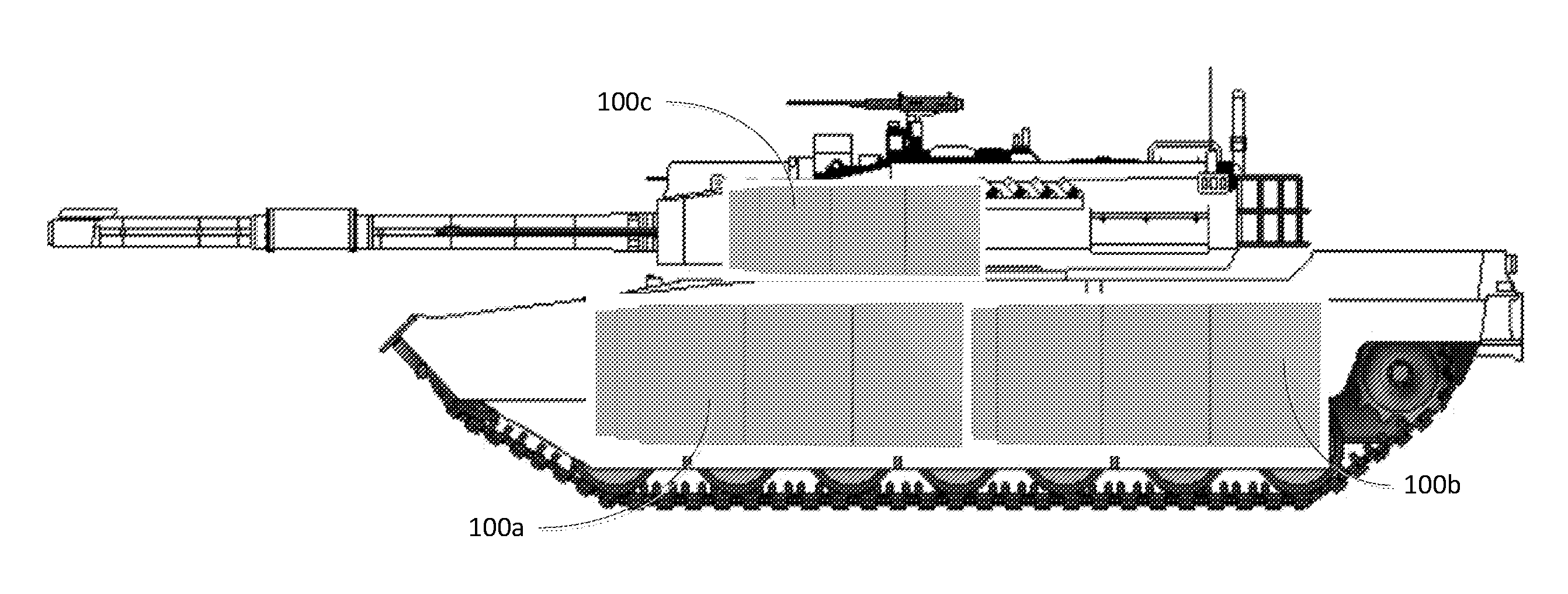

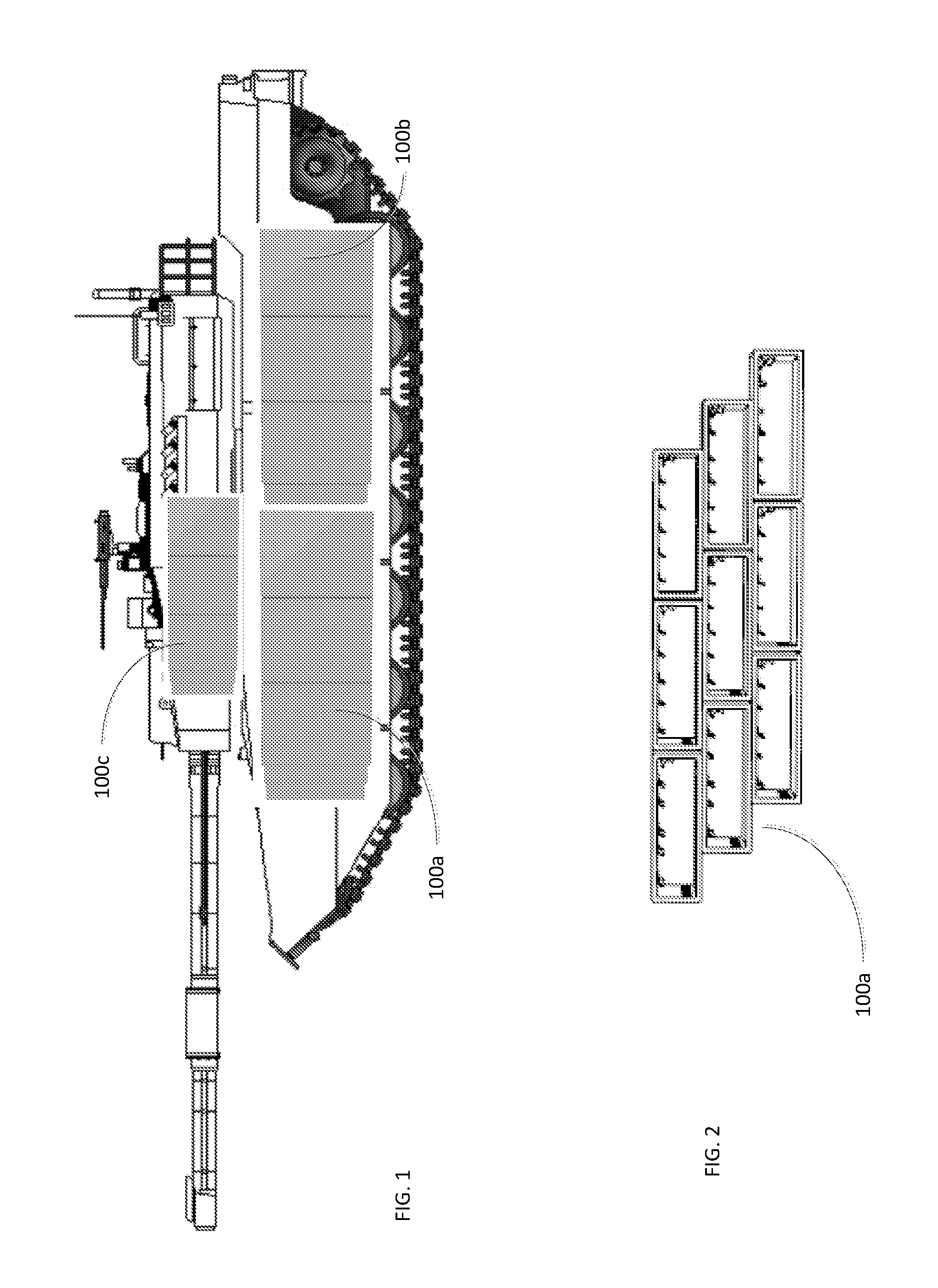

Armor

a technology of armor and assembly, applied in the field of armor units and assembly construction, can solve the problems of poor defeat of efp or hybrid systems by explosive systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]Additional objects and advantages of the invention will be set forth in part in the description which follows, and in part will be obvious from the description, or may be learned by practice of the invention. The objects and advantages of the invention will be realized and attained by means of the elements and combinations particularly pointed out in the appended claims.

