Footwear Article and Knitted Shoe Upper and Manufacturing Method Thereof

a technology of knitted uppers and footwear articles, which is applied in the direction of knitting, textiles and papermaking, weft knitting, etc., can solve the problems of increasing manufacturing costs, poor ventilation of conventional shoes made of leathers or polymers, and uncomfortable feeling, so as to improve wearing comfort, good ventilation, and high stretchability of knitted fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

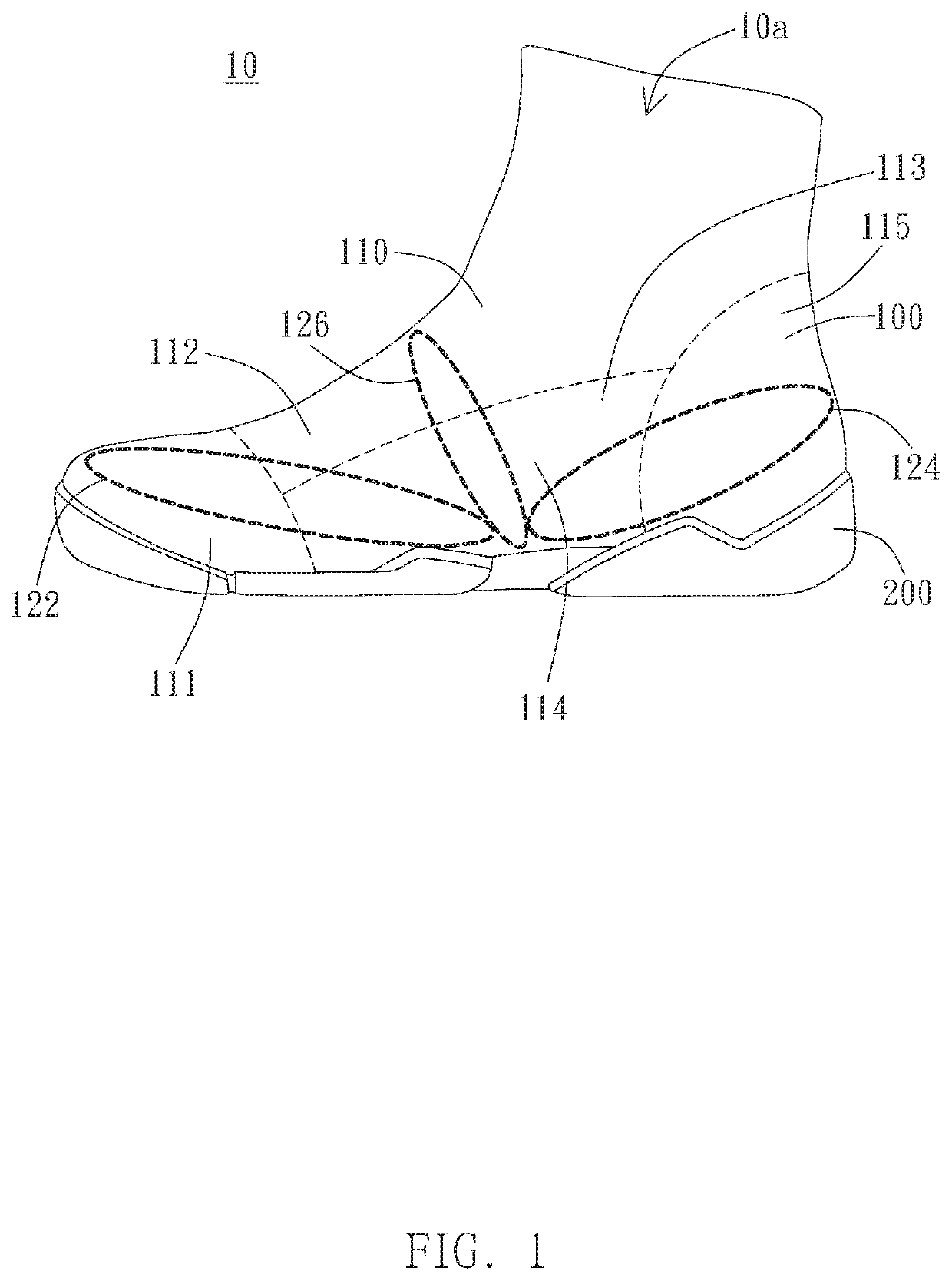

