Composite pillow

a pillow and pillow body technology, applied in the field of composite pillows, can solve the problems of difficult to locate parts of different materials or hardnesses at proper positions, and achieve the effect of convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

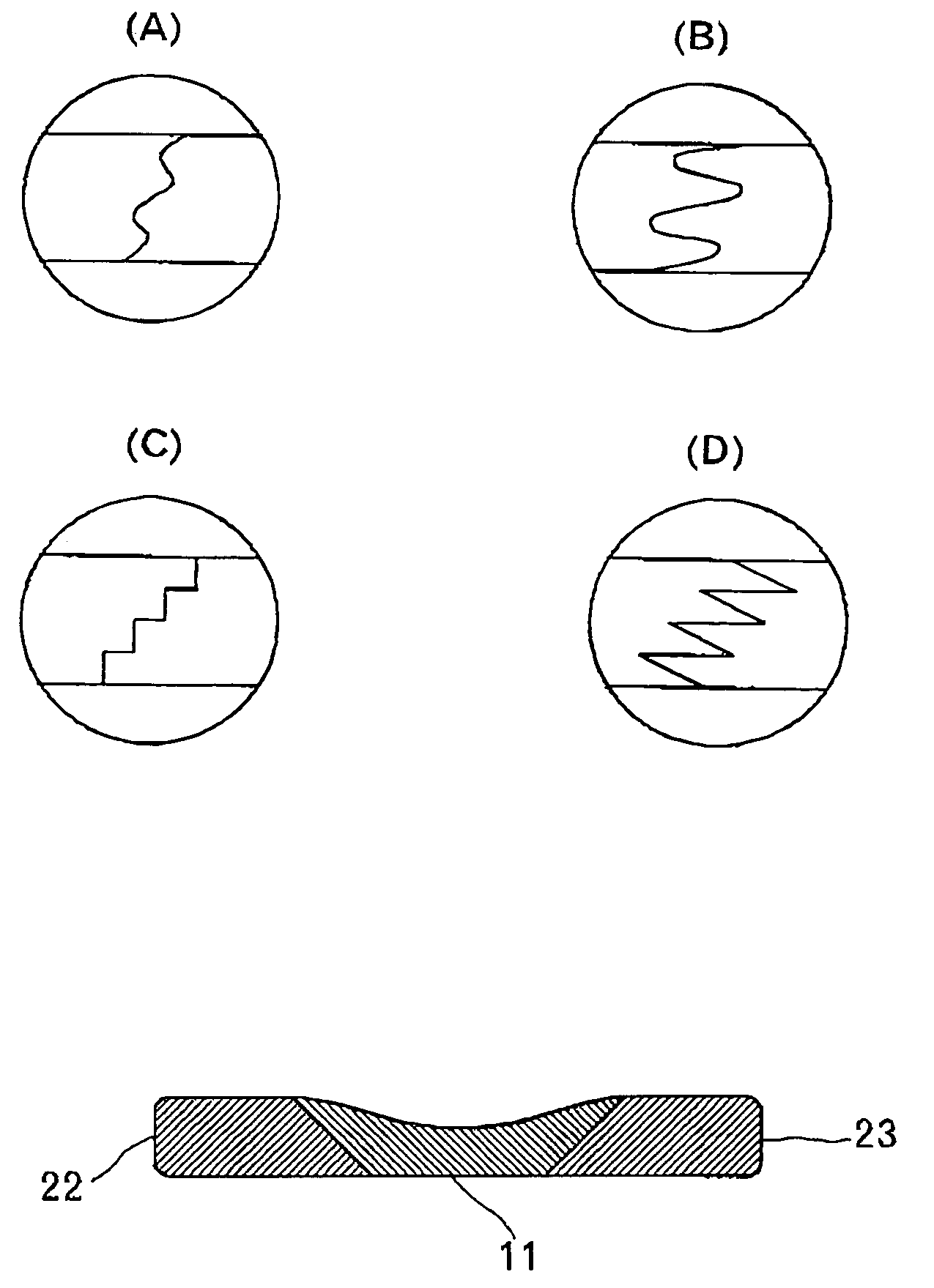

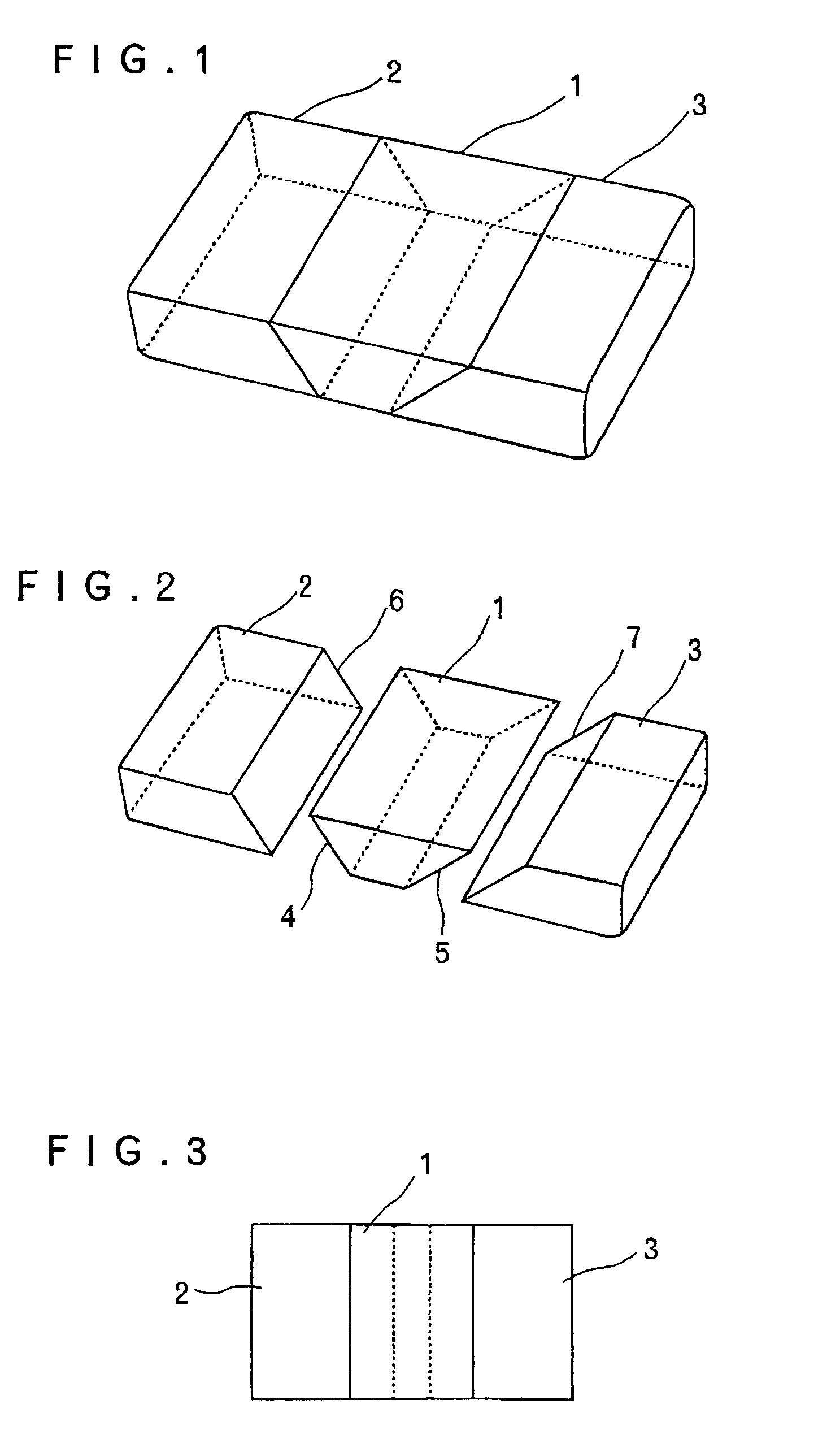

[0038]The composite pillow as shown in FIGS. 1–4, is divided into a central part 1, and a left holding part 2 and a right holding part 3 for holding the central part 1 by a face-to-face contact.

[0039]The central part 1 and the right and left holding parts 2, 3 are different in hardness or material. In this embodiment, urethanes of different hardnesses are employed. The hardnesses are expressed by the sinking into the pillow due to the weight of a human head. A soft urethane whose sinking ratio is 60% is employed for the central part 1 and a hard urethane whose sinking ratio is 20% is employed for the right and left holding parts 2, 3, thereby providing different hardnesses. This is just one example of a hardness combination, and other combinations are possible as a matter of course.

[0040]A urethane or polyethylene resin material, or a rubber-based natural material is suitable when the same material of different hardnesses is employed as in this embodiment.

