Fluid circulation pump

a circulation pump and pump body technology, applied in pump components, positive displacement liquid engines, liquid fuel engine components, etc., can solve problems such as head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

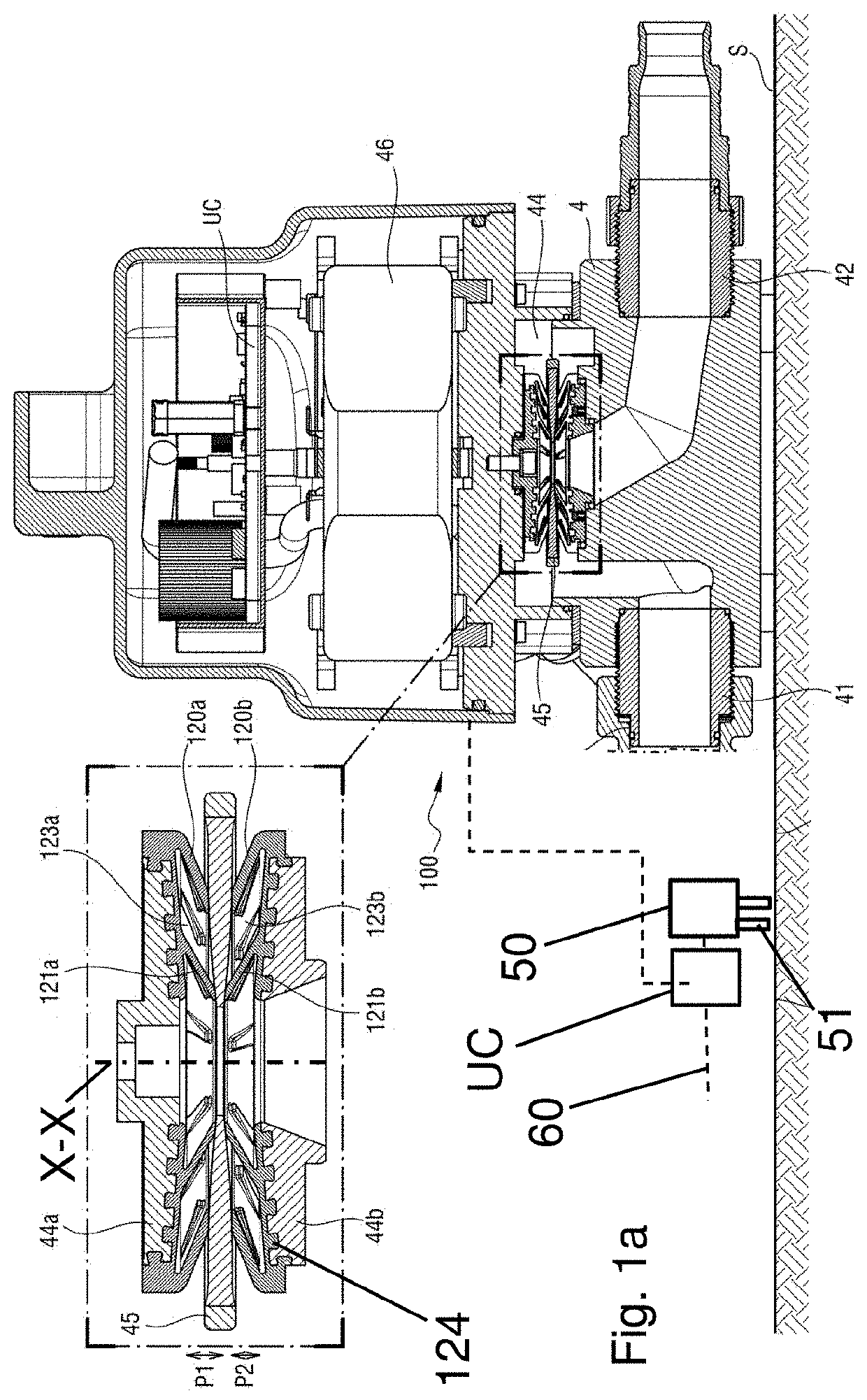

[0032]As mentioned above, the pump 100 of the invention includes a suction inlet 41 and a discharge outlet 42.