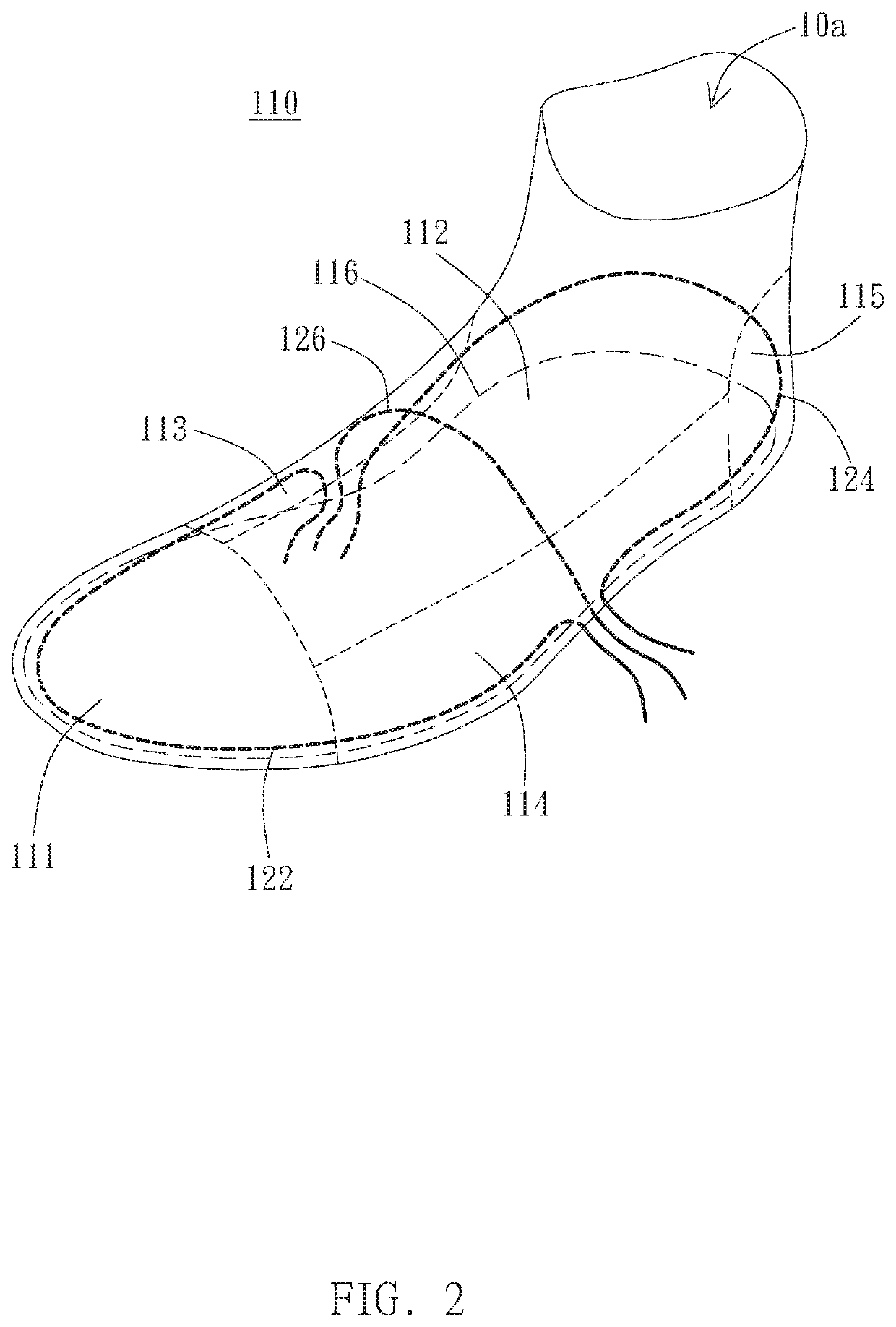

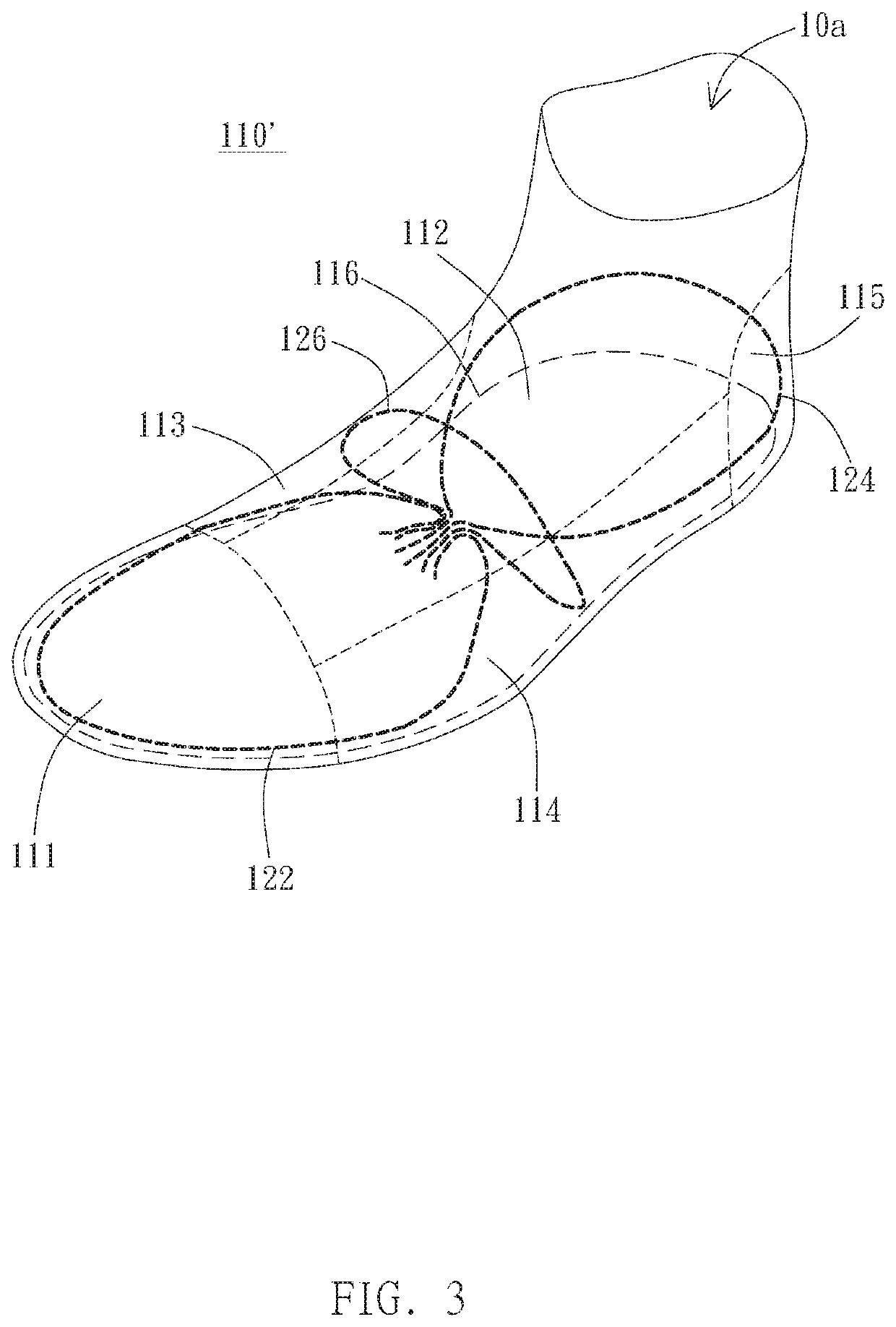

[0028]As shown FIG. 1, the footwear article 10 of the invention includes a knitted shoe upper 100 and a sole 200. The knitted shoe upper 100 is secured to the sole 200. The knitted shoe upper 100 includes a knitted fabric 110 and a plurality of inlaid strands (e.g. 122, 124, 126). The knitted fabric 100 includes a plurality of portions formed by knitting at least one yarn. The plurality of portions include a front portion 111, an instep portion 112, an inner lateral portion 113, an outer lateral portion 114, and a heel portion 115 together to enclose a three-dimensional space 10a for receiving a foot. The plurality of inlaid strands are inlaid in the knitted fabric 110 along different directions of the three-dimensional space 10a, so as to restrict relative displacements of the knitted fabric 110 toward the front portion 111, the heel portion 115, and the instep portion 112.

[0029]Specifically, the sole 200 can be any suitable sole and include functional elements for providing cushio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com