[0041]While an integrally ...

fourth embodiment

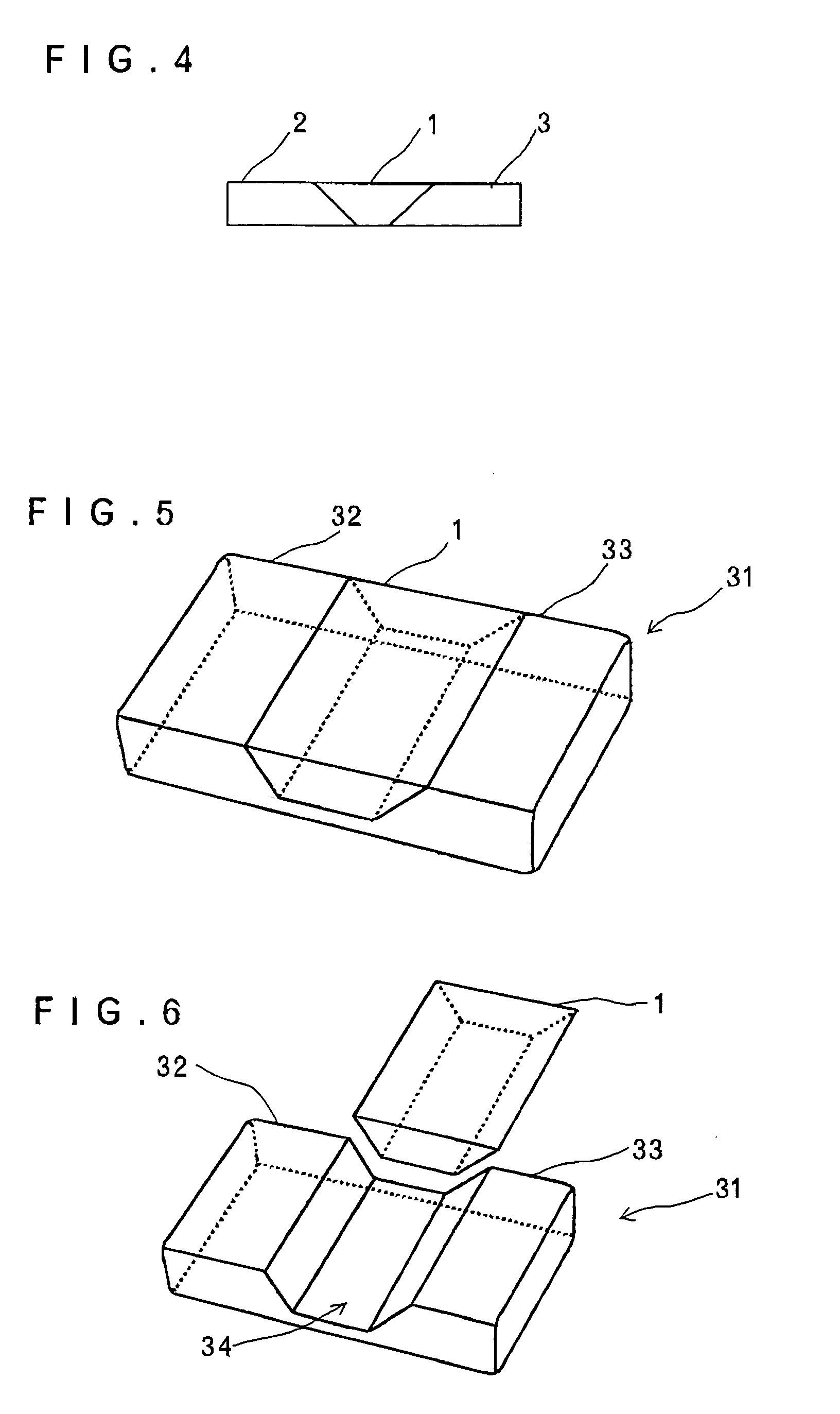

[0053]FIG. 18A and FIG. 19A show use of a pillow of the third or fourth embodiment when lying on the back. If a head is put at the center of the pillow at with the head located on the head top side central portion 12, the neck is located on the neck side central portion 11. In this state, since the neck side central portion 11 is made of a rather hard urethane whose sinking ratio is 40% and the head top side central portion 12 is made of a soft urethane whose sinking ratio is 60%, the neck side central portion 11 supports the neck without sinking deeply, thereby preventing the cervical vertebrae from being damaged by the use of the pillow.

[0054]Also, when using the pillow while lying on the side, the position of the head is preferably maintained higher than the case when lying on the back, for cervical vertebrae protection. The composite pillow according to the third and the fourth embodiments, in which the right and left holding parts 22, 23 employ a hard urethane whose sinking rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com