This system has resulted in a modern marketplace with very high costs for the end-user.

Product technology and design is the main force driving these high costs.

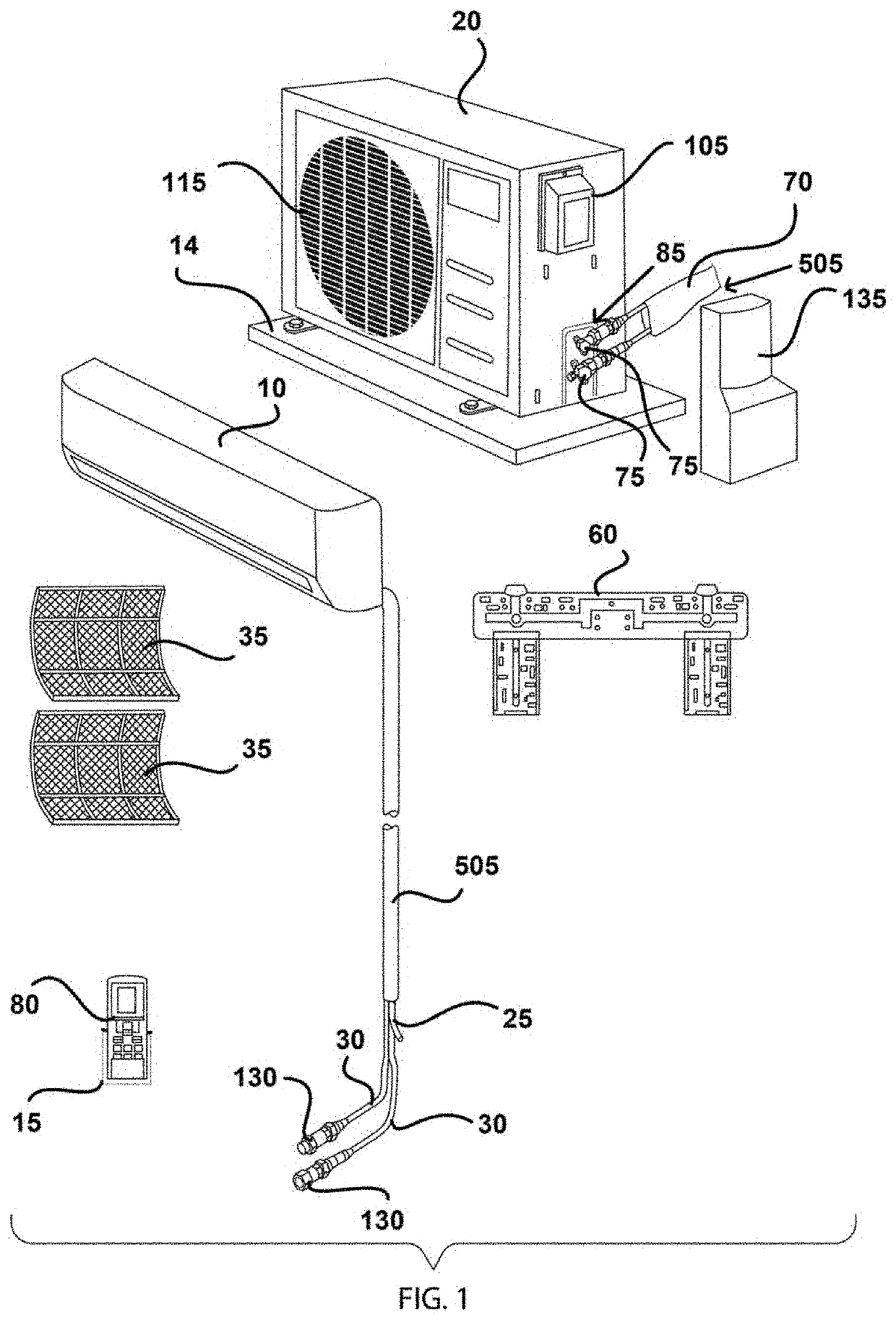

While the exact chemical formula has changed over the years, chemical refrigerants are the best technology by which to modify interior air temperature, but their presence in the system vastly complicates the installation process.

