Electronic cigarette connection base and electronic cigarette atomization device

a technology of electronic cigarettes and connection bases, which is applied in the direction of tobacco pipes, tobacco, food science, etc., can solve the problems of low production efficiency of electronic cigarettes and bad sealing effect of electronic cigarettes, and achieve high product rate, good sealing effect, and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

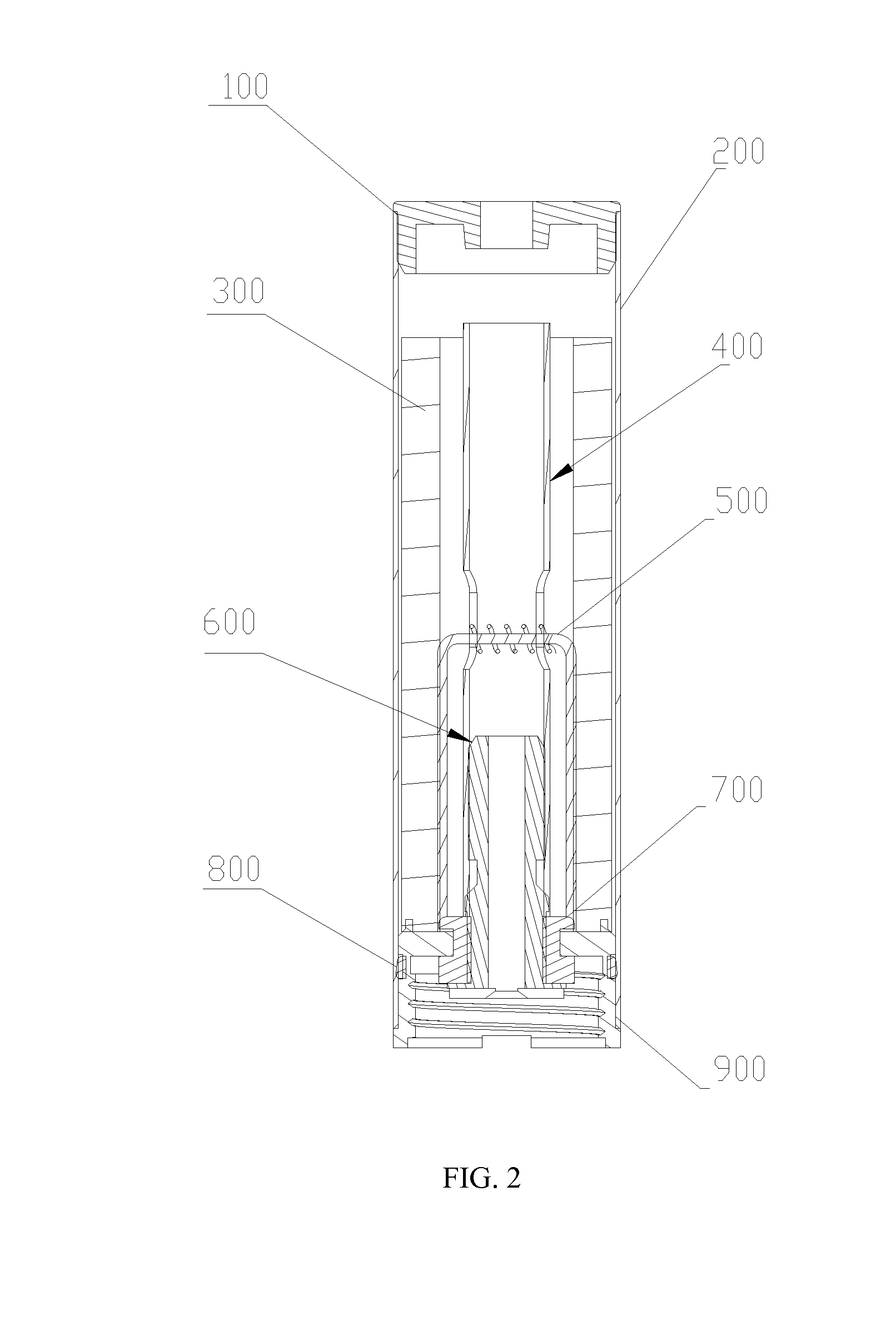

[0038]FIGS. 4-6 illustrate the present invention. Wherein, a connection base 900 comprises a top cover 903, a side wall 902 is formed around an edge of the top cover 903; the side wall 902 defines a filling groove around an outer surface of the side wall 902; and the filling groove 901 is filled with seal filler, for example, adhesive, such as different kinds of suitable glue. After filled with glue, the connection base 900 is embedded from the bottom of an atomization outer sleeve 200, and the outside of the side wall 902 of the connection base 900 is in tight contact with the atomization outer sleeve 200. In order to make the connection base 900 be in tight contact with the atomization outer sleeve 200, diameters of the connection base 900 and the atomization outer sleeve 200 should match with each other, and a complete electronic cigarette atomization device is formed in the way of interference fit or engagement. Additionally, the connection base 900 is chamfered, so that the con...

second embodiment

[0041]In the present invention, the filling groove 901 of the connection base 900 may be in other shapes. For example, in the present invention as shown in FIG. 7, the filling groove 901 includes straight line grooves which are perpendicular to the top cover (i.e., positioned along an axial direction of the periphery surface of the side wall of the connection base). Every two adjacent ones of these straight line grooves are parallel to each other and are separated with a certain distance. When the filling groove 901 is filled with glue and replaces the connection base 900 shown in FIG. 4 and FIG. 6, the sealing for the oil storage cotton 300 can also be achieve.

[0042]Two kinds of the filling grooves mentioned above have different advantages: in the first embodiment, the annular filling groove is corresponding to the inner wall of the whole atomization outer sleeve 200, therefore, the sealing effect is better; in the second embodiment, the longitudinal straight line filling groove ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com