Position Sensing in a Probe to Modify Transfer Characteristics in a System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

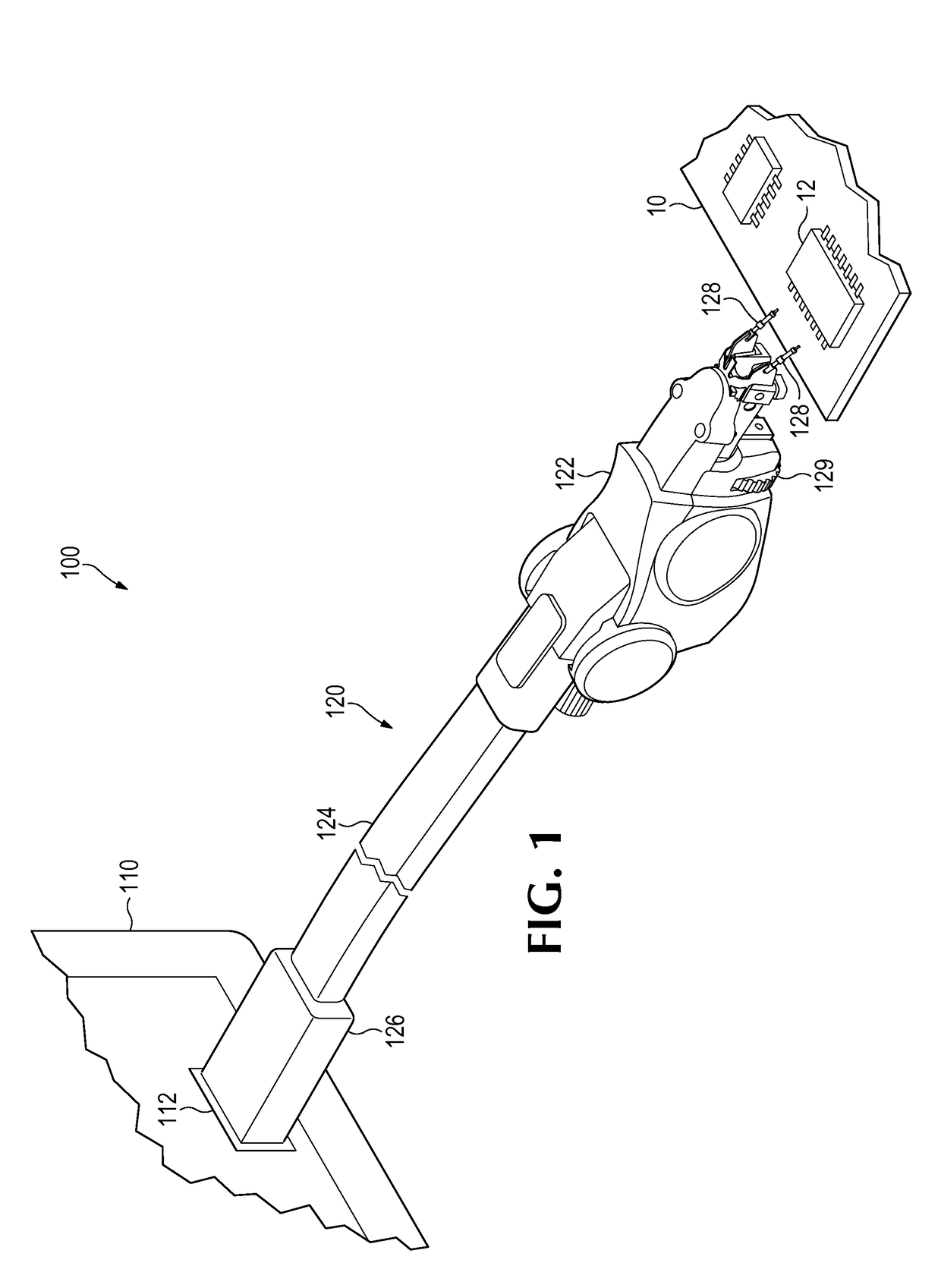

[0017]FIG. 1 depicts an example test and measurement system 100. The test and measurement system 100 includes a test and measurement instrument 110, such as an oscilloscope, as well as a test and measurement probe 120. The test and measurement probe 120 connects to an input 112 of the test and measurement instrument 110. The probe 120 may be used to make electrical contact with one or more test points in a user's device-under-test (DUT) 10, which may be a circuit board. For example, the probe 120 may be positioned by a user to make physical contact with one or more pins on an integrated circuit (IC) 12 placed on the circuit board 10, in order to monitor the electrical signal present at those points in the DUT 10, that is, the “measured signal.”