Socioeconomic factors further stratified air conditioners and heat pumps into expensive products requiring specialist assistance to utilize.

Non-certified installation often voids the warranty agreement.

The near monopoly some local companies held on certain brands reinforced the tendency to inflate price.

The design is fundamentally sound, but has its own problems.

The requisite compact footprint of the design forced a compromise in terms of capability.

The miniaturized coils and compressor condition air, but at decreased efficiency compared to traditional ducted installations.

Higher energy costs in the intervening years have exacerbated the problem.

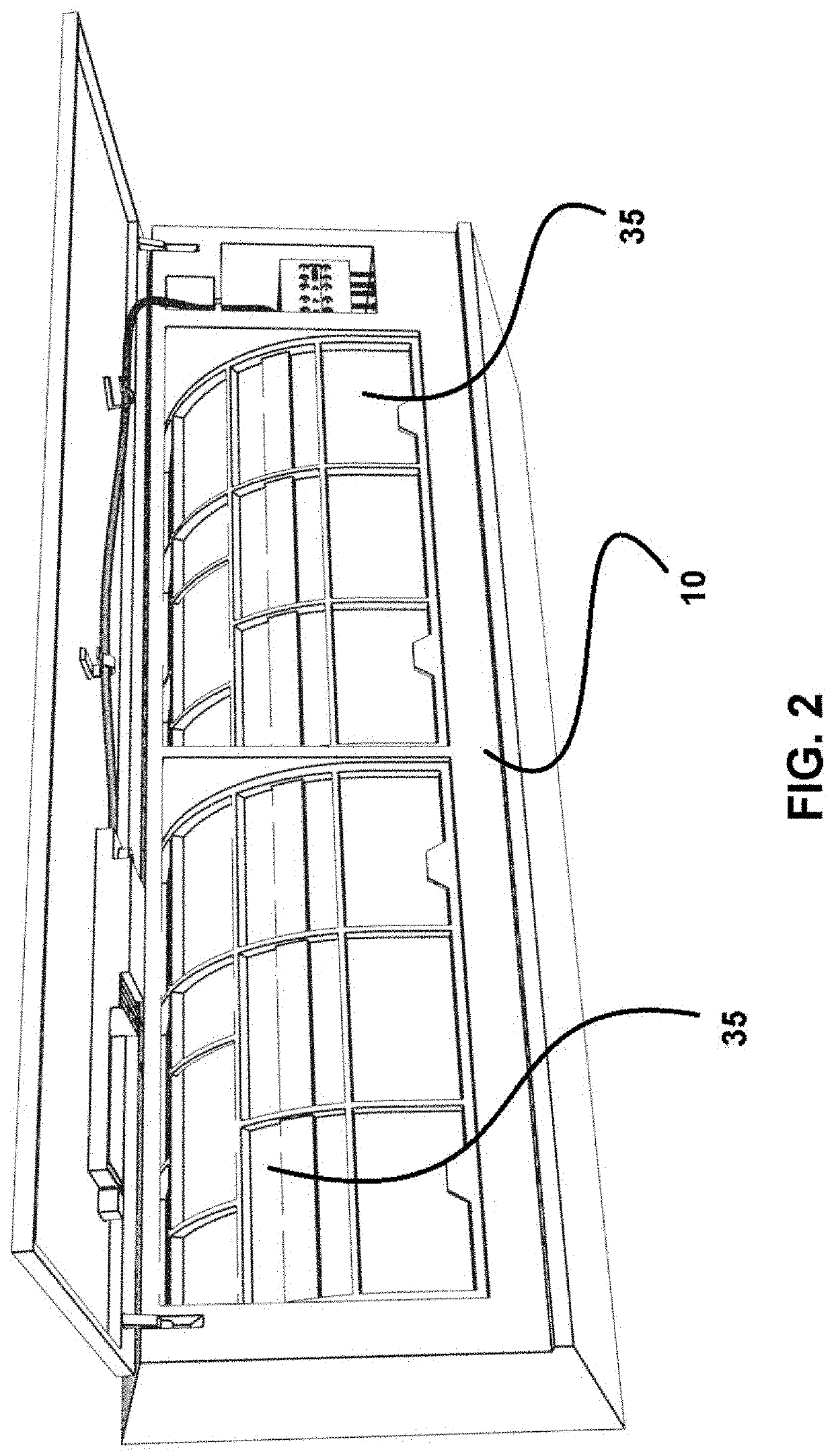

Air distribution is another problem with the room air conditioner.

The through-the-wall or window installation combined with a comparably simple fan limit the design's ability to move air effectively throughout an interior environment.

Unfortunately, the reliance on a standard wall outlet for power generation limited the product operating capacity.

