Finger tab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

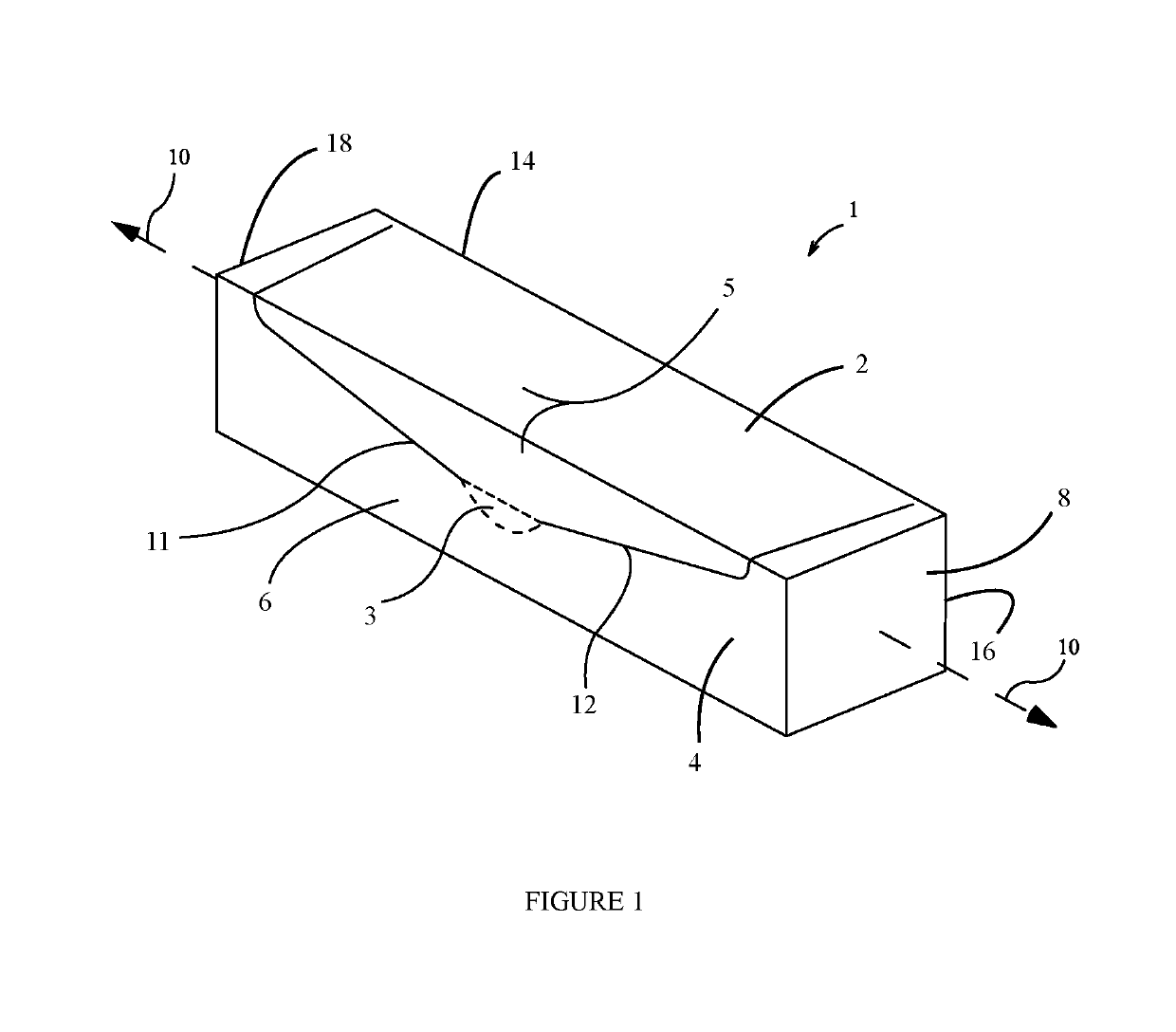

[0035]User data (via consumer testing) comparing the inventive carton and that of comparative examples is summarized. Stacking transportation tests for the inventive carton are also summarized. The carton comprising the finger tab of FIGS. 1 and 2 is an example of the present invention. The inventive carton is compared to comparative examples (A-G) of FIGS. 4-9. The dimensions of the carton (229 mm×55 mm×44 mm), type of paperboard (i.e., 350 g / m2) of virgin material, and ½ cut line of weakness (opposing blades 5 mm apart) defining the flap, are the same for each of cartons (i.e., inventive and comparative), except for the finger tab.