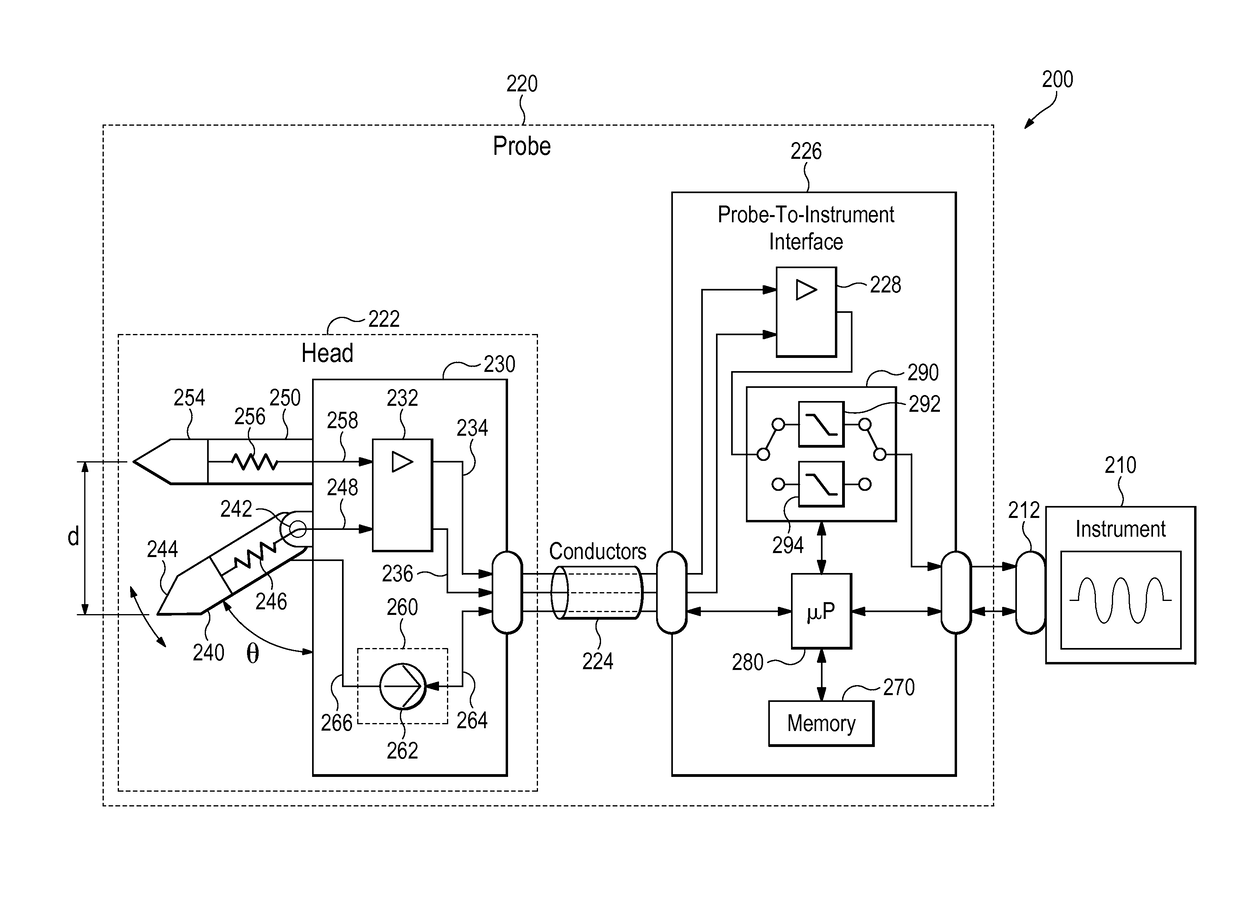

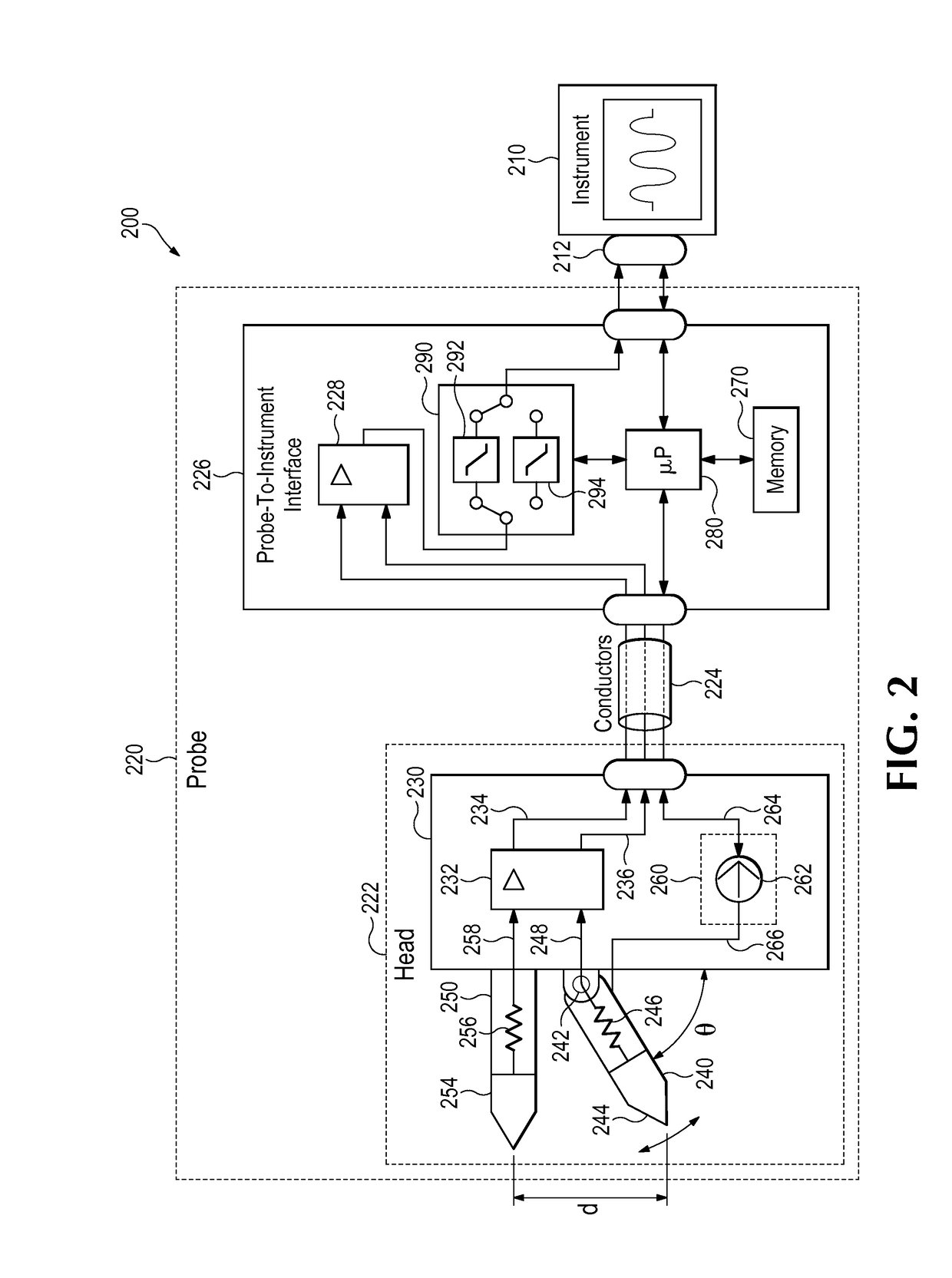

[0018]The probe 120 generally includes a probe head 122, a probe-to-instrument interface 126, and one or more conductors 124 between the probe head 122 and the probe-to-instrument interface 126. As a browser probe, the probe head 122 is genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com