Hair pin

a technology of hairpins and clips, applied in the field of hairpins, can solve the problems of not having a composite function of strong hairpins with a further difficulty in holding a lot of hairs, and the clipping portion does not hold the hairs effectively, so as to improve the utility of the clipping portion, improve the marketability, and effectively press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]A hairpin according to an embodiment of the present invention will be hereafter described in detail with reference to the accompanying drawings.

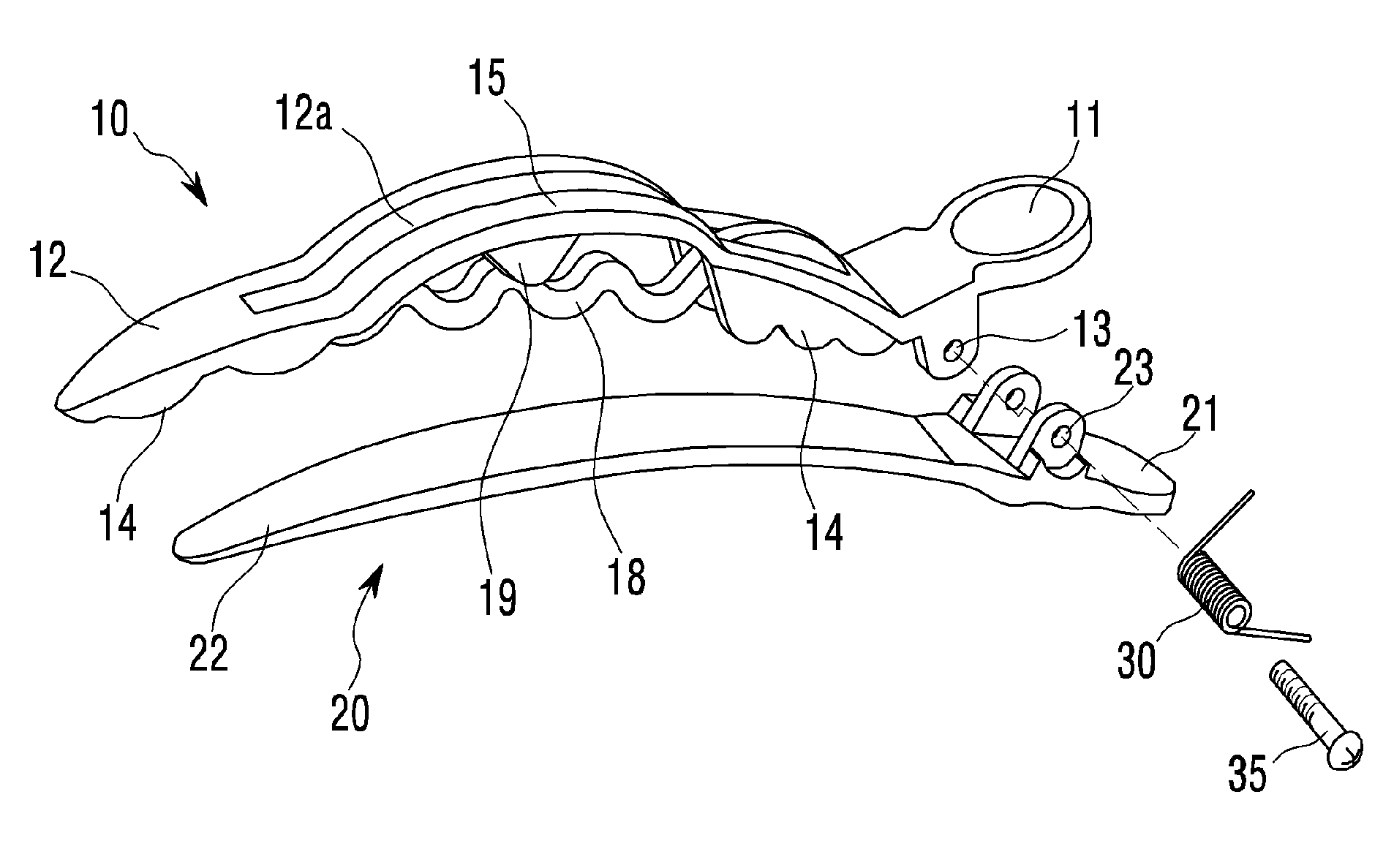

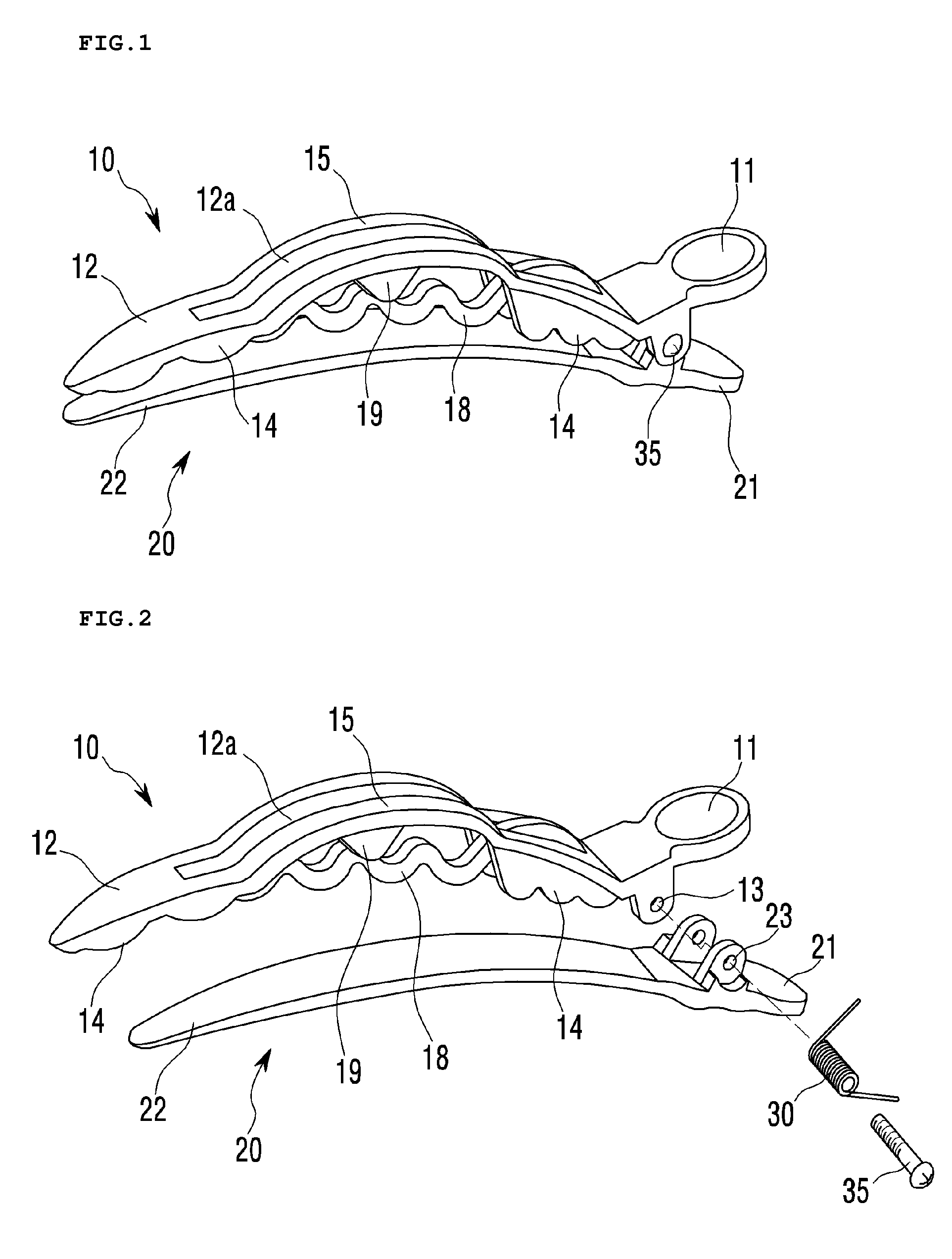

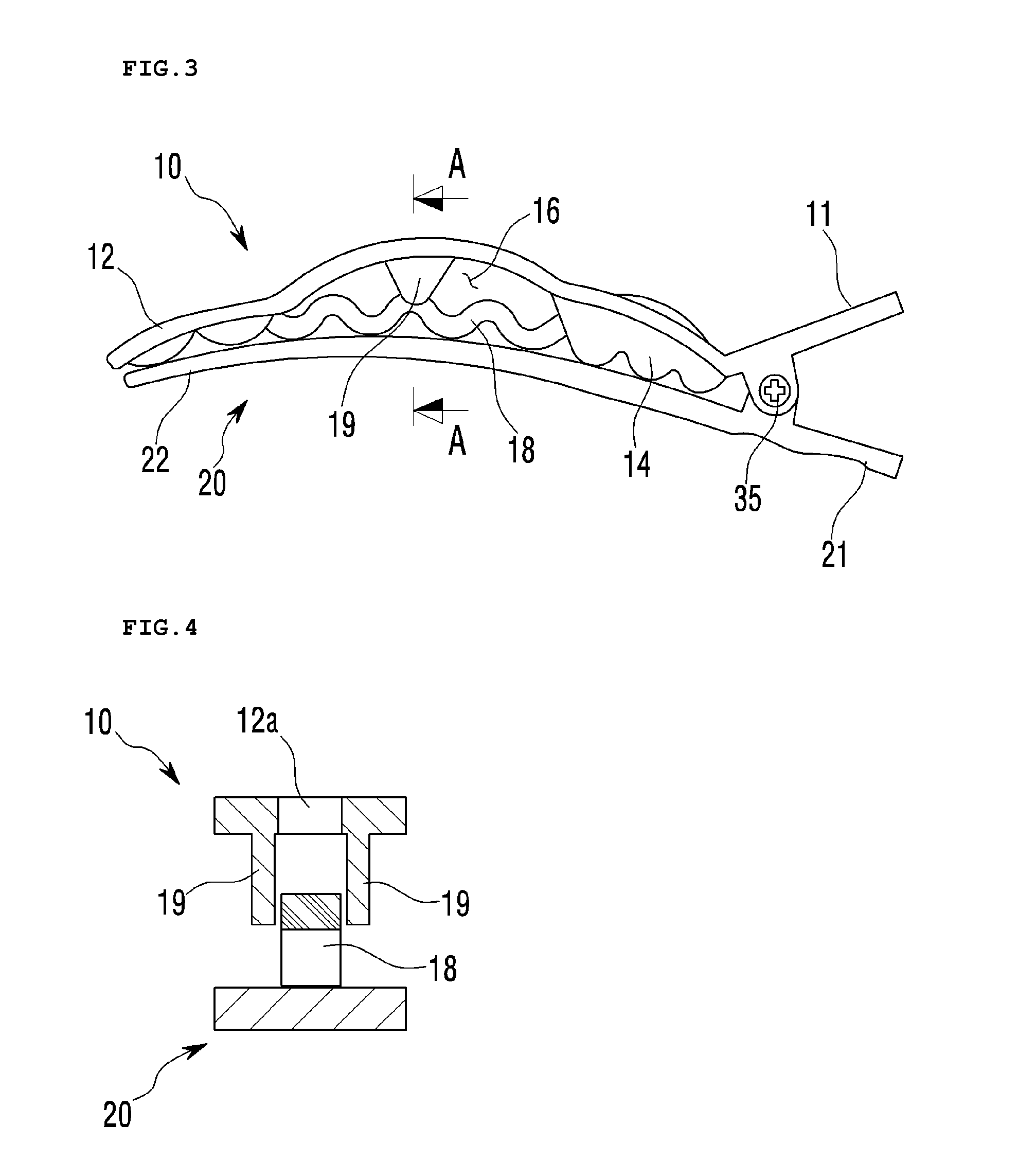

[0040]The hairpin of the present invention includes, as illustrated in FIGS. 1 to 5, upper and lower clips 10 and 20 having finger pressing portions 11 and 21 and clipping portions 12 and 22, a hinge shaft 35 that is inserted in holes 13 and 23 formed in the upper and lower clips 10 and 20, and a torsion spring 30 through which the hinge shaft 35 passes, in order to hold hairs in place by tension force of the clipping portions 12 and 22 of the upper and lower clips.

[0041]In particular, the clipping portion 12 of the upper clip 10 has a convex holding portion 15 protruding outwardly from an inner center of the clipping portion to form a space 16 for retaining the hairs therein, and a resiliently pressing portion 18 integrally extending from the clipping portion below the convex holding portion 15 in a longitudinal direction of the clipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com