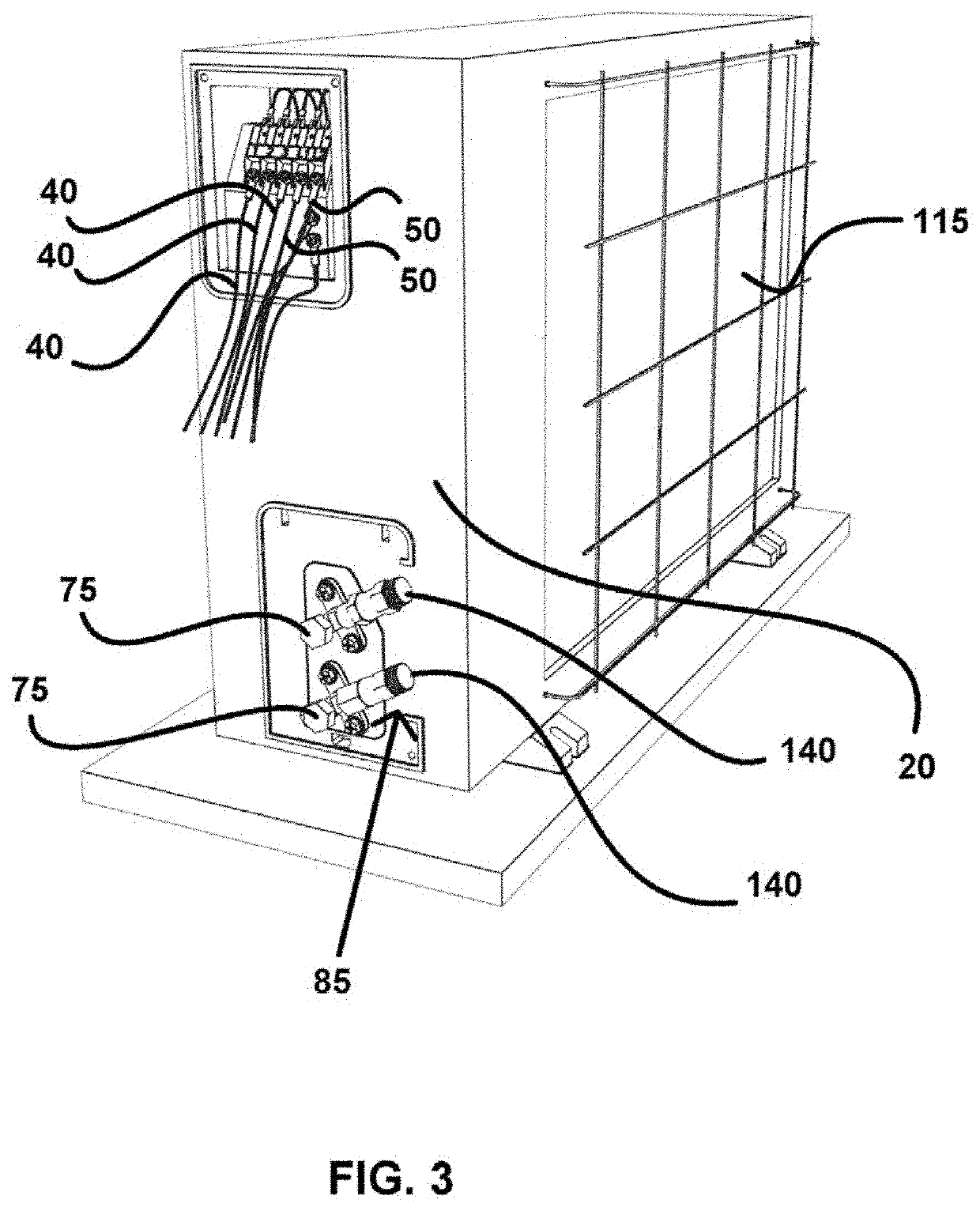

The refrigerant line coupling point was also inferior compared to conventional connections at the time and modern techniques.

Unfortunately, this design alone is inadequate to deal with the innumerable variables found in non-manufactured housing.

These make it difficult or impossible to use a pre-charged line of specific length with a ducted split system.

The downside of the Lingrey's ductless mini-split system is its reliance on a standard wall outlet for power, and its use of a locking lever-style dual-refrigerant connector.

The locking lever-style connection can operate effectively, but it is prone to leaking and can be difficult to detach without suffering refrigerant loss after the connection is made.

(a) Overall energy efficiency has been a problem with many of the room air conditioner designs. Efficiency optimization was not a major consideration for HVAC products when Brugler (1969) and Manganaro (1971) created their designs, but the market has changed considerably in the intervening four decades. Federal law holds manufacturers to higher standards than in the past. Eco-conscious and cost-concerned consumers also expect HVAC products to meet certain thresholds.

(b) The principle advantage a simpler HVAC product offers the end-user is the ability to utilize air conditioning technology without being forced to handle and / or manipulate chemical refrigerants. Virtually all previous designs strive towards this paradigm, but many fall short in one way or another. Some create connection points prone to leakage while others are difficult to disengage once the line is connected to the condenser. The former defeats the purpose of the product in the first place while the latter may merely prolong the period before a skilled technician is required to service the operating system.

