Splice connectors for hollow structural segments and methods of making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

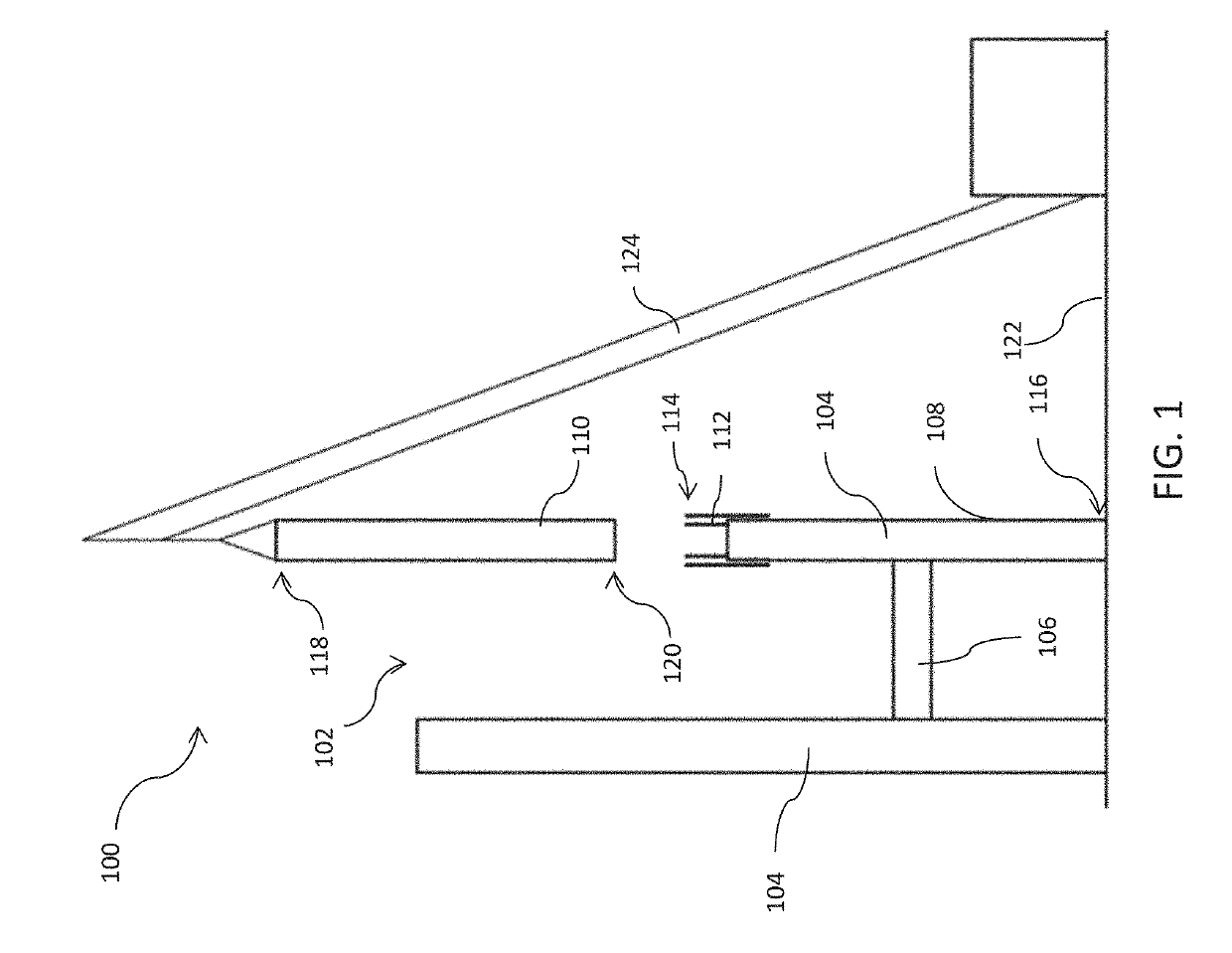

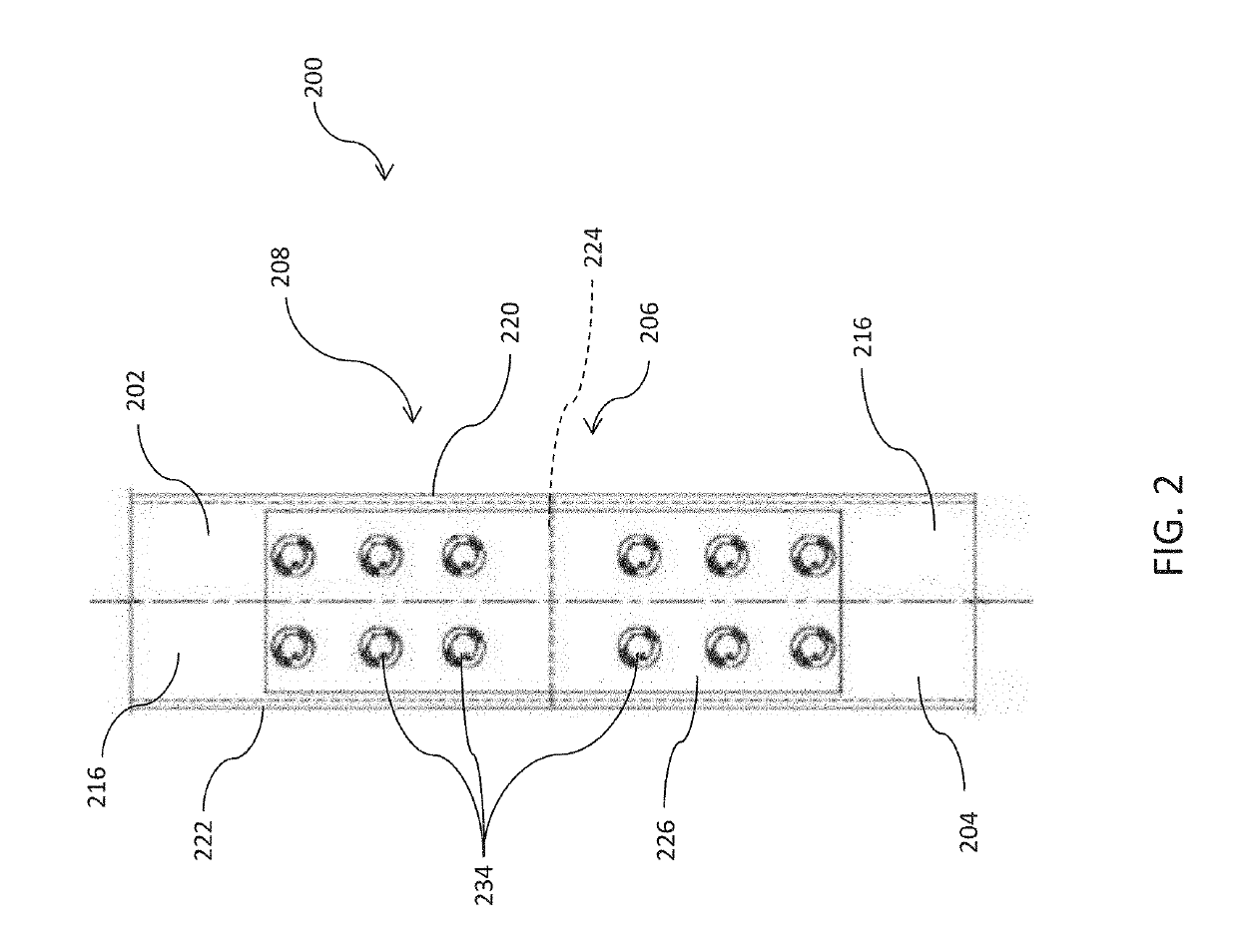

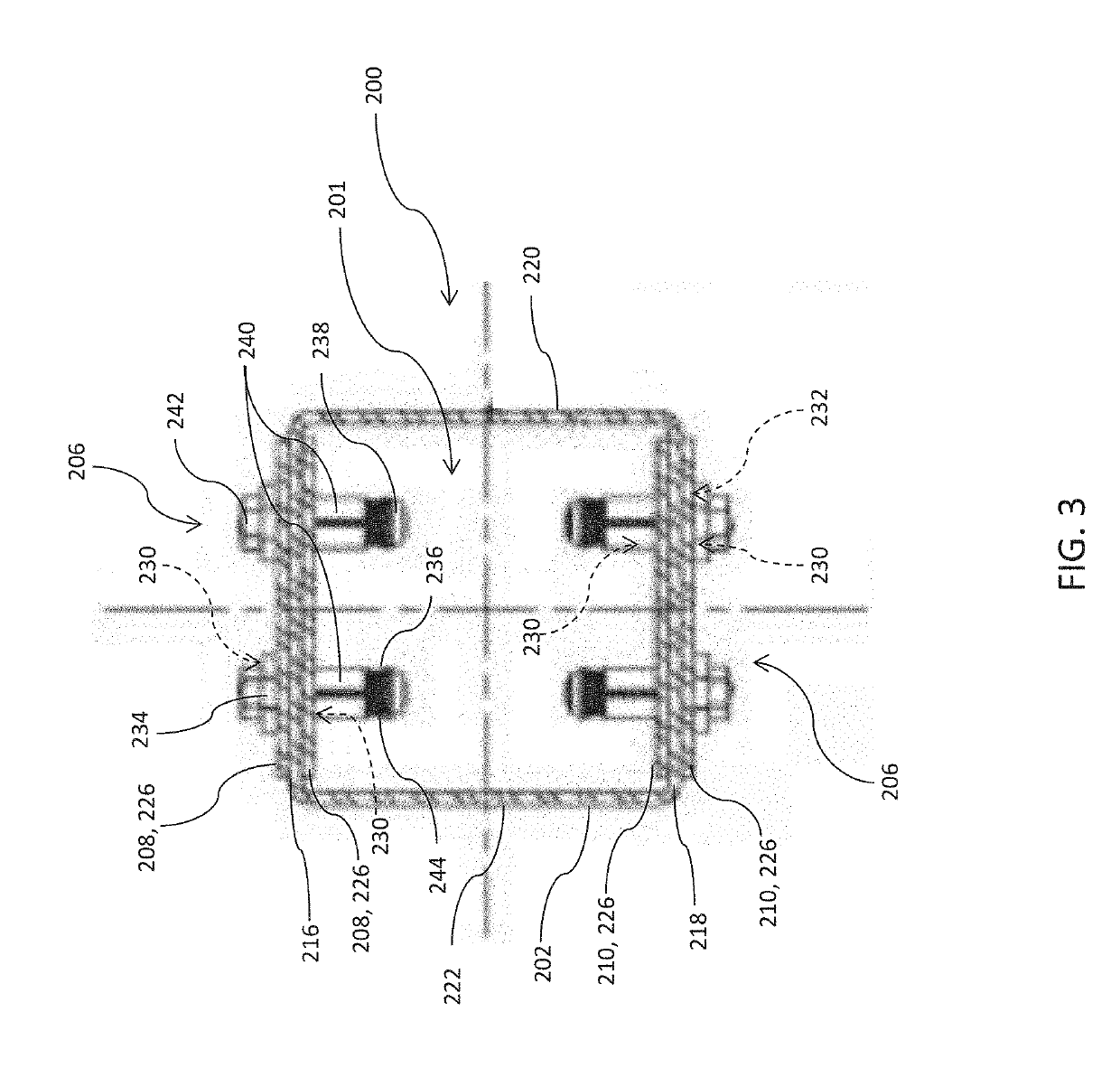

[0011]The embodiments described herein include connectors for coupling hollow structural section (HSS) column segments into columns, and methods of making the connectors. More specifically, the connectors include pairs of splice plates, and each pair is coupled respectively to the interior and exterior surfaces of a wall of the column segments, across the interface of the adjoining column ends, using fasteners. The connectors facilitate assembling, at the point of use, column segments to form moment-resisting structural columns without the need for welding or other techniques. Moreover, the connectors facilitate meeting all structural performance requirements for a statically loaded tension / compression member in a building frame.

[0012]The description should enable one of ordinary skill in the art to make and use the connectors, and the description describes several embodiments of the connectors, including what is presently believed to be the best modes of making and using the splice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com