Method and apparatus for recovery of metals with hydrocarbon-utilizing bacteria

a technology of hydrocarbon-utilizing bacteria and metal recovery, which is applied in the field of metal recovery, can solve the problems of sulfur-oxidizing organisms, ores that are often refractory, and are not amenable to conventional cyanidation treatment,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

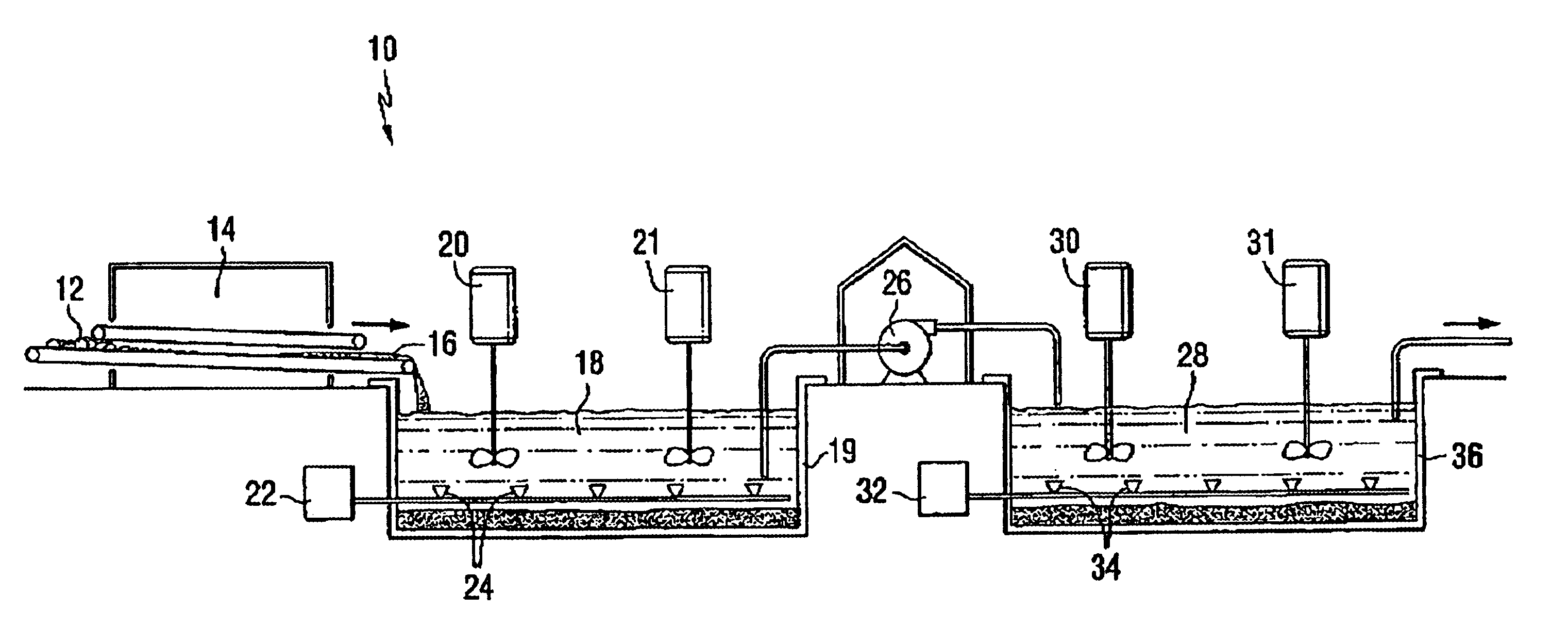

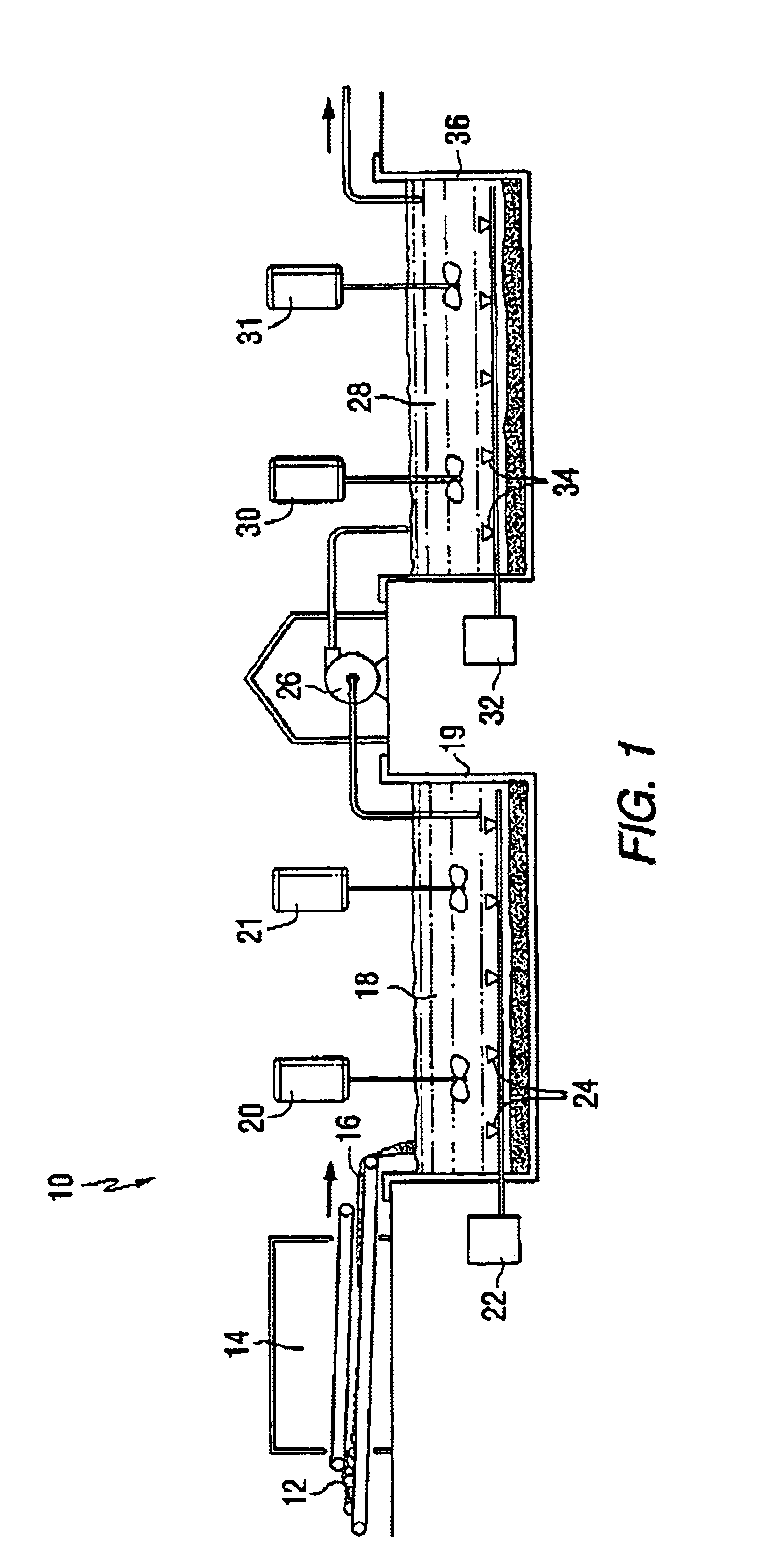

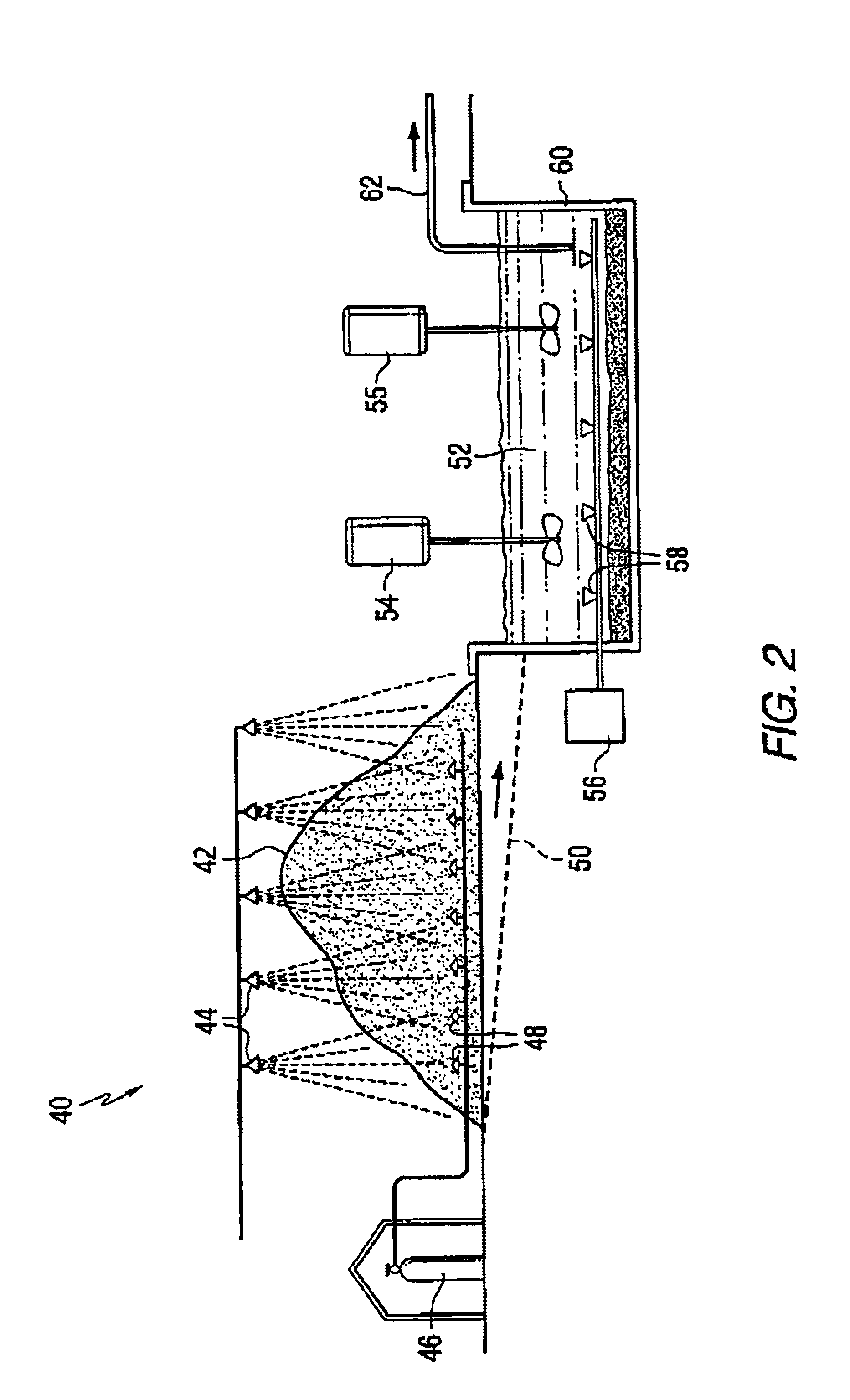

In accordance with the present invention, hydrocarbon-utilizing bacteria are used to liberate metals from metal-containing support materials such as mineral ores. The process may be used to biooxidize metals from ore-containing material using hydrocarbons under aerobic conditions only. Alternatively, the process may use anaerobic and aerobic processes to pretreat and biooxidize metals from ore-containing materials. The ore type and metal composition may determine which process would yield the most favorable metal recover. Under anaerobic conditions, the hydrocarbon may serve as an electron donor and carbon source while sulfate originating from the ore may serve as a final electron acceptor. Other electron acceptors may be used, such as nitrate, iron or carbon dioxide. Subsequently, aerobic hydrocarbon-utilizing organisms and their operative enzymes may be used to precipitate metals from solution, which may then be recovered.

In accordance with an embodiment of the present invention, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com