Modular wire harness arrangements and methods of using same for backside to frontside power and data distribution safety schemes

a module and wire harness technology, applied in the field of roadside and building signage, can solve the problems of insufficient data distribution, time-consuming and laborious, and the retrofitting of non-digital billboards, and achieve the effect of facilitating data distribution and facilitating anchoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109]For reference purposes, whenever the term “frontside” is used it will always refer to the front viewing side of any element or component part that will be described hereinafter. Backside always opposes the frontside for any part or portion being discussed and is the reverse of the viewing side. Each surface is defined hereinafter in the following manner as a part frontside / backside.

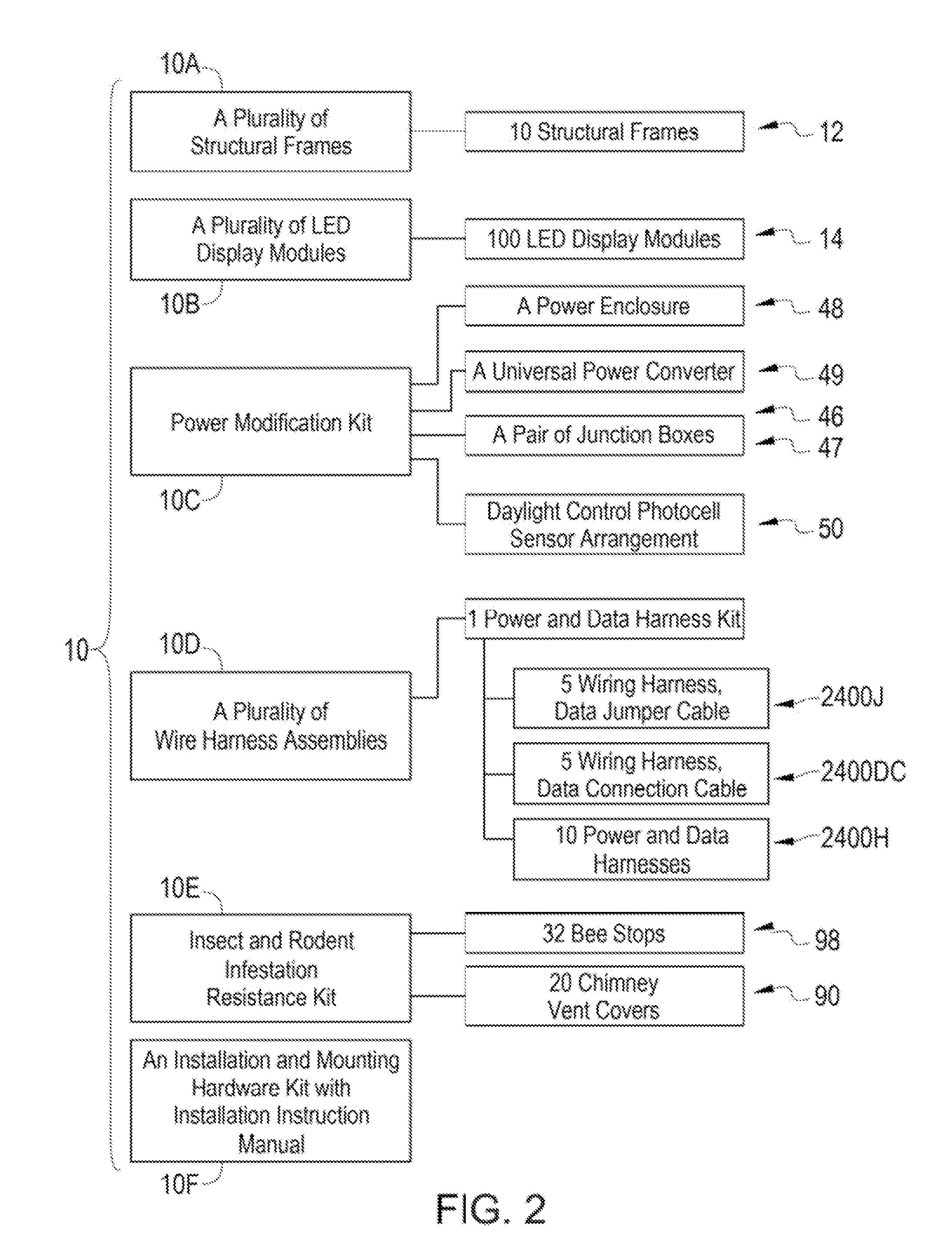

[0110]Referring now to the drawings and more particularly to FIGS. 1 and 2, there is illustrated a self contained retrofit kit 10 and a resulting dynamic electronic sign or billboard 110 respectively, which kit 10 and which billboard 110 are each constructed in accordance with the present invention. The electronic billboard 110, when constructed in accordance with a novel method of retrofitting or assembling 1010 (FIG. 19) as hereinafter disclosed, is assembled in a fast and convenient manner without the need of special tools or equipment. In short, by use of the in field retrofit kit 10, a static n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com