Expansion tank with improved single diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

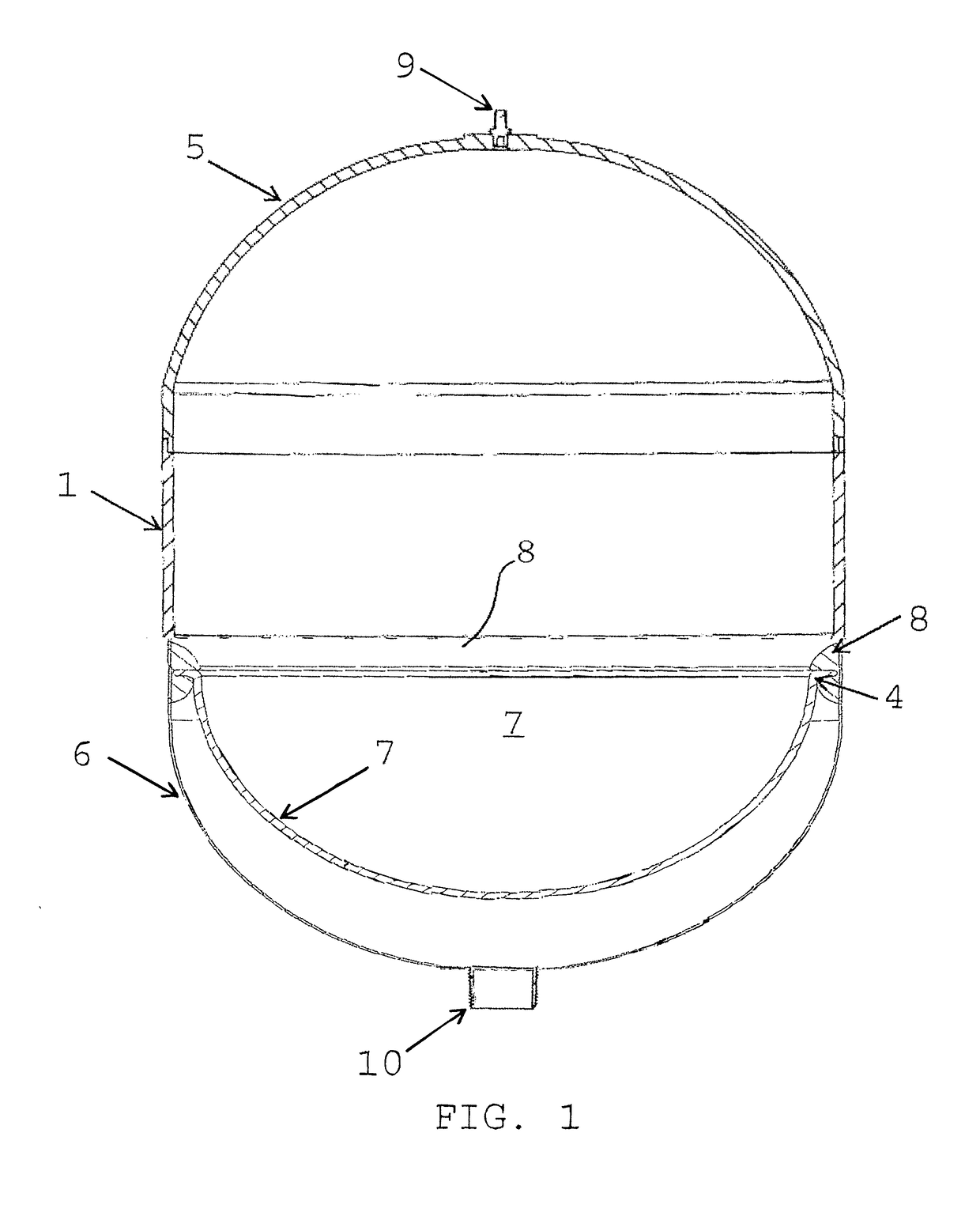

[0015]FIG. 1 is a cross section of an embodiment of a tank in accordance with this invention, with a single diaphragm, connected to a tank inner wall by a circumferential coupling ring 8; the tank is charged with pressurized gas, such as air, but empty of liquid, e.g., water. The tank comprises a substantially cylindrical housing section 1, joined to substantially hemispherical domes 5 and 6, with a single diaphragm 7 that is connected to an inside wall surface of the lower dome 6, adjacent the joint with the central cylindrical section 1. The peripheral edge 4 of the diaphragm 7 is circumferentially connected to the diaphragm coupling ring 8. Dome 5 further comprises an air valve 9, which allows the upper volume of the tank to be charged with air or an inert gas. Dome 6 further comprises a threaded connection 10, through which water can flow into the lower volume of the tank, under the diaphragm 7.

