Device for tying shoes

a shoelace and device technology, applied in the field of shoelace structure, can solve the problems of increasing manufacturing cost, easy loosening of shoelace knots, and difficult manufacturing, and achieve the effect of convenient user wear of footwear, avoiding loosening of shoelace knots, and quick wearing of footwear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

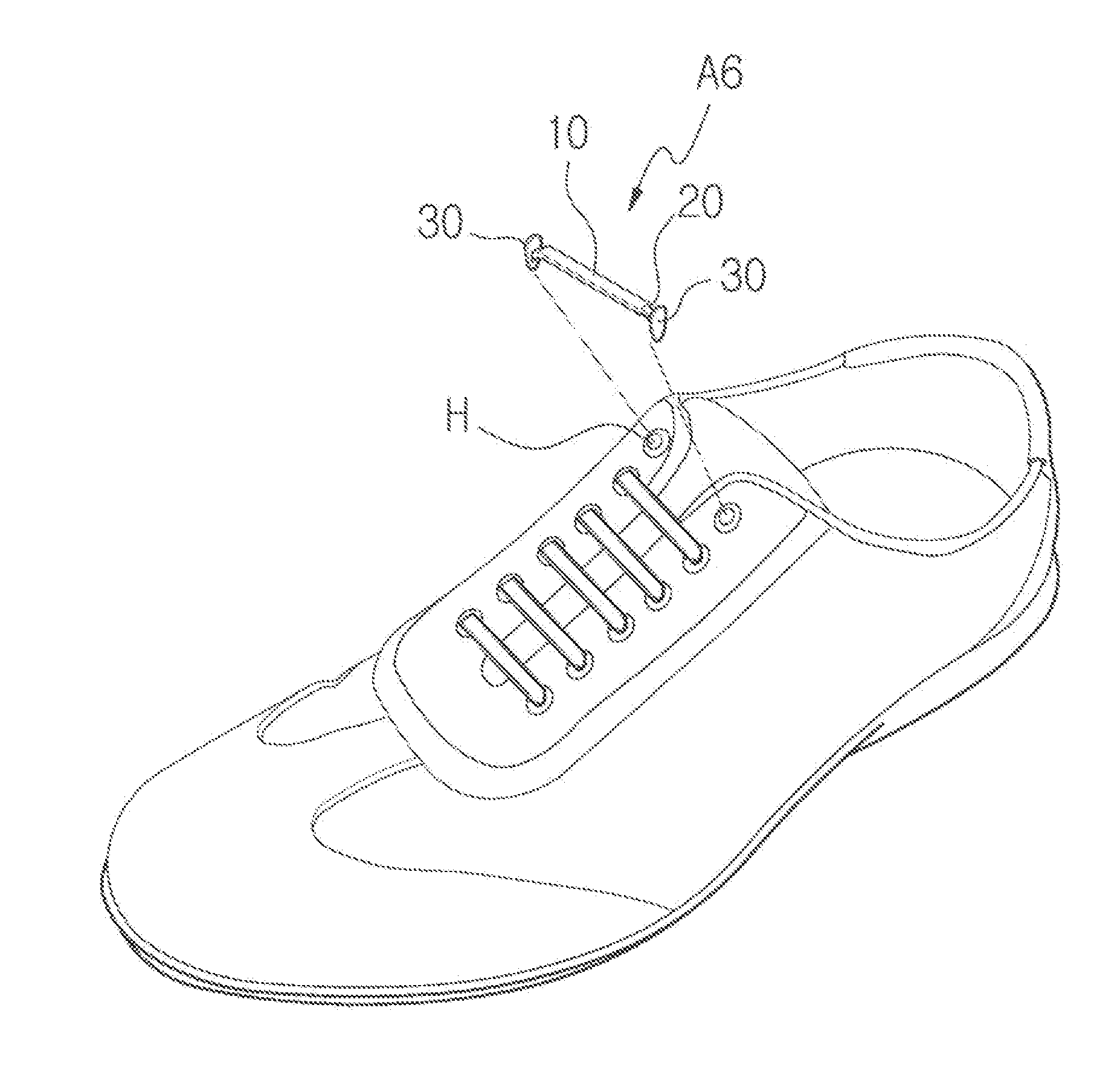

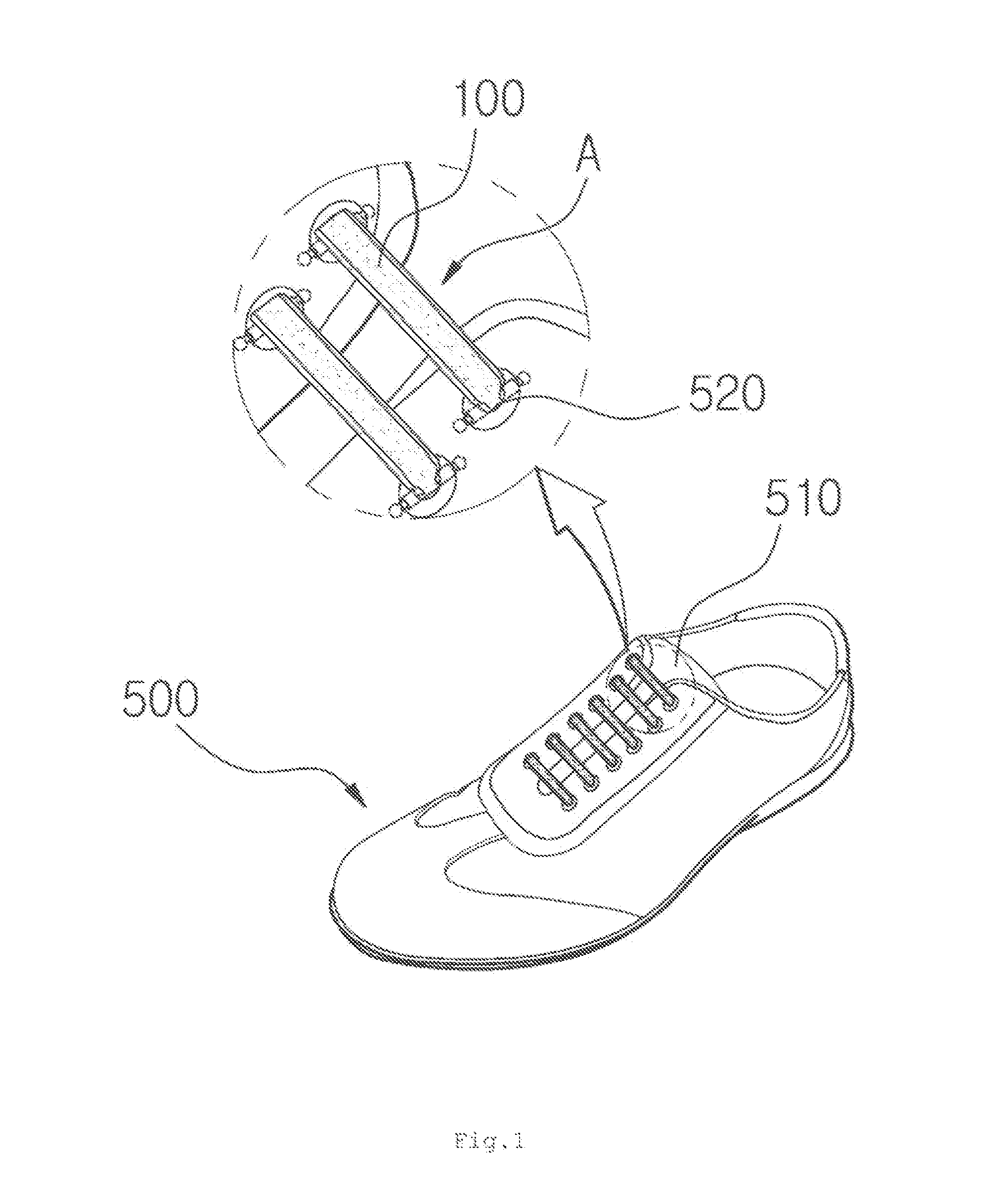

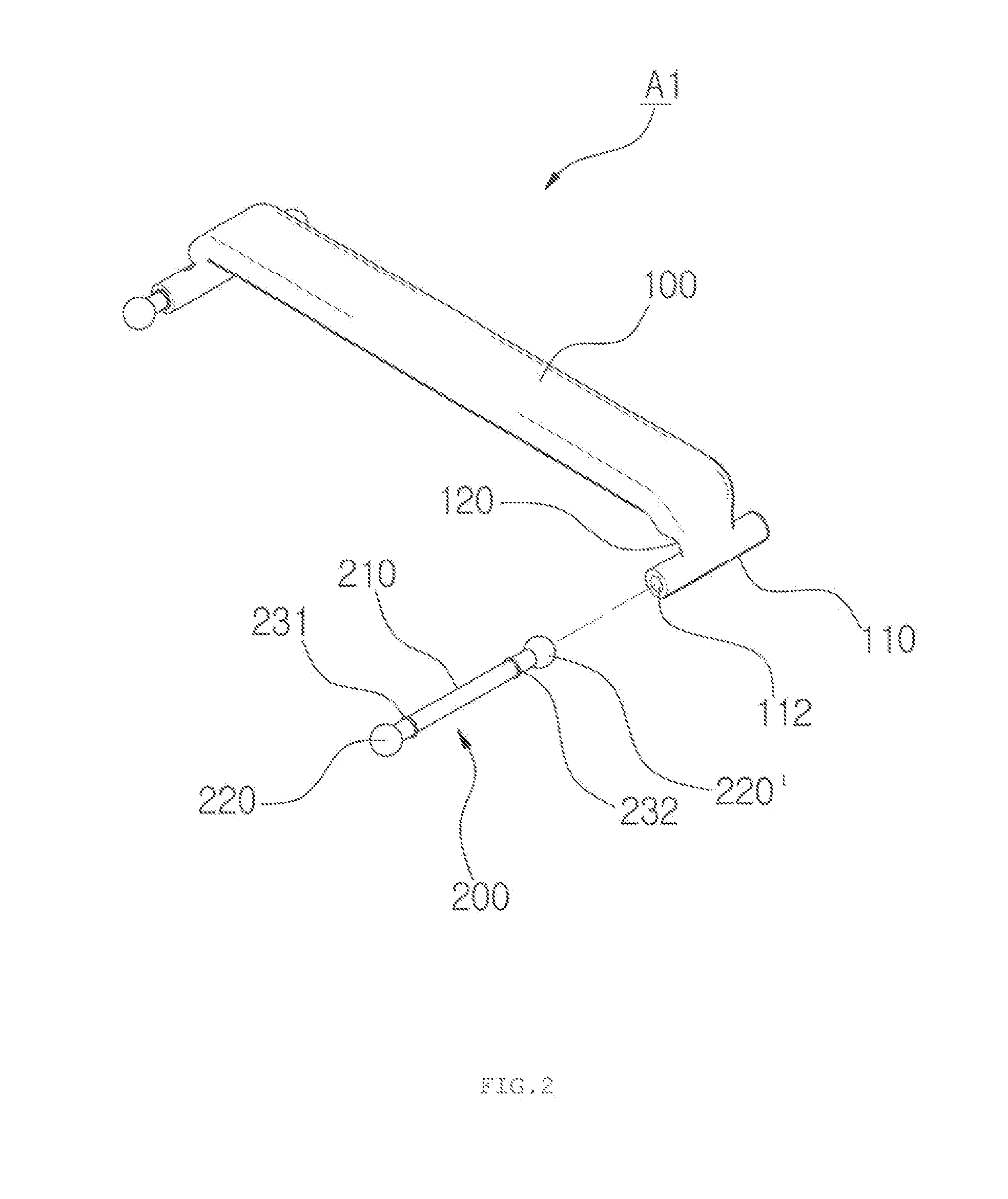

[0049]The footwear fastening structure A1 according to the present invention is configured such that it is tieably engaged in shoelace holes or eyelets of a shoe or sports shoe so as to fasten the shoe or the sports shoe tightly on a user's foot when he or she wears the shoe, the footwear fastening structure including: a band member 100 formed to have a predetermined length and having a pair of opposed engagement parts 110 respectively formed at both ends thereof, and a pair of opposed pin members 200 coupled to the engagement parts 110 of the band member 100 so as to be inserted into and hookingly fixed to the shoelace holes 520 of the shoe 500.

