Parker true to form bow maker

a true-to-form, bow maker technology, applied in the direction of ribbon-threading apparatus, ornamental textile articles, textiles and paper, etc., can solve the problem of limiting the number of bows a person

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

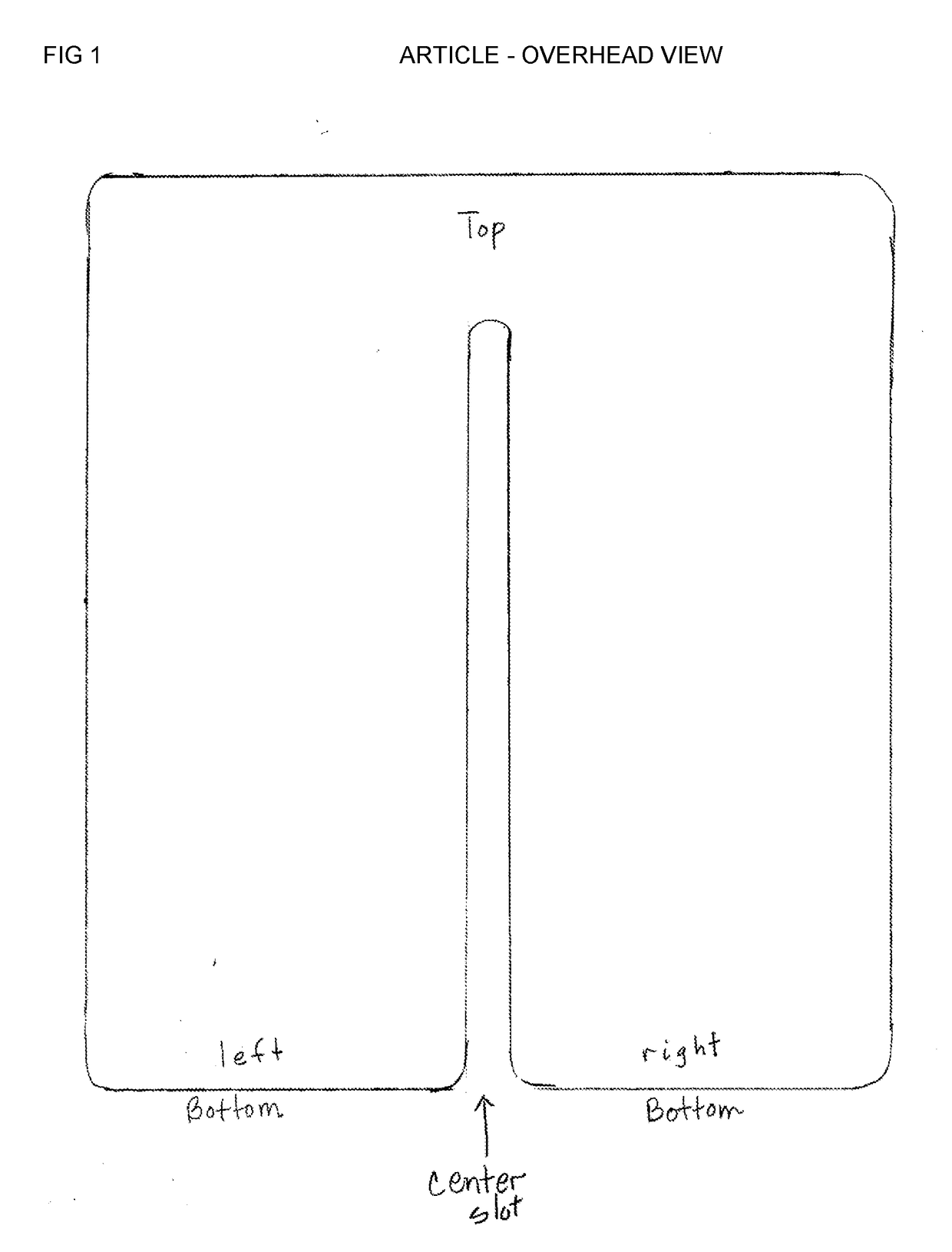

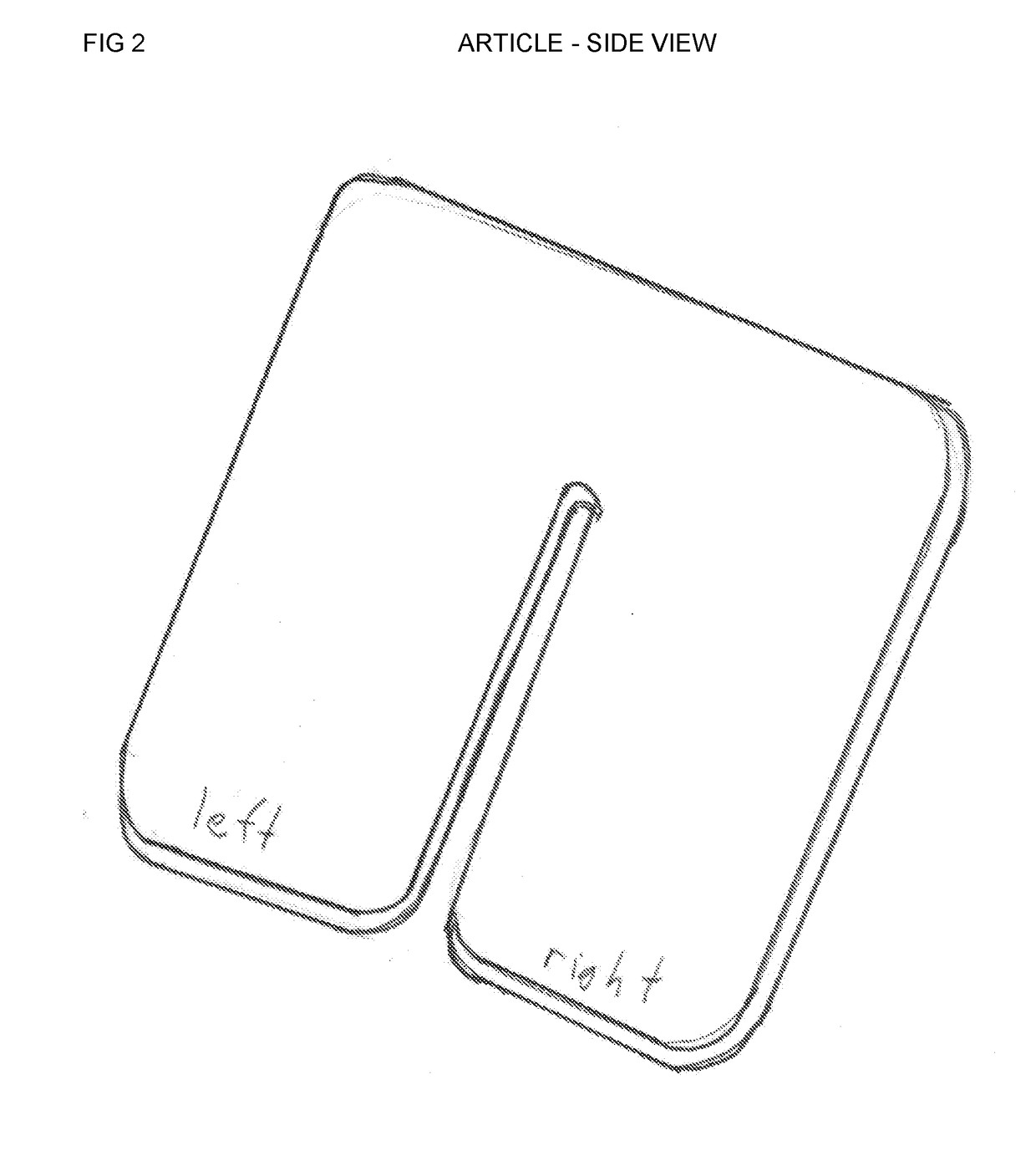

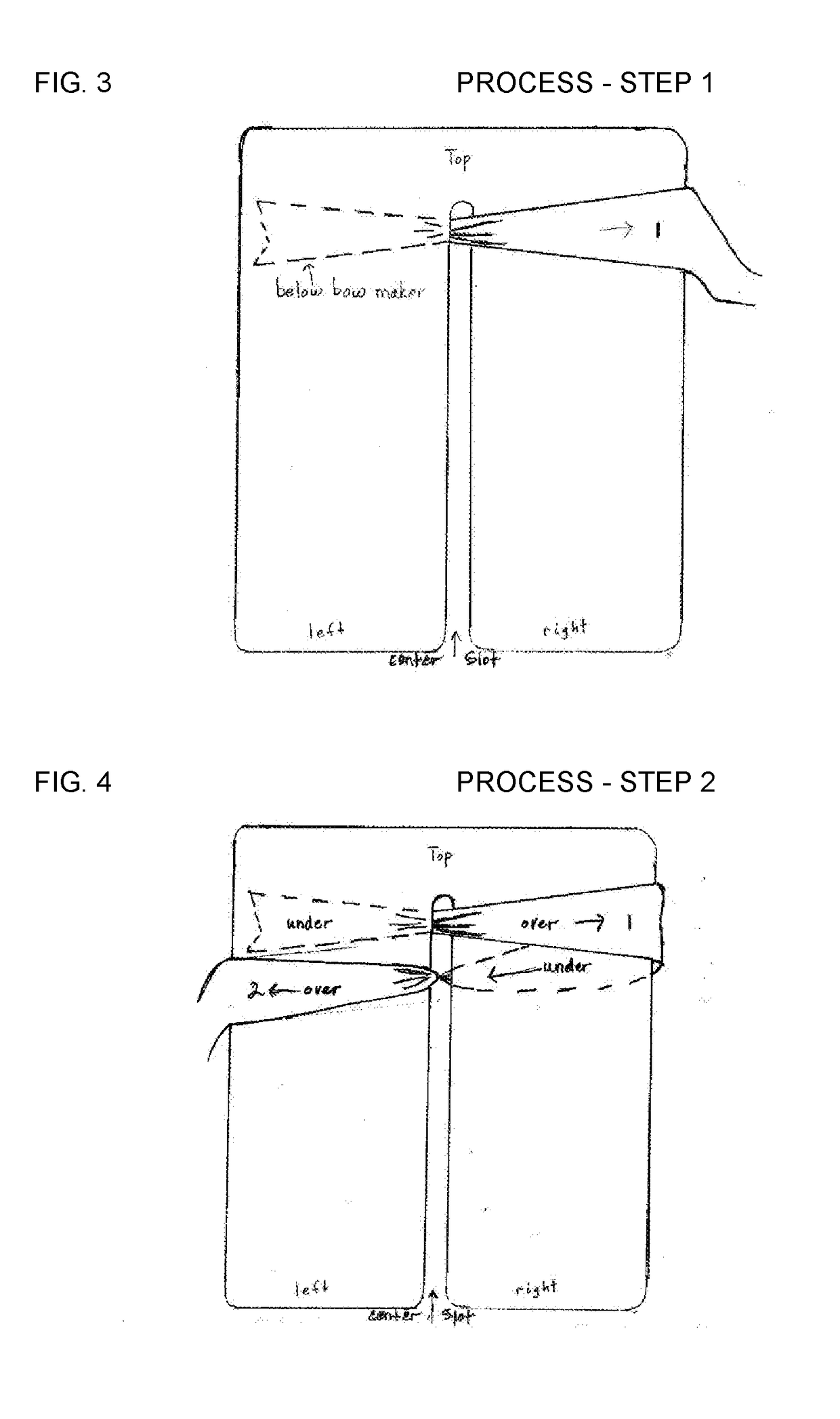

[0016]The invention is a manufactured article rectangular in shape and the process utilizing the manufactured article as a tool to create decorative, ornamental bows from wire-edged ribbon.

[0017]The article is cut from flat, smooth, firm but flexible material such as sheet plastic or glossy, thick card stock. It is a flat, rectangular shape, whose width is equal to the diameter of the desired bow to be made, and the length is 1″ longer than the width. A slot is cut vertically up the middle of the rectangle, beginning at the bottom edge, perpendicular to the bottom edge, and ending 2″ short of the top edge, dividing the rectangle into 2 matching parts—the right side and the left side equal in width, and which are connected at the top edge by a 2″ wide bridge. The width of the slot ranges in size from ¼″ to ½″. Optimum is ⅜″. The 6 corners are rounded to remove sharp corners. Each article makes a bow of a particular size. Articles of various sizes would be required to make bows of cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com