Pregnant woman shoe with a single-layer upper

A shoe upper and single-layer technology, applied in the field of pregnant women's shoes, can solve the problems of formaldehyde hazards and affecting the health of children in the womb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

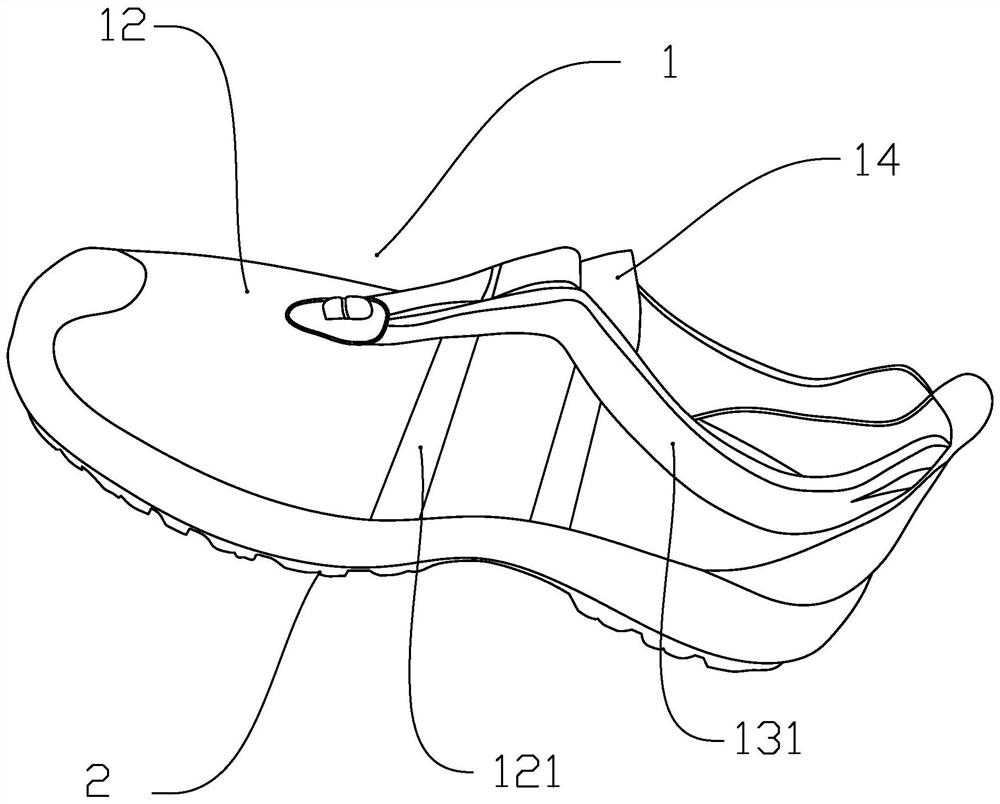

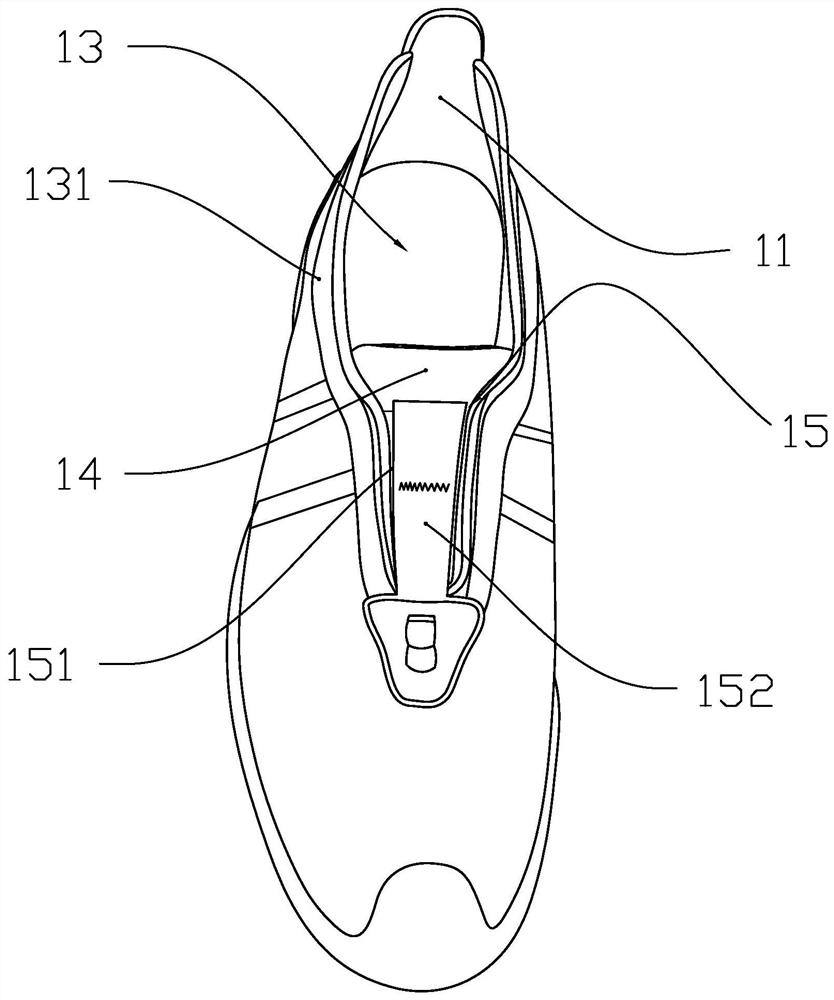

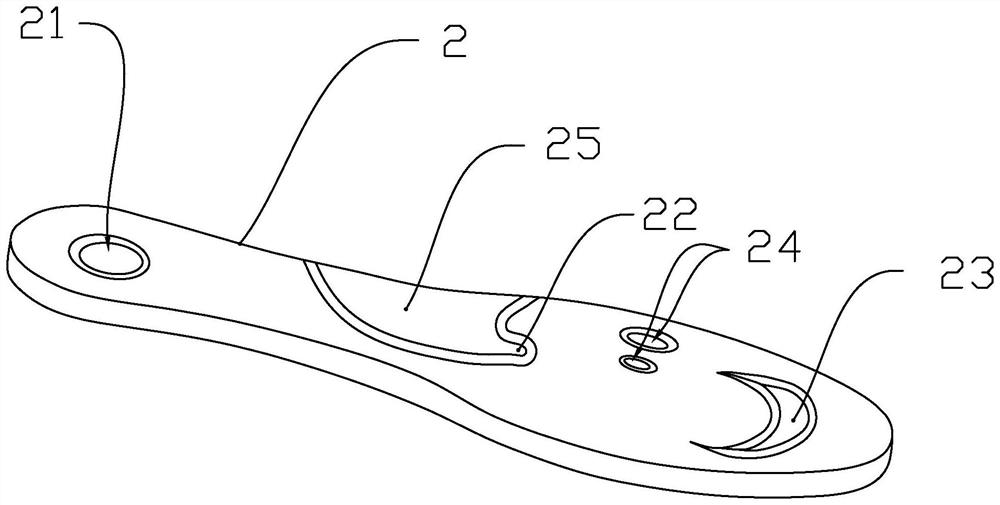

[0026] Specific embodiments of the present invention such as Figure 1-3 As shown, a maternity shoe with a single-layer upper includes a sole 2 and an upper 1 made of a single-layer leather, the smooth surface of the single-layer leather is the shoe lining 11 of the upper 1, and the rough surface is the shoe upper 1 Surface 12. The shoe upper 1 is made from the front of the first layer of leather, making its smooth surface as the shoe lining 11, and the rough surface as the shoe upper 12, which can improve the user's foot feel, and the contact with the instep surface is not only smooth but also breathable. In the prior art, The vamp 12 and the shoe lining 11 are generally bonded by hot-melt adhesive, which will volatilize harmful substances such as formaldehyde, which is likely to endanger the life and health of the user. The single-layer shoe upper 1 reduces this process, which not only requires less man-hours, less materials, and Cost saving, more environmentally friendly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com