[0050]The band member 100 is formed to have a predetermined length using a material which is flexible and harmful to the human body such as rubber or silicon. The band member 100 can be largely divided into a rod shape and a strip shape depending on the kind of the shoe.

[0051]In other words, an elongated rod-like band member is applied to sh...

second embodiment

[0058]In the meantime, as shown in FIG. 4, a footwear fastening structure A2 according to the present invention is configured such that it is tieably engaged in shoelace holes or eyelets 520 of a shoe or sports shoe so as to fasten the shoe or the sports shoe tightly on a user's foot when he or she wears the shoe, the footwear fastening structure including: a band member 100 formed to have a predetermined length and having a pair of opposed engagement parts 110a respectively formed at both ends thereof, and a pair of opposed pin members 200 coupled to the engagement parts 110a of the band member 100 so as to be inserted into and hookingly fixed to the shoelace holes 520 of the shoe 500. The engagement part 110a is formed in a curved shape which is bent to have a low curvature.

[0059]Accordingly, the pin member 200a is formed in a curved shape which is bent to have a low curvature.

[0060]Thus, the bent engagement parts 110a are formed at the lower portions of the both ends of the band ...

third embodiment

[0073]In the meantime, as shown in FIGS. 5 to 7, a footwear fastening structure A3 according to the present invention is configured such that it is tieably engaged in shoelace holes or eyelets 520 of a shoe or sports shoe so as to fasten the shoe or the sports shoe tightly on a user's foot when he or she wears the shoe, the footwear fastening structure including: a band member 100 formed to have a predetermined length and having a pair of opposed engagement parts 110b respectively formed at both ends thereof, and a pair of opposed pin members 200 coupled to the engagement parts 110b of the band member 100 so as to be inserted into and hookingly fixed to the shoelace holes 520 of the shoe. The engagement part 110b is oriented vertically with respect to the ground surface.

[0074]Thus, the pin member 200b is fittingly coupled to the engagement part in a vertical direction and is moved vertically so that the pin member 200b can be fittingly engaged in the shoelace holes 520.

[0075]A metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com