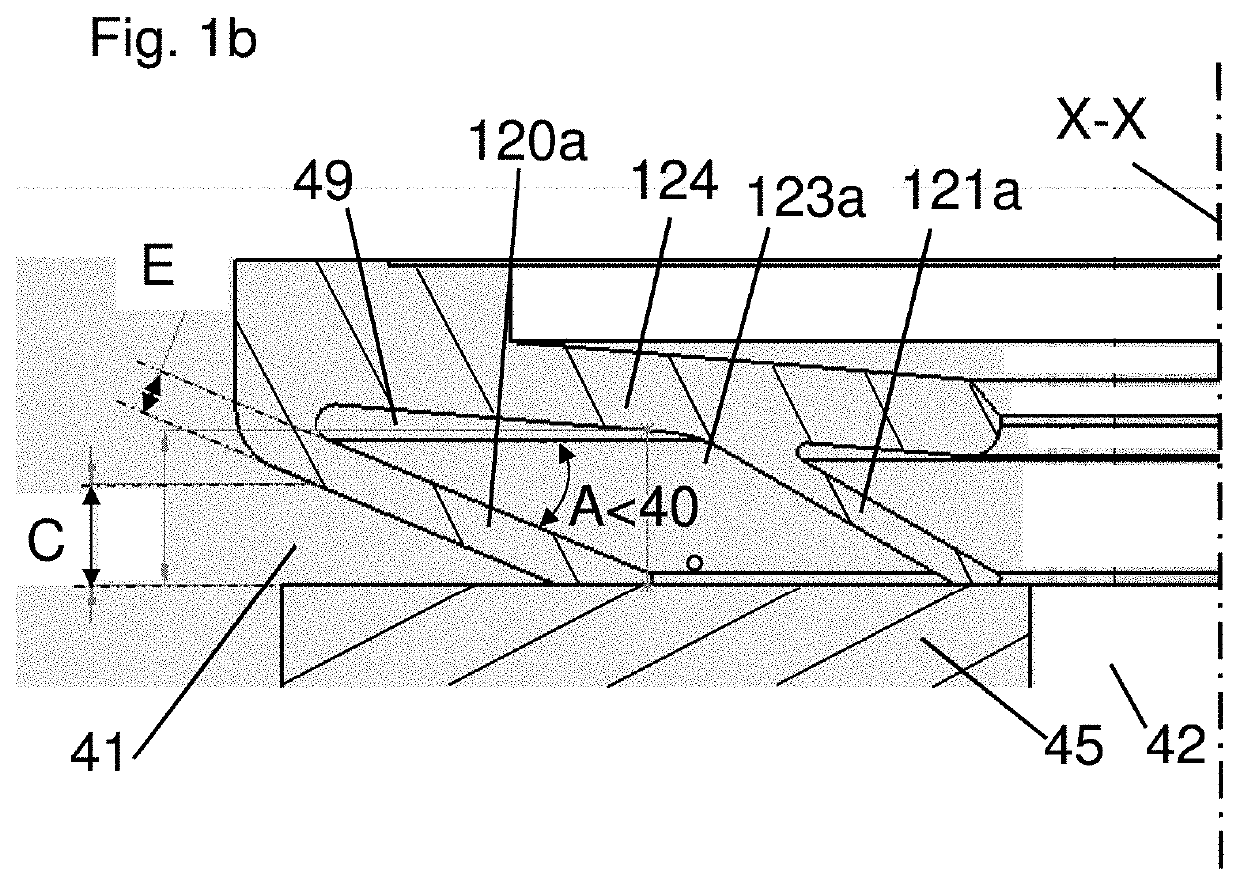

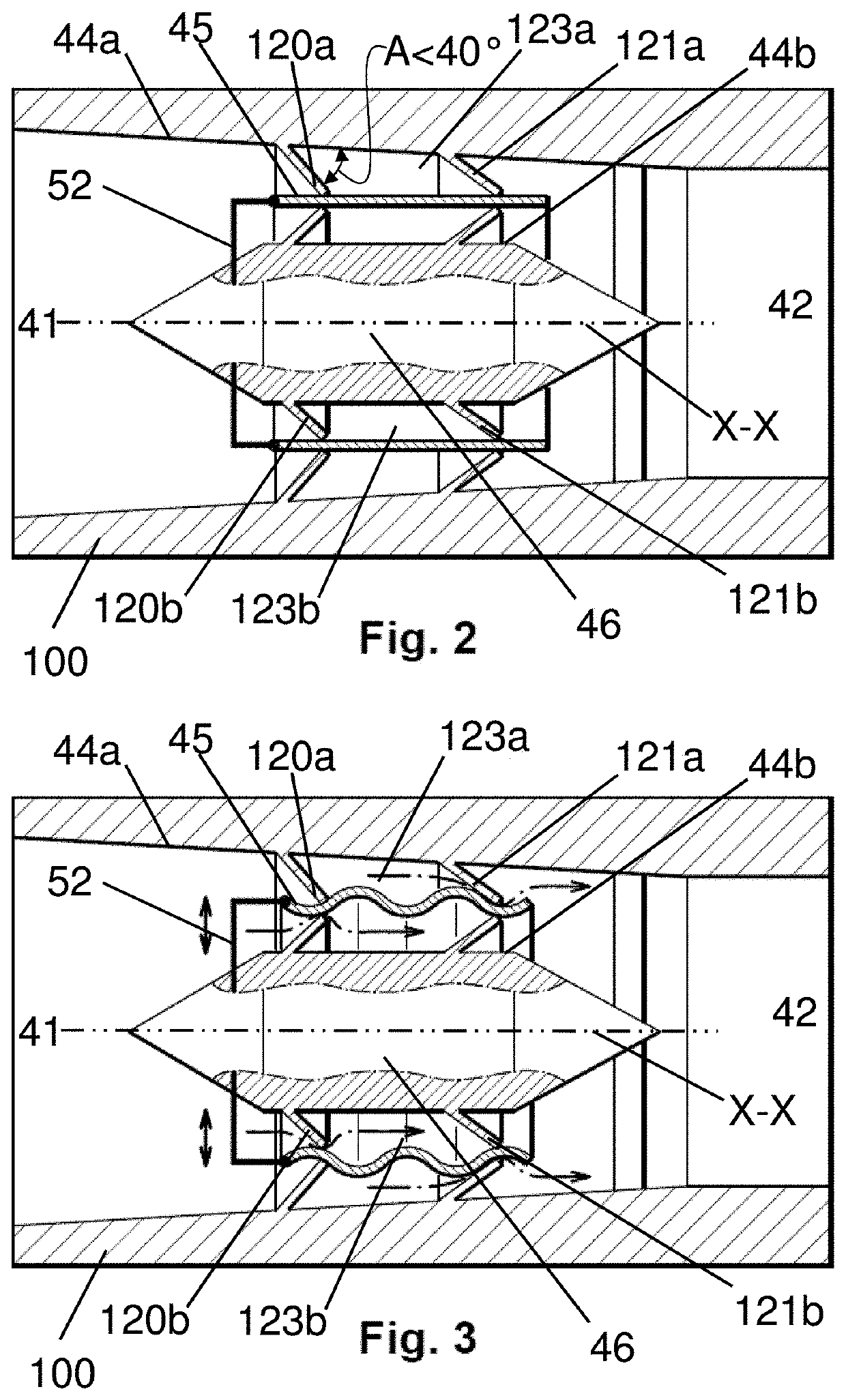

[0033]The pump includes a motor 46 that may be located either outside the chamber 44, as shown in FIG. 1a, or else inside the chamber, as shown in FIGS. 2 to 4.

[0034]In all embodiments, the motor 46 is mechanically connected to the movable part in order to be able to move it inside the chamber 44.

[0035]The pump 100 also has a first upstream lip 120a that is placed closer to the suction inlet 41 than it is to the discharge outlet 42, and a first downstream lip 121a that is placed closer to the discharge outlet 42 that it is to the suction inlet 41.

[0036]These first upstream and downstream lips 120a and 121a are placed between one of the sides of said movable part 45 and a first wall 44a of the chamber 44 so as to define a first space 123a between these first upstream and downstream lips 120a and 121a.

[0037]The arrangement of the lips defining the first passage 123a gives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com