Upwardly venting ridge vent and method of using same

a ridge vent and upward venting technology, which is applied in the direction of roof covering ventilation, heating types, building components, etc., can solve the problems of compressing the height of the vent and compromising the net free air flow area, and breaking up the otherwise clean lines of the shingled roof. , to achieve the effect of less effort, avoiding compression compromising issues, and being easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

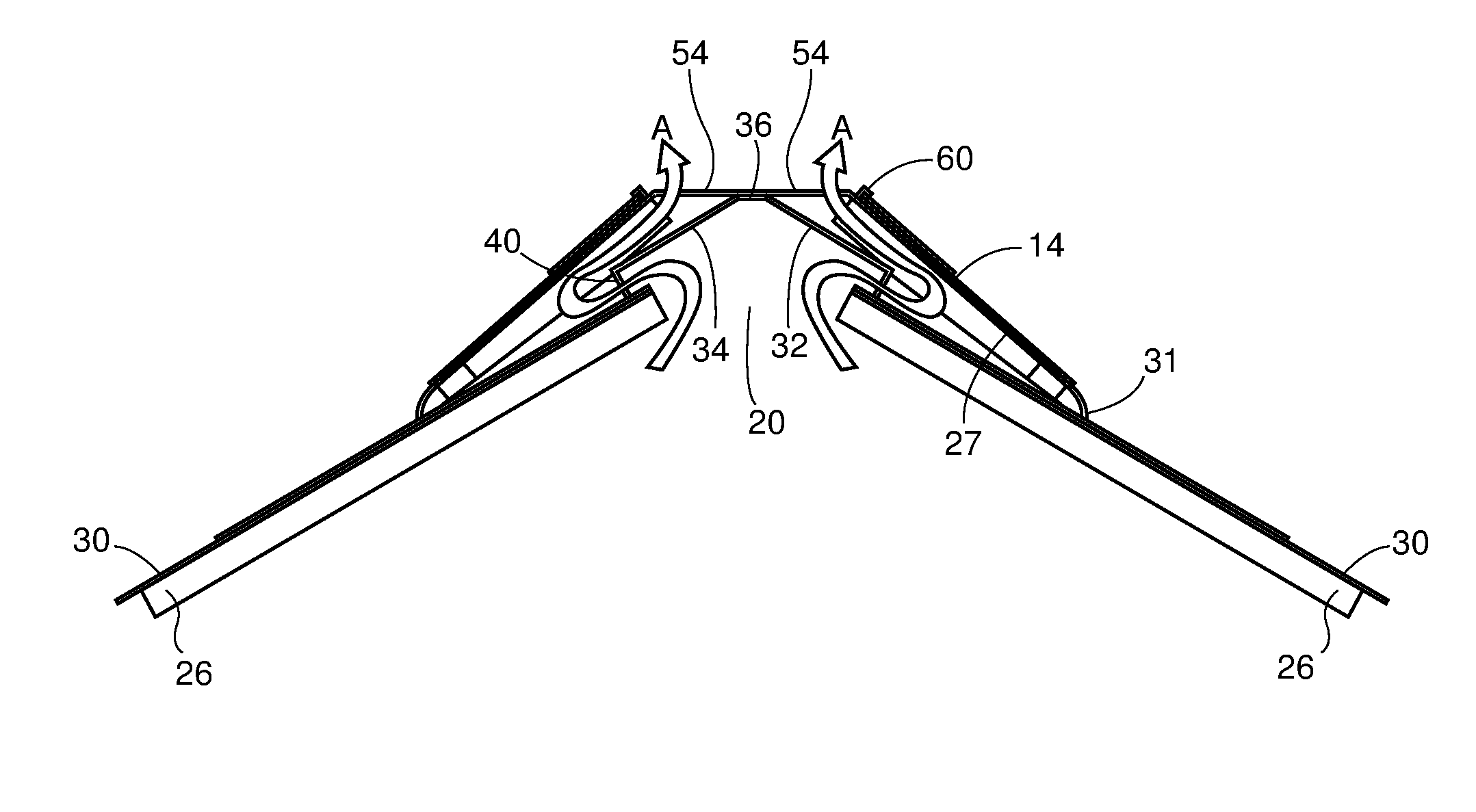

