Cooling for a fluid flow machine

a fluid flow machine and cooling technology, applied in the field of turbines, can solve the problems of increasing the demands on the materials to be used, affecting the operation of the engine, so as to improve the heat exchange with the surrounding environment, the surface area of the piston-equalizing line is enlarged, and the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

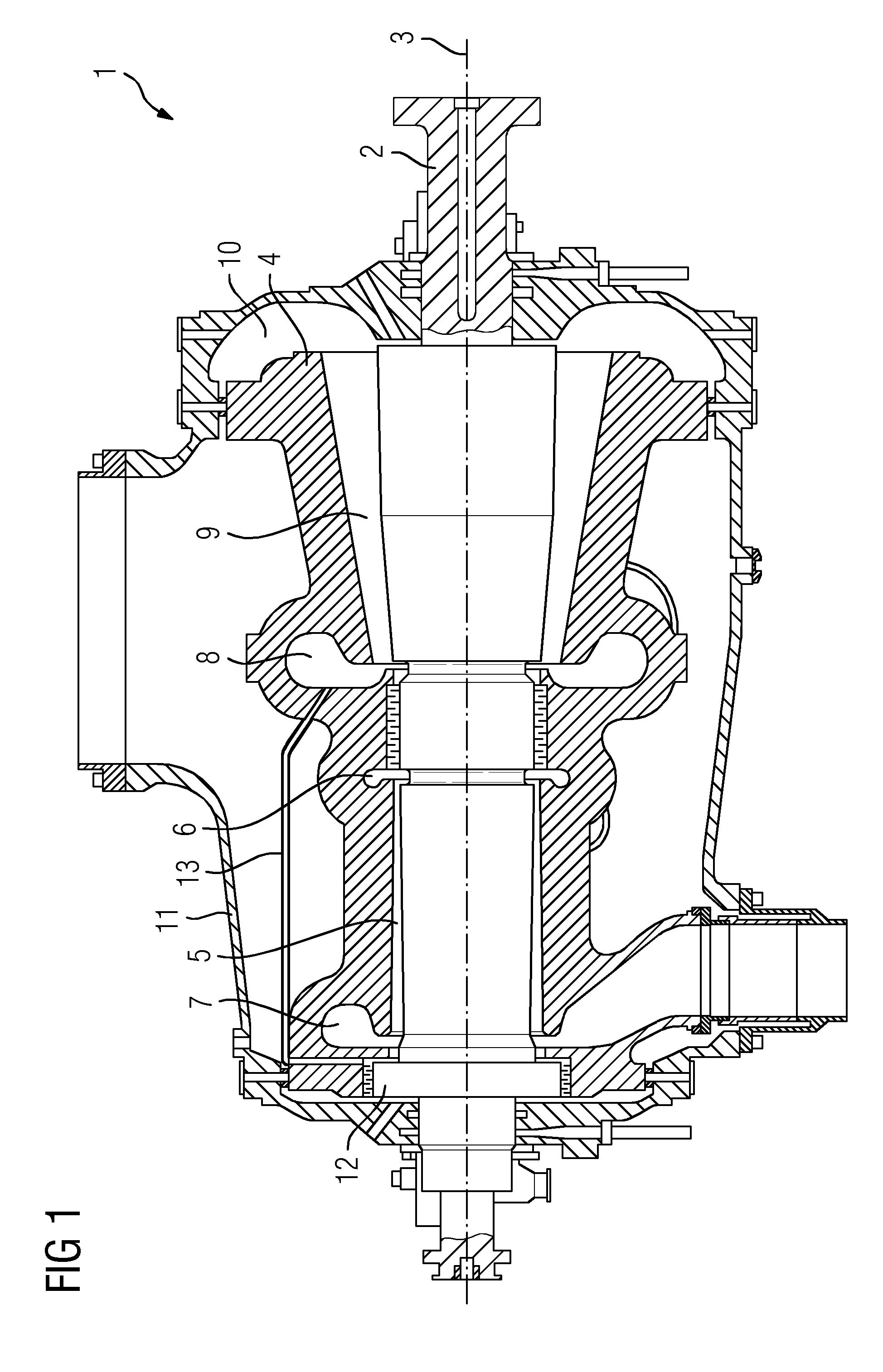

[0017]FIG. 1 shows a steam turbine1 as an embodiment of a turbomachine. The steam turbine 1 comprises, substantially, a rotor 2 rotatably mounted about an axis of rotation 3. An inner housing 4 is arranged about the rotor 2, with a first flow duct 5, which can also be designated as the high-pressure flow region, being formed between the inner housing 4 and the rotor 2. The flow direction of the first flow duct 5 is to the left as shown in the representation according to FIG. 1. In operation, steam flows, via a HP fresh steam region 6, through the inner housing 4 into the first flow duct 5. The steam flowing into the first flow duct 5 via the high-pressure fresh steam region 6 cools down in the flow direction, emerges from the steam turbine 1 via a HP outflow region 7 and, after an intermediate superheater stage, is reintroduced, via an IP inflow region 8 into the steam turbine, to a second flow duct 9. Finally, the steam flows out of the steam turbine 1 via the intermediate-pressure...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap