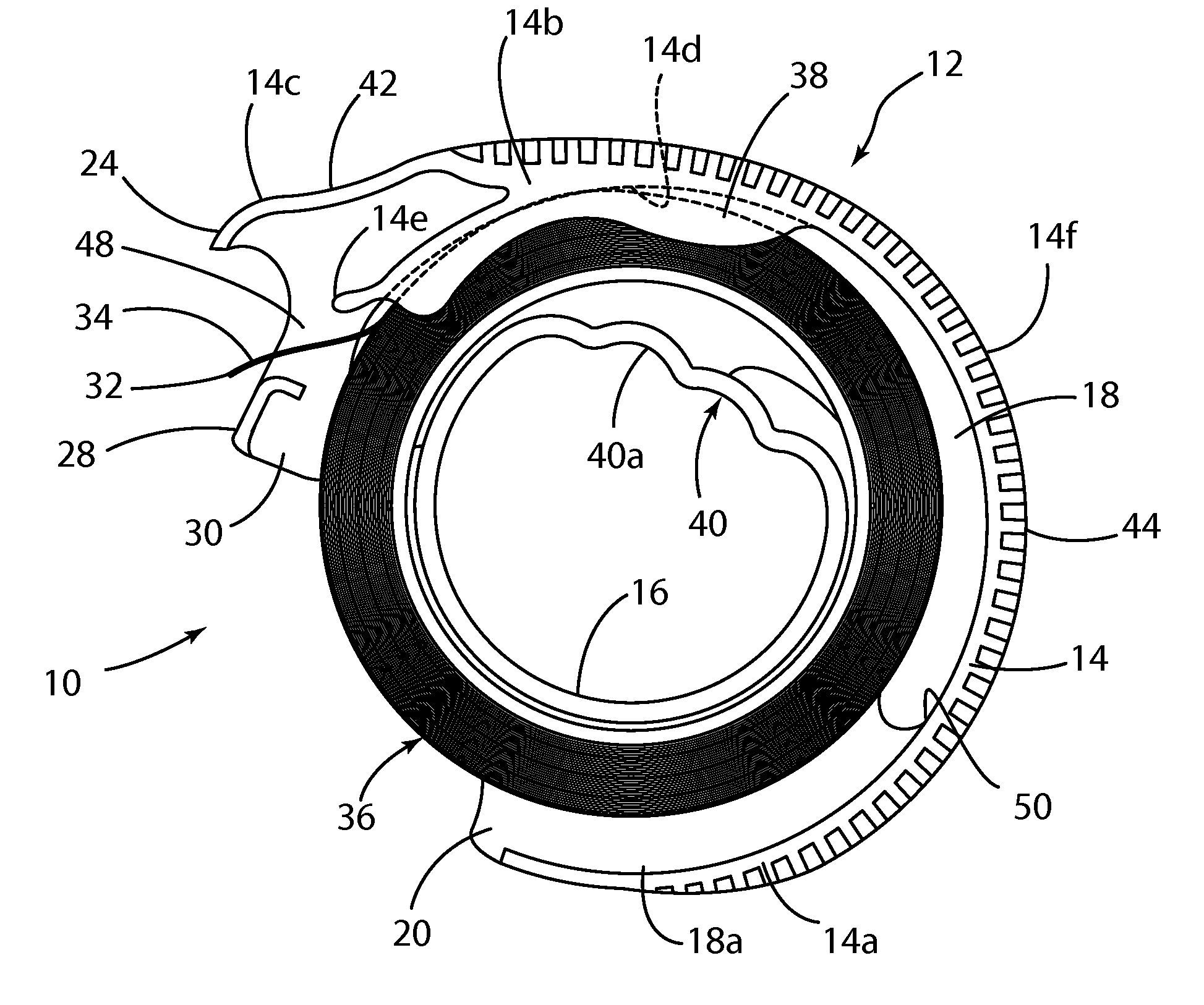

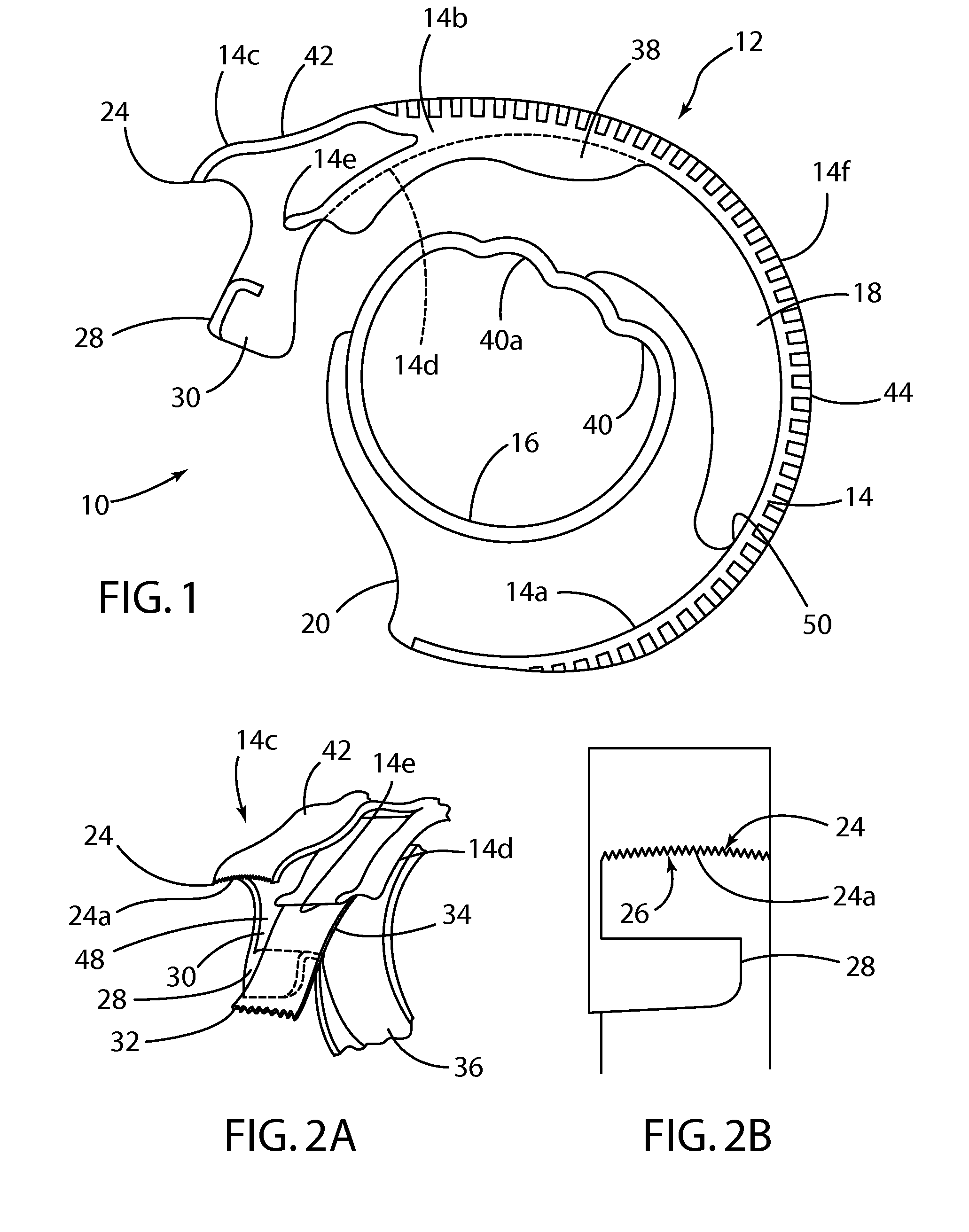

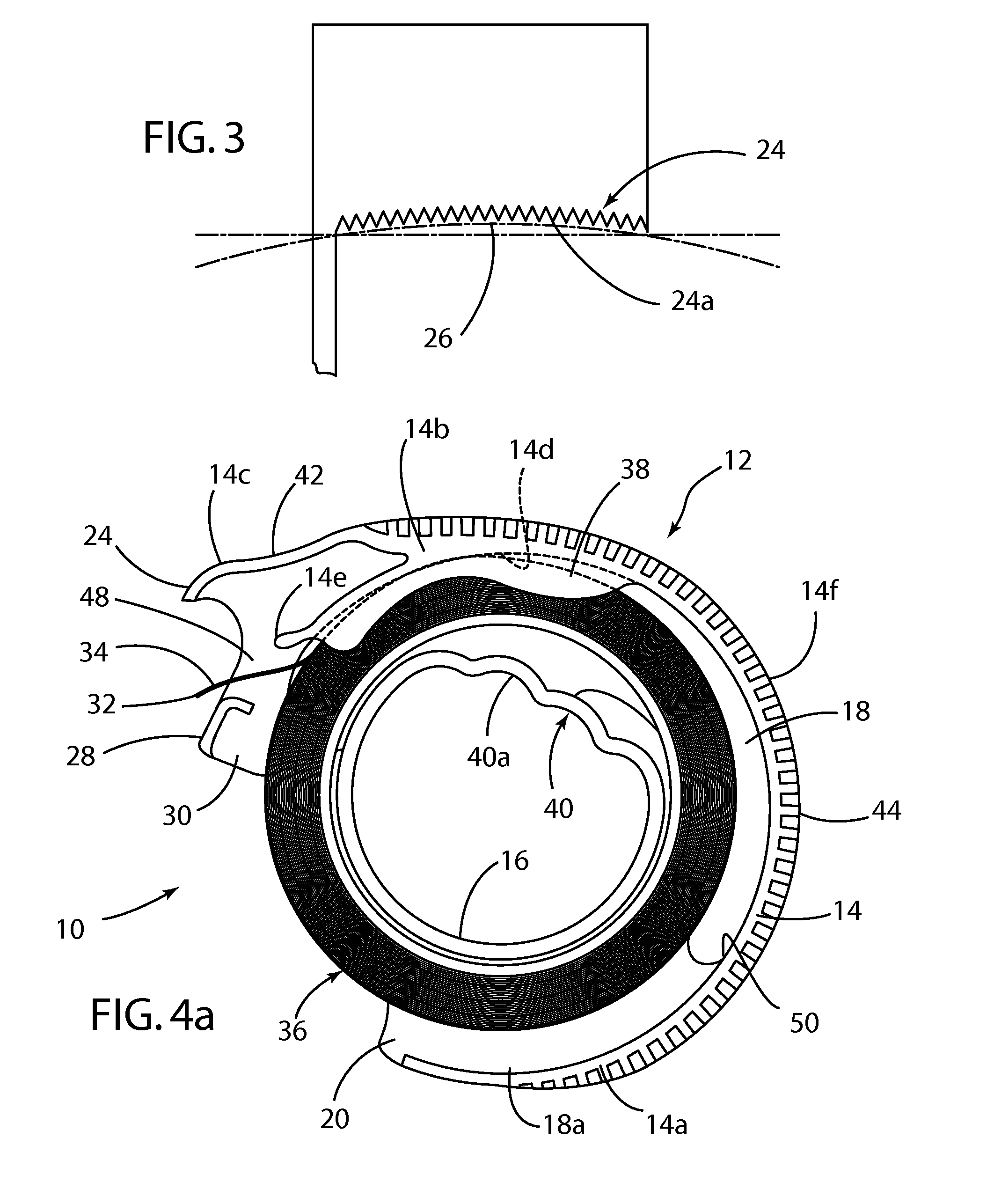

[0023]Referring to the Figures generally, and specifically to FIGS. 1, 4a and 4b, there is illustrated a tape dispenser, shown generally at 10. The dispenser 10 includes a substantially circular or semi-circular body 12 that is preferably formed as a unitary member; i.e., it consists of a single, integrally formed component. The body 12 may be formed of any number of conventional materials; however, plastic materials may be preferred. By way of a non-limiting example, the body 12 may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lineal dimension | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com