Mechanism for collecting impurities in stagnant waters

a technology of impurities and machines, applied in water cleaning, special purpose vessels, separation processes, etc., can solve the problems of insufficient equipment for collecting impurities from water surface, inefficient use, and high cost of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

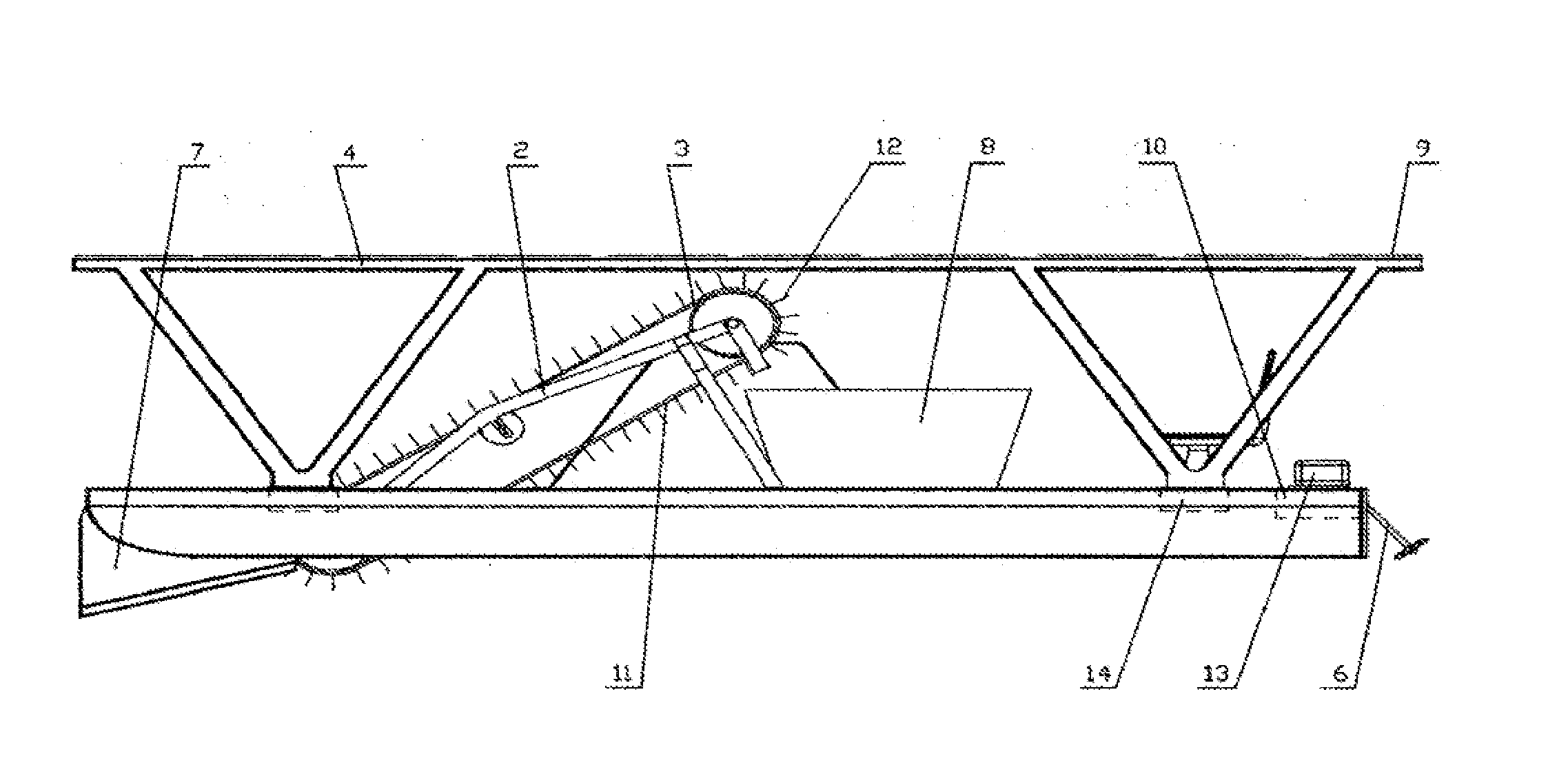

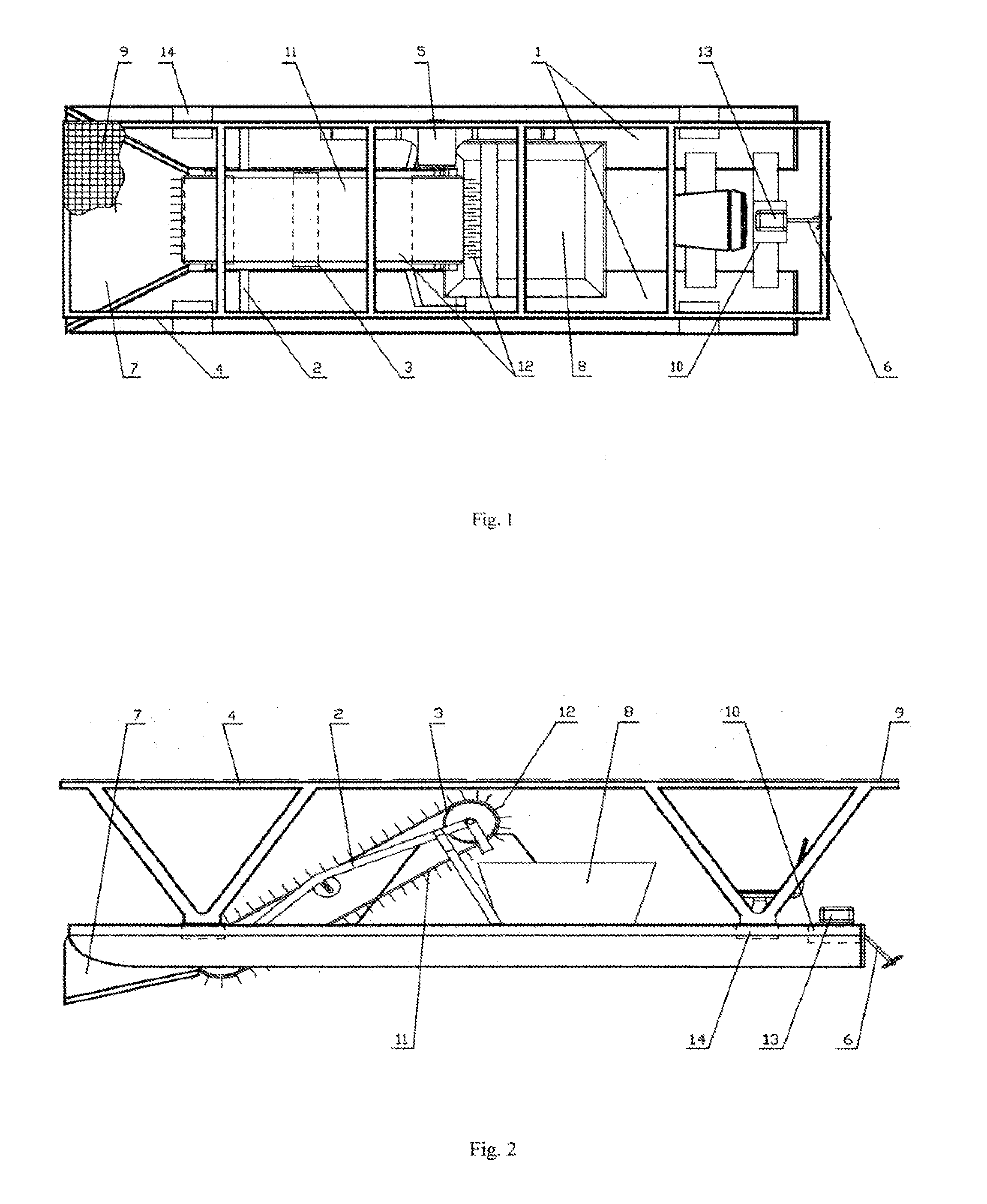

[0011]The equipment for collecting impurities in stagnant waters comprises two catamaran floats 1, having a shape of a hollow body, for example a shape of a semi-cylinder. At the front of the catamaran floats 1, there is a drum belt conveyor 3, mounted in the frame 2. The belt conveyor 3 can include a removable, perforated mesh belt 11, made of felt, textile, or plastic material or of metal, fitted with forks 12 for collecting solid and viscous impurities from the water. The impurities are gathered through the frontal funnel-shaped part—jaws 7, by the belt 11 into the removable container 8. The drive 5 of the belt 11 is an electric motor mounted at the axis of the driving drum of the belt conveyor 3. In the middle part of the catamaran floats 1 there is the drive 5 of the belt 11, connected to the batteries 14, in the rear part of the equipment there is the rudder 6 and the marine engine 13, the whole with manual control or with programmable remote control 10. At the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Speed | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com