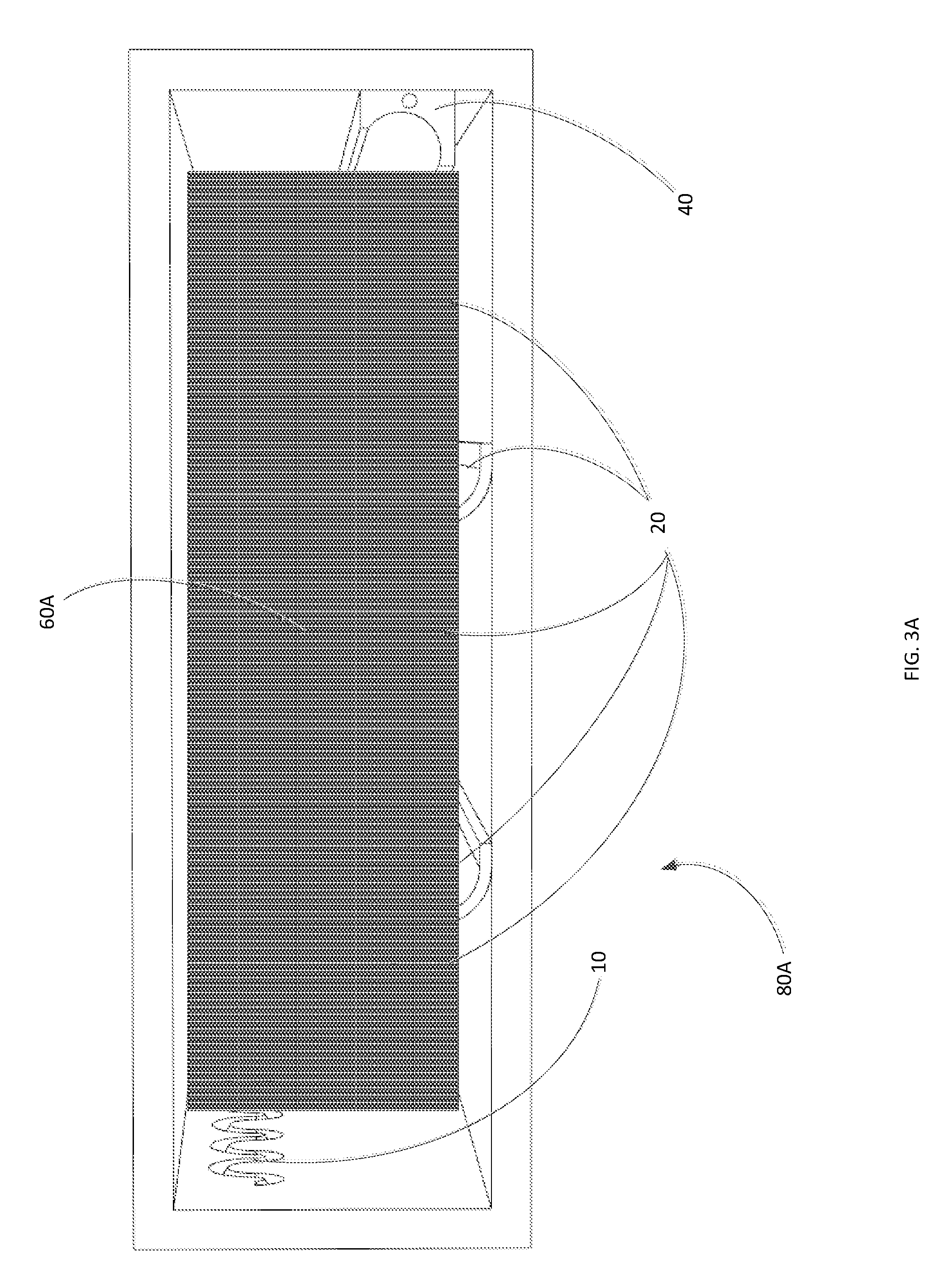

[0029]To achieve the objects and in accordance with the purpose of the invention, as embodied and broadly described herein, the invention comprises protective armor and a protective armor system for defeating projectiles, such that the projectiles and / or penetrating elements produced by the projectiles are blocked from penetrating the protective armor. According to embodiments, matter and / or energy associated with penetrating elements generated by a projectile impact on the armor may be at least partially deflected by one or more Active Inner Layers (AIL) of the armor. The AIL may, through active physical displ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap