Chiral compound, liquid crystal composition containing the same, optically anisotropic body, and liquid crystal display device

a liquid crystal composition and compound technology, applied in the field of liquid crystal materials, can solve the problems of low solubility, complicated synthesis process, low hip value of chiral additives in the prior art, etc., and achieve the effect of reducing the addition amount of chiral compound, good solubility and high htp valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

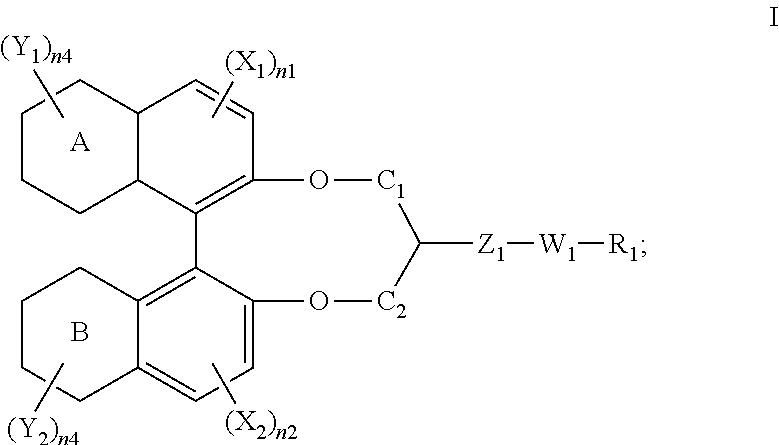

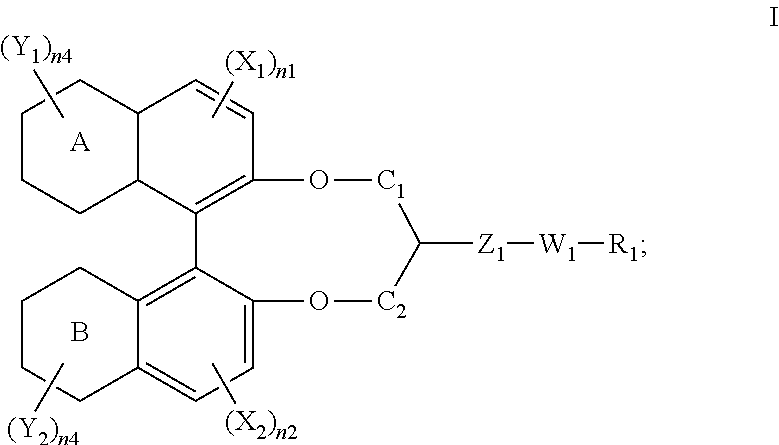

[0050]The structural formula of the polymerizable compound is as represented by the following formula:

[0051]The steps of the preparation thereof are as follows:

[0052]Step 1. The Preparation Route is as Follows:

[0053]Specific Operation Procedures of the Preparation:

[0054]30.7 g (0.20 moles) of diethyl malonate is dissolved in 200 ml of anhydrous ethanol, 4.7 g (0.20 moles) of sodium metal is added under nitrogen protection, 30 g (0.187 moles) of colourless liquid bromocyclopentane is added dropwise after sodium blocks disappeared, and after the addition is complete, the reaction is refluxed for 4 hours.

[0055]The reaction liquid is cooled to room temperature, 1 L of water is poured, extraction is carried out with 100 ml petroleum ether for three times, the petroleum ether phases are combined and washed with water twice, the solvent is distilled off under reduced pressure, reduced pressure distillation is carried out to distil off fractions with a boiling point of lower than 95° C. / 700...

example 2

[0077]The structural formula of the chiral compound is as represented by the following formula:

[0078]Step 1: This step is the same as Step 1 of Example 1, except that bromocyclopentane is replaced with 3-propyl bromocyclopentane to prepare diethyl 2-(3-propylcyclopentyl) malonate.

[0079]Step 2. The Preparation Route is as Follows:

[0080]Specific Operation Procedures of the Preparation:

[0081]85.2 g (0.3 moles) of diethyl 2-(3-propylcyclopentyl) malonate prepared in Step 1 and 63.6 g (0.6 moles) of sodium carbonate are stirred together in 300 ml of ethanol and 100 ml of water overnight.

[0082]300 ml of water is added, the pH is adjusted to strongly acidic using dilute hydrochloric acid, extraction is carried out using 100 ml of toluene twice, washing is carried out with water twice, the solvent is distilled off under reduced pressure, and recrystallization is carried out using toluene to obtain 21.3 g of 2-(4-propylcyclopentyl) malonic acid being a white solid with a yield of 31%.

[0083]S...

example 3

[0089]The structural formula of the chiral compound is as represented by the following formula:

[0090]Step 1: This step is the same as Step 1 of Example 1, except that bromocyclopentane is replaced with bromocyclobutane to prepare diethyl cyclobutylmalonate:

[0091]Specific Operation Procedures of the Preparation:

[0092]30 g (0.18 moles) of diethyl malonate is dissolved in 200 ml of anhydrous ethanol, 5.1 g (0.22 moles) of sodium metal is added under nitrogen protection, 30 g (0.157 moles) of colourless liquid bromocyclobutane is added dropwise after sodium blocks disappeared, and after the addition is complete, the reaction is refluxed for 4 hours.

[0093]1 L of water is poured, extraction is carried out with 100 ml of petroleum ether for three times, the petroleum ether phases are combined and washed with water twice, the solvent is distilled off under reduced pressure, reduced pressure distillation is carried out to distil off fractions with boiling points of lower than 112° C. / 920 Pa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight fraction | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| crystal composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com