Self-tie bow tie made with no fabric fasteners, hooks or pile fasteners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

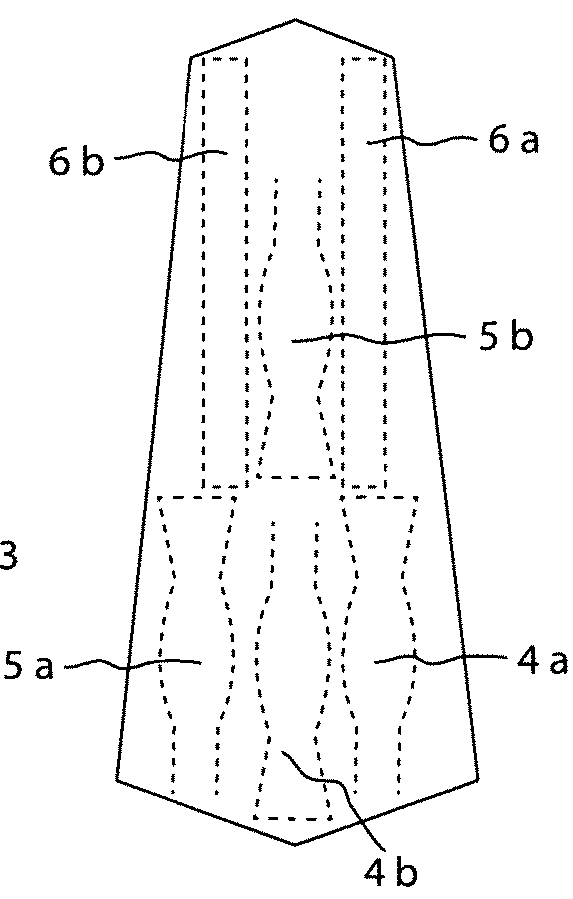

[0016]Referring to FIG. 1 through FIG. 4, a neck band joined fabric material 6a &6b employing my invention may be seen. The neck band basically comprises of two identical fabric portions 6a &6b derived from FIG. 4. The bow portion 4a, 4b &5a, 5b comprises of four identical shapes sewn together then joined to 6a &6b fabric material to form a bow tie. The bow portion may be typically 2″ in width and 10″ to 12″ in length. Silk for formal attire is customary, wovens, cotton and satin are common other fabrics used for the bow tie.

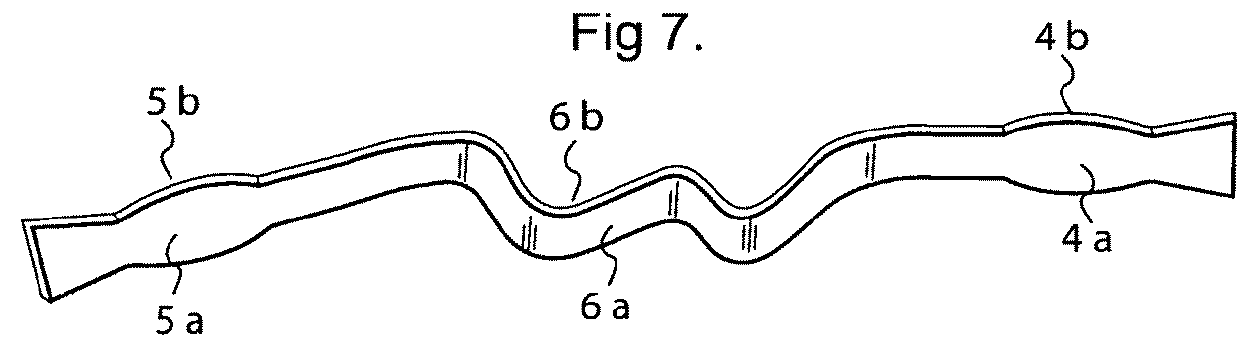

[0017]The neck band portion FIG. 5 is joined to FIG. 6 bow-shape 4a, 4b &5a, 5b. It has a length of the neck tie fabric material which may vary from 12″ to 18″ in length. At both 7 ends, 6a &6b of the neck band portions and 4a, 4b &5a, 5b bow-shape are attached.

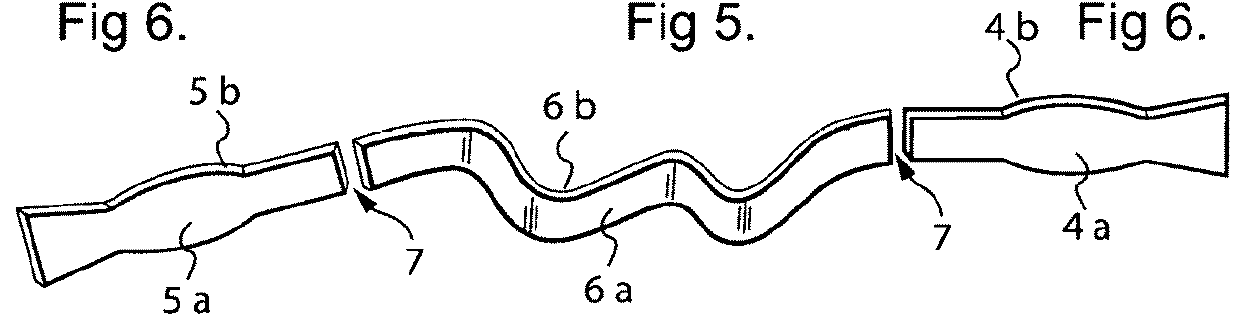

[0018]FIG. 7 shows the complete assembled bow tie employing neck band and bow-shape.

[0019]FIGS. 8 & 9 shows the self-tie bow tie FIG. 7 tied. Front and back views.

[0020]The above-described embodiments of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com