Chemical mixing and pumping unit and methods for oilfield operations

a technology of chemical mixing and pumping unit, which is applied in the direction of rotary stirring mixer, transportation and packaging, and well accessories, etc., can solve the problems of improper mixing, unstable mixing, water splashing and bubbles inside the tank,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

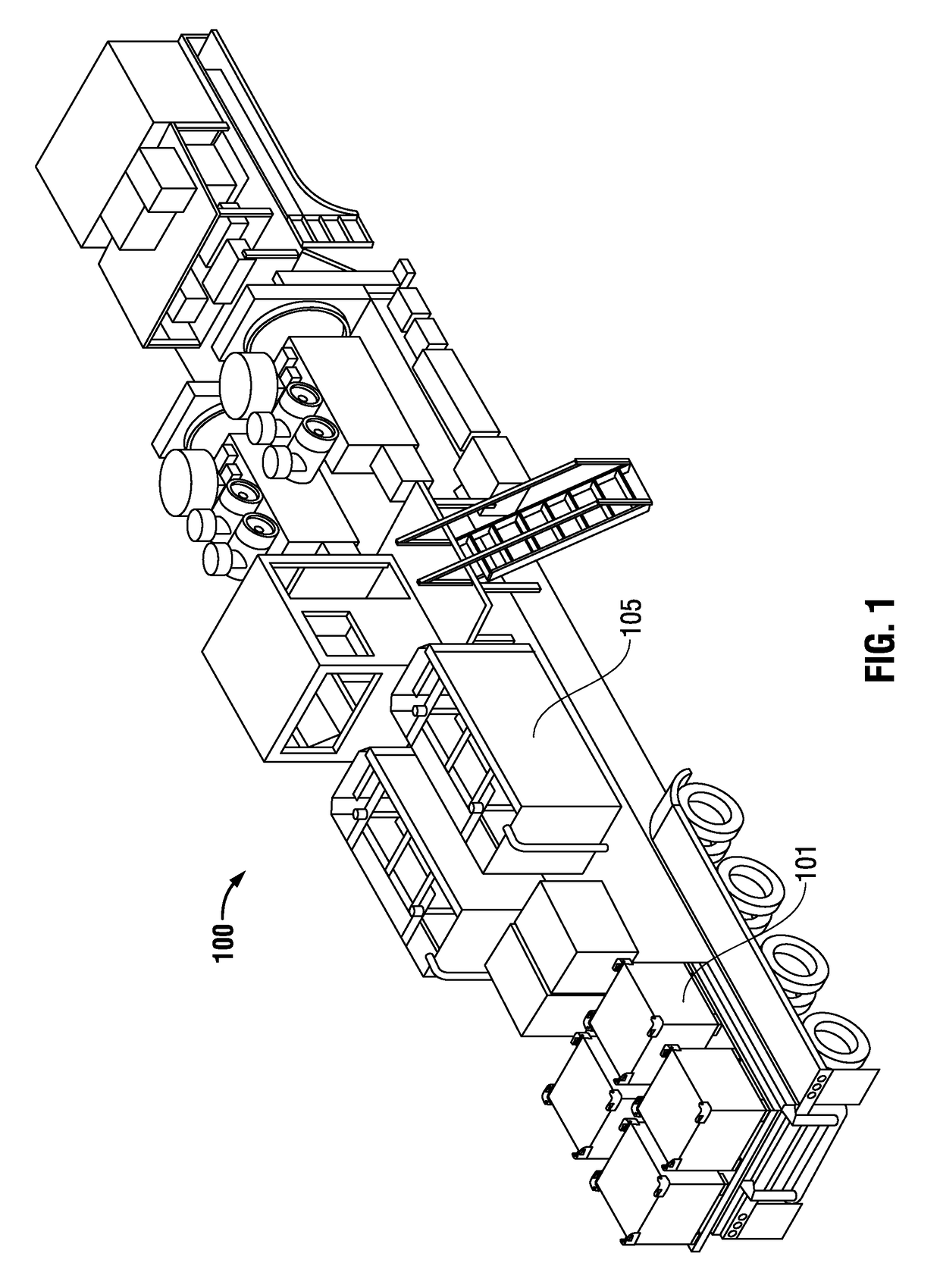

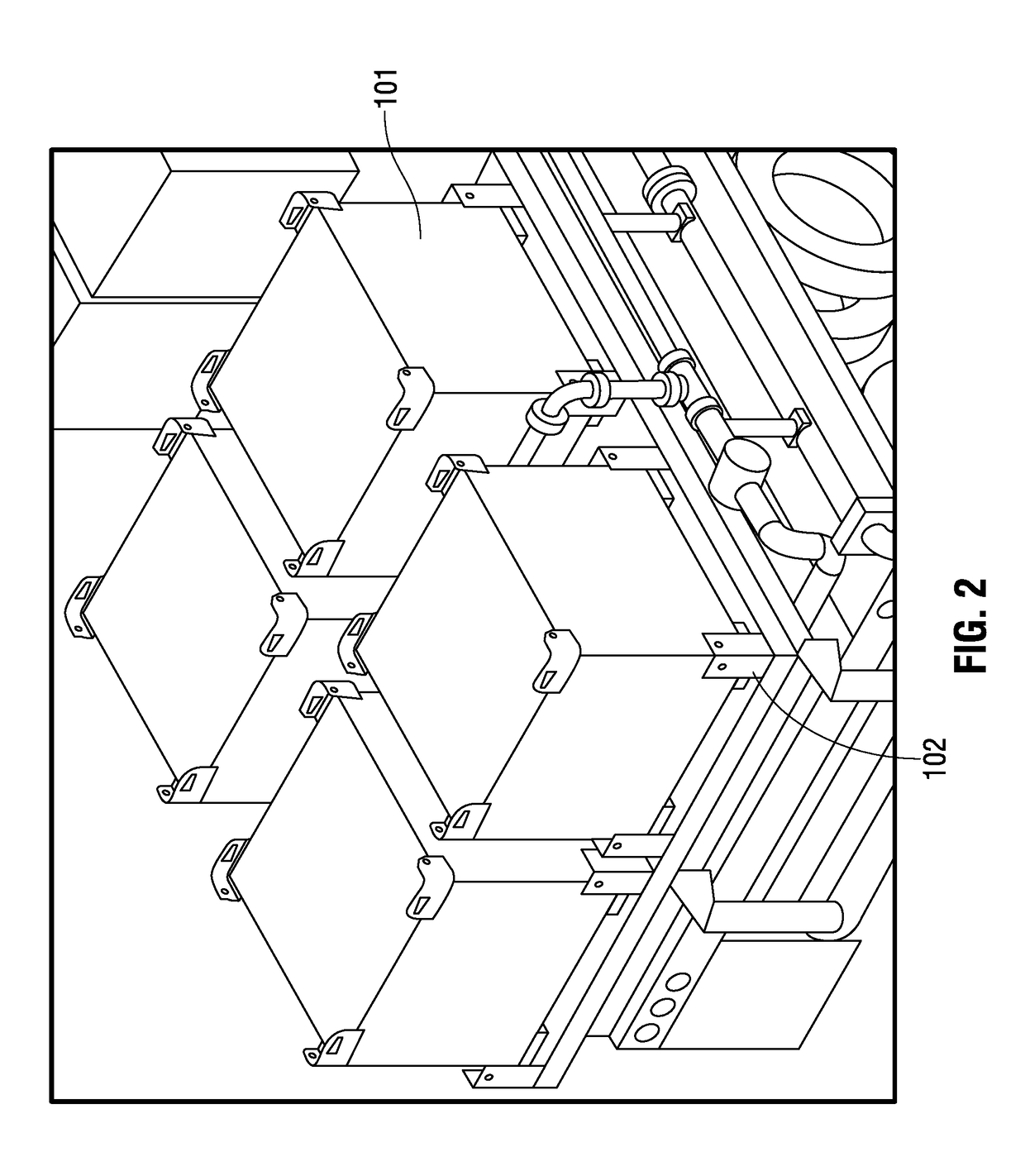

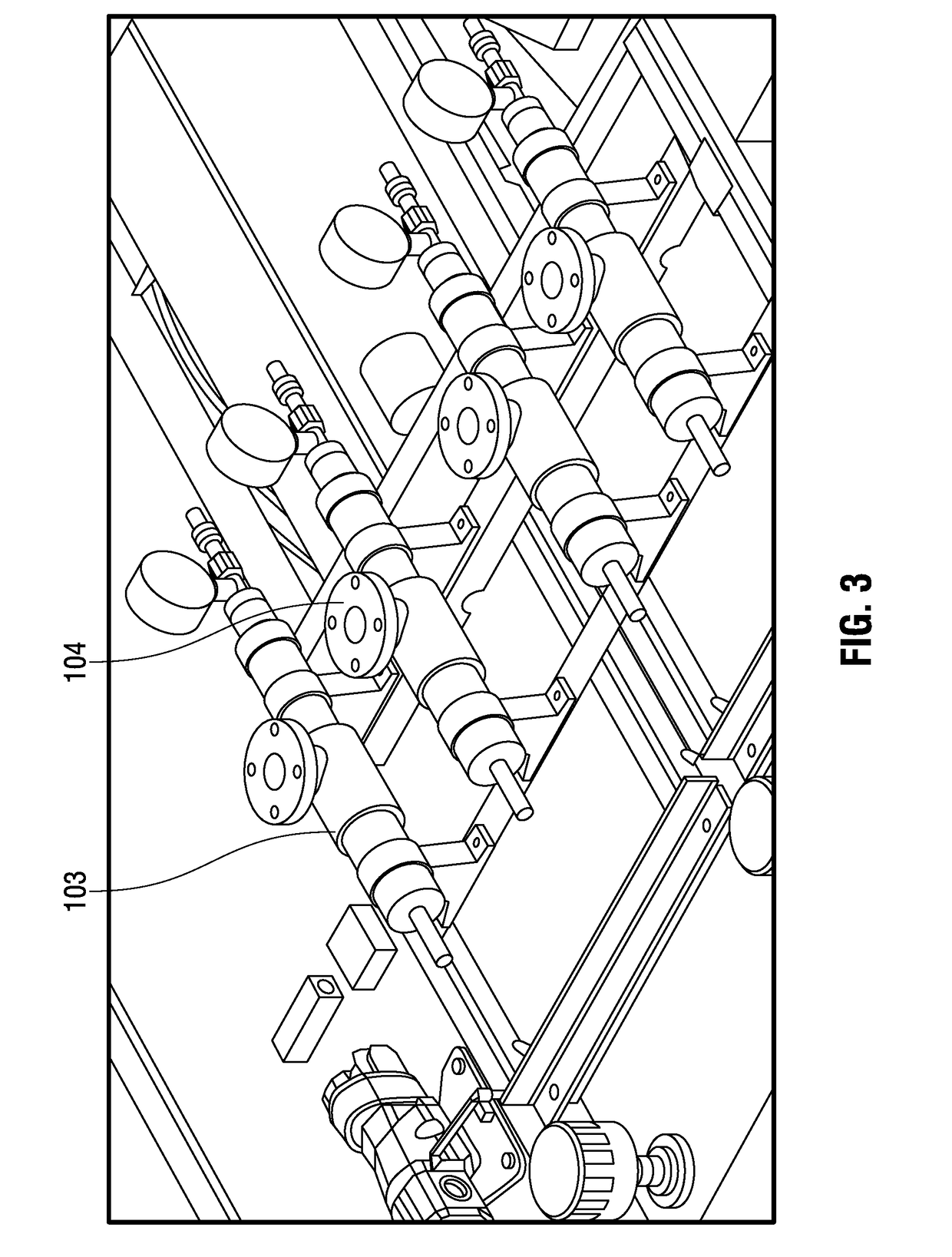

[0014]Embodiments disclosed herein relate to chemical mixing and pumping units and methods for oilfield operations. Other embodiments disclosed herein relate to chemical mixing and pumping units and methods for coiled tubing oilfield operations. Yet other embodiments disclosed herein relate to mixing tanks used on chemical mixing and pumping units, and related methods of operating the mixing tanks.

[0015]A chemical mixing and pumping unit may provide for onboard storage of one or more chemicals either permanently mounted on the pumping unit, or affixed using a cradle, skid-based, or mounting hardware either permanently affixed or temporary. The chemical storage may be contained in a permanently mounted tank or tanks of variable capacity, or temporarily attached tanks of variable capacity. The chemical storage may also be divided internally to allow for further chemicals to be stored in any capacity. These tanks may be constructed of any number of materials including plastic, metal, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com