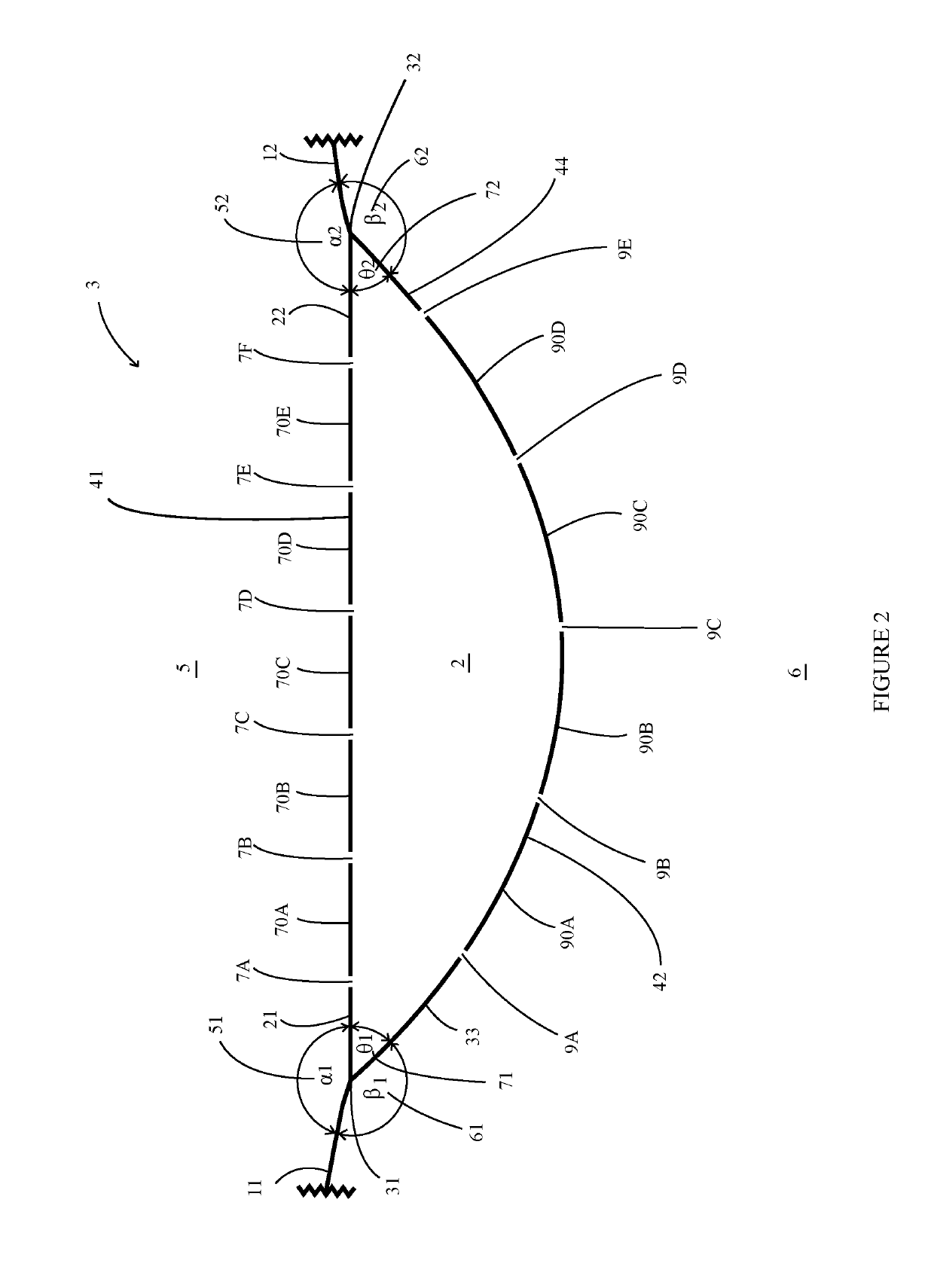

[0036]The finger tab (3) of the invention of FIG. 2 comprises a first intersection (31) formed by a first ½ cut line of weakness (11) intersecting a first perforation (21) wherein the perforation is 3.8 mm long and the linkage immediately adjacent the (7A) the first perforation (21) is 1 mm in length. A second intersection (32) is formed by a second ½ cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com