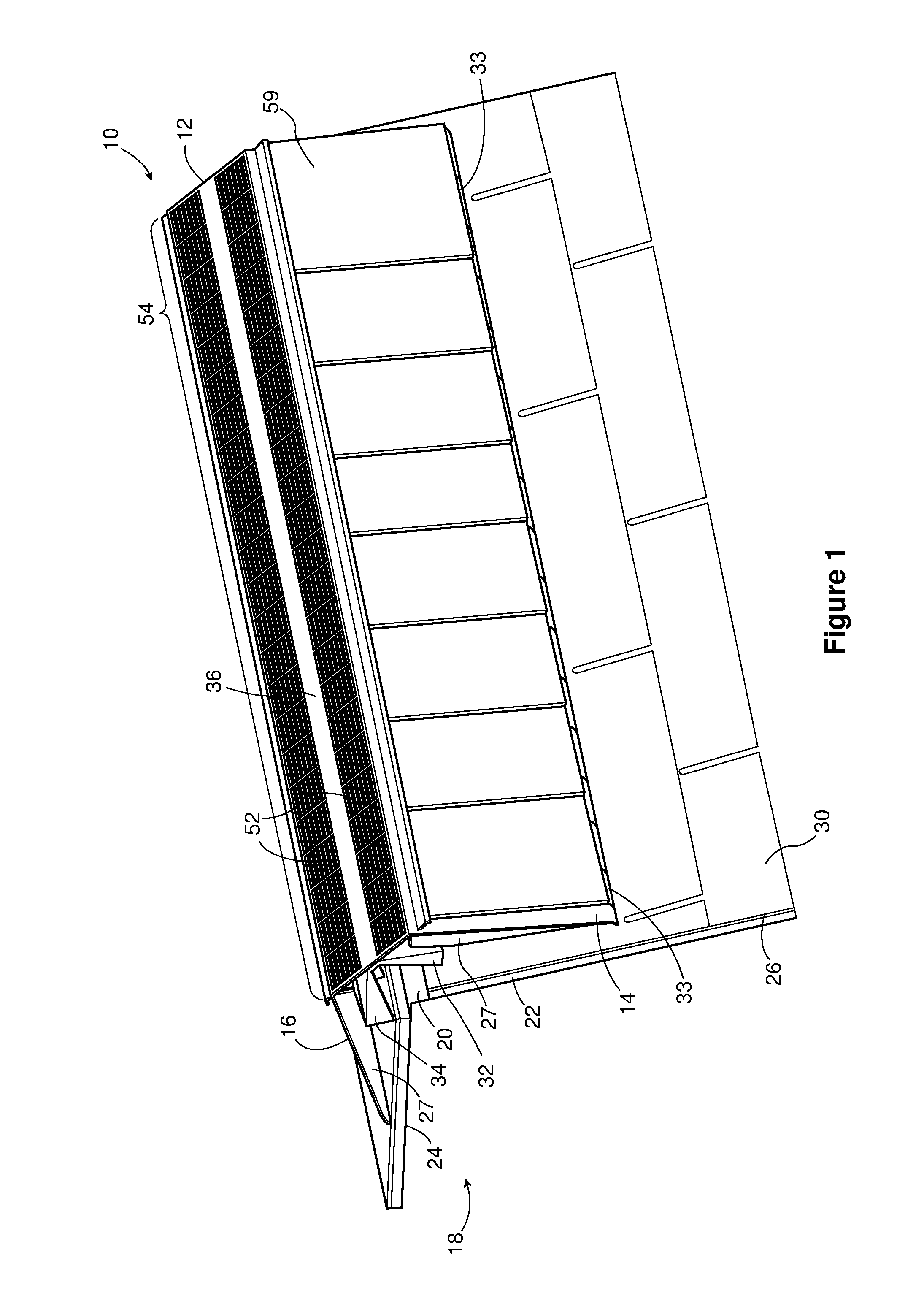

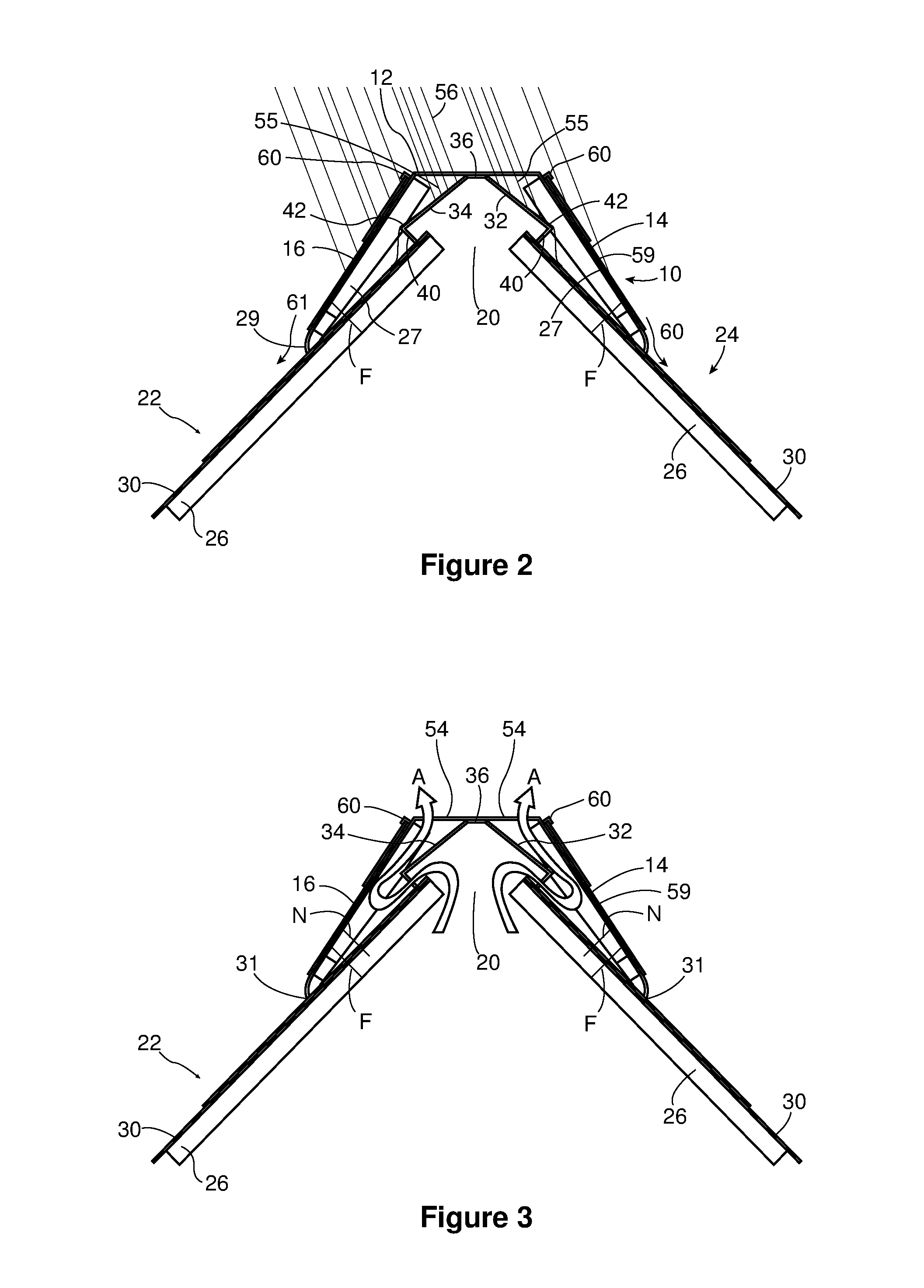

[0037]FIG. 1 shows a vent 10 according to the present invention. The vent 10 includes top surface 12, and side or outer attachment flanges 14 and 16. Also shown is a roof peak 18, with a ventilation slot 20 and sloping roof sections 22 and 24. The vent 10 may straddle the ventilation slot 20 as shown. The sloping roof sections are comprised of a roof deck, such as plywood 26, supported by rafters in the usual way, and overlain with shingles 30, in the normal manner. The outer attachment flanges 14, 16 extend down on either side of the roof peak 18 and may be secured to the roof deck 26 in a normal manner such as by nails, screws, glue or the like but most typically with nails. Reinforcing ribs 27 may also be formed underneath the outer attachment flanges to strengthen the flanges and to provide a small drainage gap 29 (FIG. 2) between a lower edge of the outer attachment flanges 14, 16 and the shingles 30. Weeping holes 33 may also be provided to help drainage and water flow. Most p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com