Flat steel semi-finished product, method for producing a component, and use thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

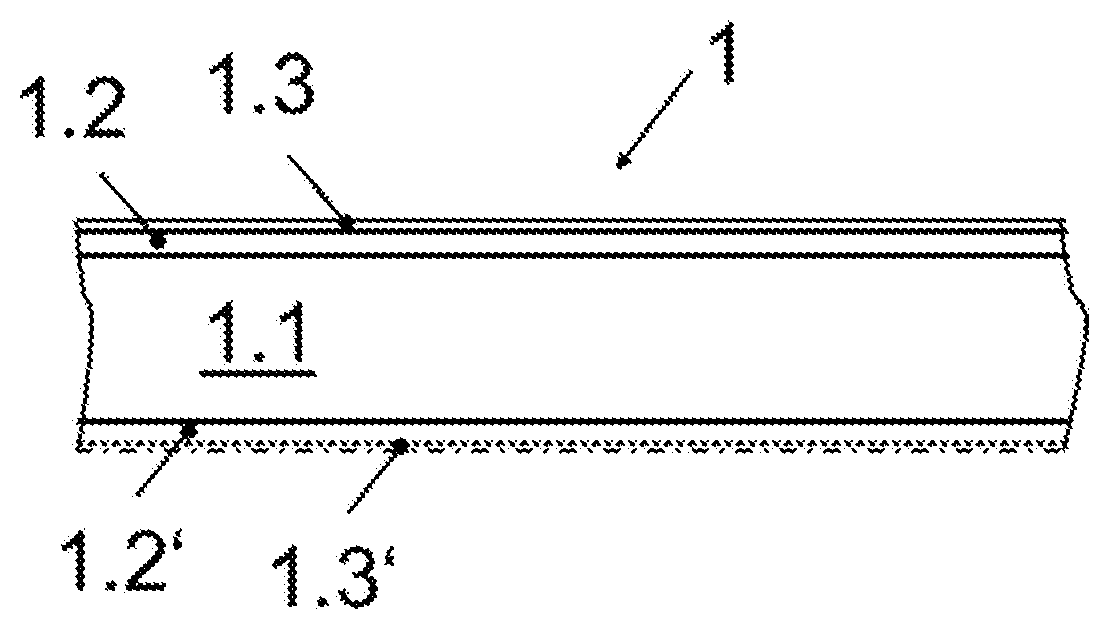

[0008]The inventor has found that it is possible, by the provision of at least a second layer of a soft steel alloy fully and cohesively bonded at least on one side to the first layer of a steel alloy having a martensitic microstructure and having a tensile strength of >1200 MPa and / or a hardness of >370 HV10. In some embodiments, the first layer of the steel alloy has a tensile strength of >1300 MPa and / or a hardness of >400 HV10, a tensile strength of >1400 MPa and / or a hardness of >435 HV10, a tensile strength of >1500 MPa and / or a hardness of >465 HV10, or even a tensile strength of >1600 MPa and / or a hardness of >490 HV10. Importantly, no direct contact with the first layer should be possible at least on one side when bonded to the soft steel alloy, such that the second layer of a soft steel alloy functions as a kind of functional layer. In the context of the invention, the soft steel alloy has a tensile strength of <600 MPa and / or a hardness of <190 HV10. In some embodiments, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com