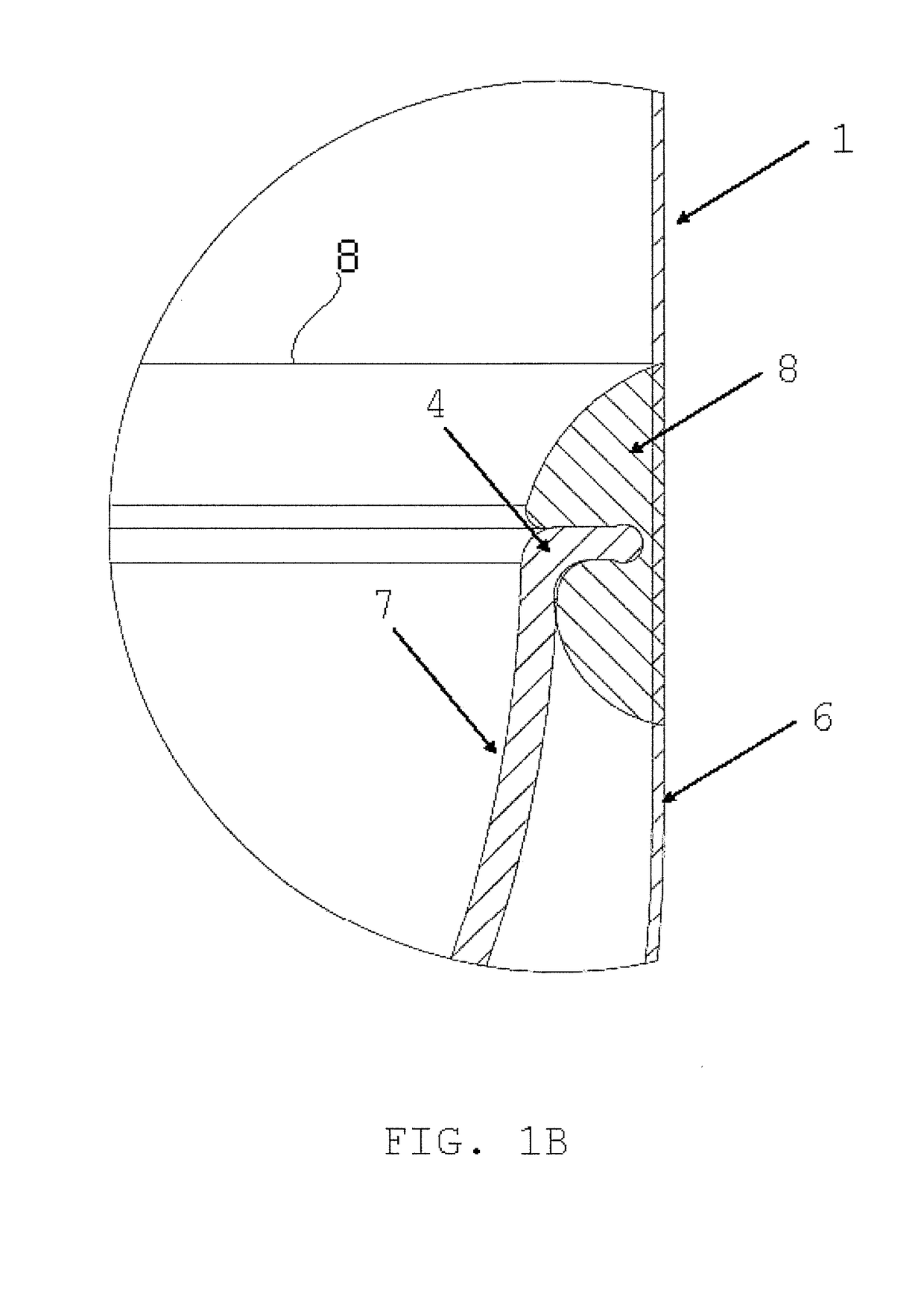

[0016]FIG. 1B shows a partial expanded view of a tank wall near the coupling ring 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com