(c) The trend to rely on a standard electrical wall outlet to power the unit eliminates the need for an electrician to wire the system, but can drastically reduce the potential capacity any such system might produce. This significantly limits the application of such products. As some of the designs require cutting through a wall for installation, the versatility offered by reliance on a wall outlet as opposed to conventional wiring is compromised.

(d) Inadequate airflow and uneven distribution are perennial problems for room air conditioners. The ability to install in an existing window frame grants flexibility, but severely limits airflow movement in a target zone. The aforementioned reliance on a wall outlet electrical connection also limits the power available to operate the interior fan. Ineffective conditioned air control serves to limit the applications in which such a product can reasonably function.

Flexible conduit tubing is designed to flex, however it is usually unable to flex near or beyond 90 degrees due to the nature of the seals of the flexible housing of the conduit tubing.

Unfortunately, conduit can be over-flexed during installation, especially by a novice, or when installation is performed in a hurry.

When flexible conduit (line-set) is bent too far, irreparable damage to the conduit occurs, often causing one or more holes in the conduit tubing.

In such cases, instead of the conduit bending and having a sealed tube within it, the tube is folded, which may cause breakage, or at the least, weaken the piping.

This causes a problem of the conduit piping having a crimp in the bend, restricting the flow inside.

A hard bend or crimp such as this can also cause holes, causing it to leak.

Breakage generally occurs when an improper bending technique is used, which can cause imperceptible defects in the metal when under stress.

Login to View More

Login to View More