Floor structure of vehicle body

a technology of vehicle body and floor structure, which is applied in the direction of roofs, transportation and packaging, vehicle arrangements, etc., can solve the problems of easy deformation at the joint part, ineffective propagation of collision load f inputted into the side sill due to a side collision, and easy deformation at the narrow portion of the lateral, so as to reduce the weight of the vehicle, effectively propagate to the cross members, and strengthen rigidity against external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0029]With reference to drawings, explanations will be given on a floor structure of a vehicle body according to a first embodiment of the present invention.

[0030]Note that rear and front directions (or a longitudinal direction), and right and left directions (or a lateral direction) used in the explanation are based on a condition in which a floor panel that is a principle component of the floor structure of the vehicle body is provided with a pair of right and left side sills and a pair of rear and front cross members, both of which constitutes the vehicle body. These directions are based on a driver's view direction, as well.

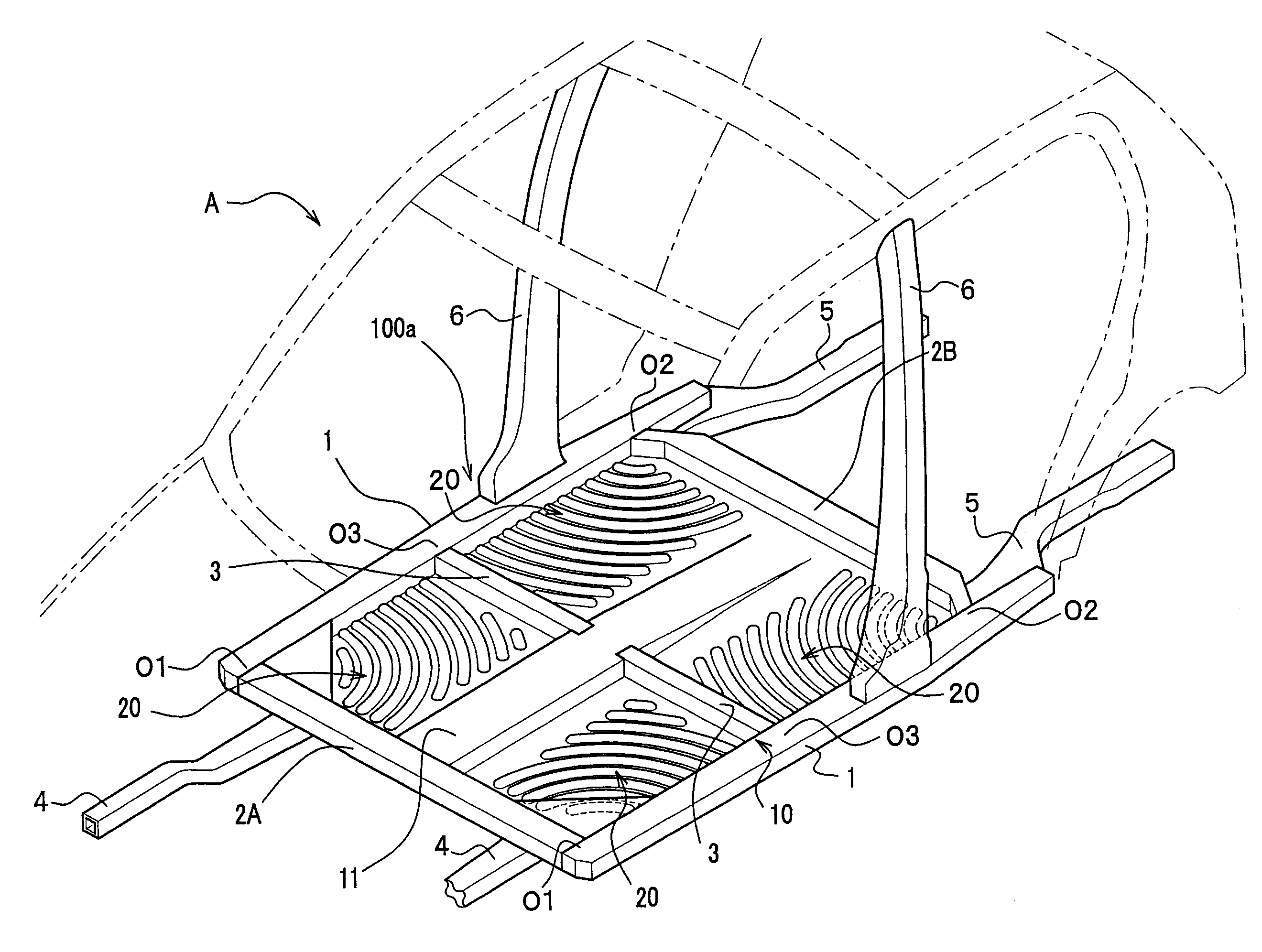

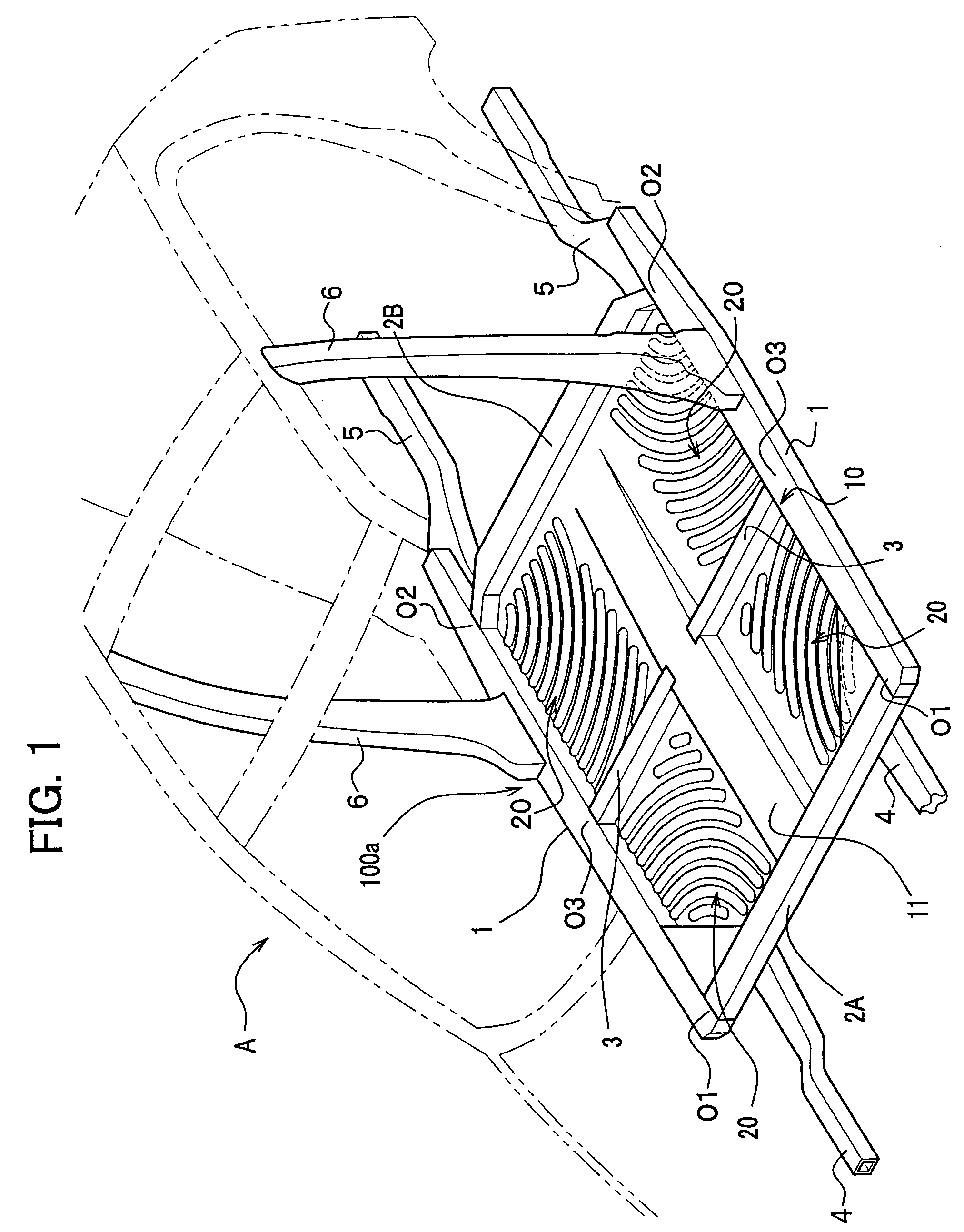

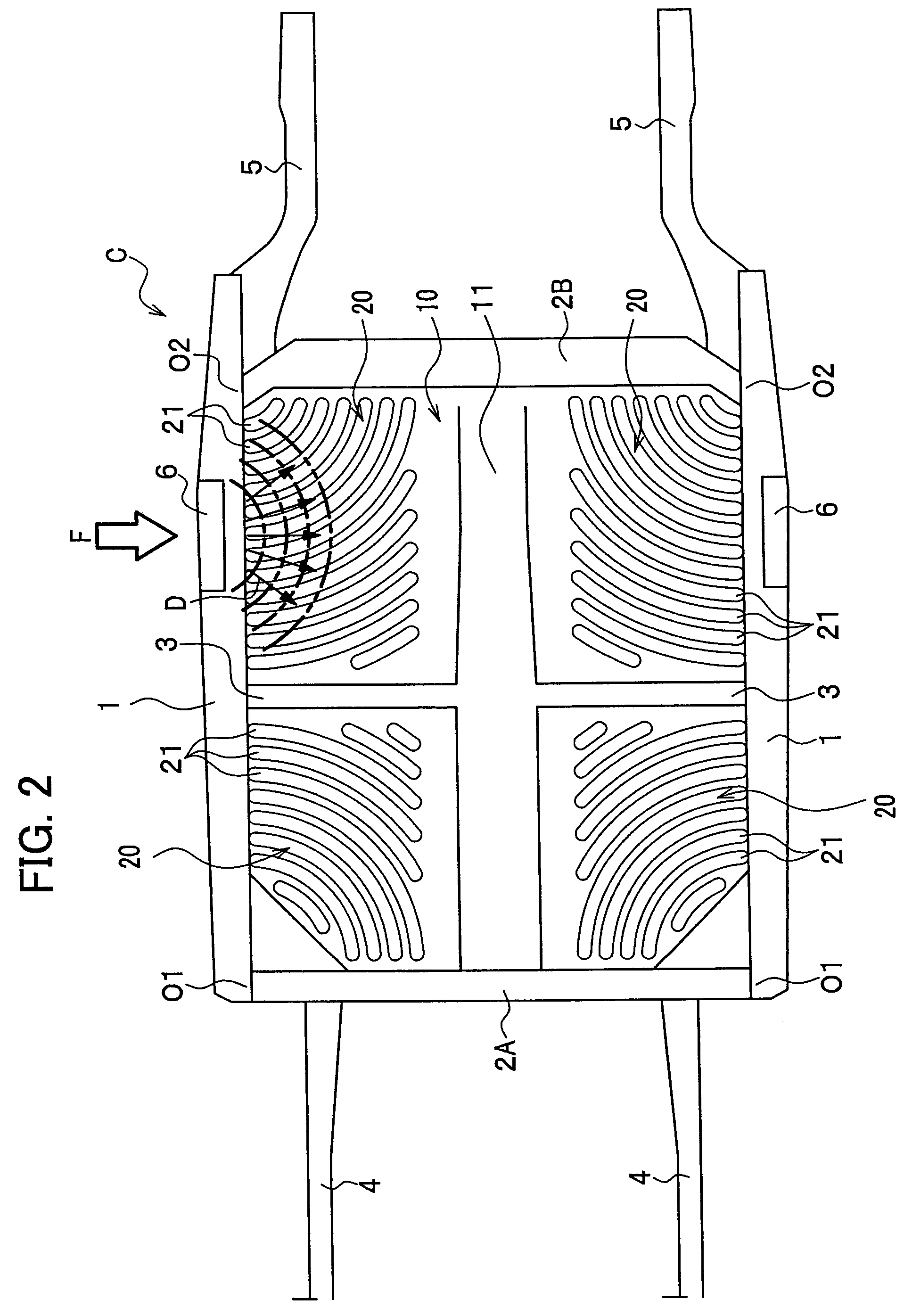

[0031]FIG. 1 is a perspective view of a vehicle body structure around a vehicle compartment to explain details of the floor structure of the vehicle body according to the first embodiment. FIG. 2 is a plan view showing principle components of the vehicle body.

[0032]As shown in FIG. 1 the floor structure of the vehicle body 100a includes a pair of right and le...

second embodiment

[0054]With reference to drawings, explanations will be given on a floor structure of a vehicle body according to a second embodiment.

[0055]Note that, in the explanations on the second embodiment, the same components of the second embodiment as those of the first embodiment are denoted by the same numeral references of the first embodiment.

[0056]FIG. 7 is a general perspective view showing the floor structure of a vehicle body 100b according to the second embodiment. FIGS. 8A and 8B are partially enlarged perspective views. FIG. 8A is a right front side of the floor structure of the vehicle body 100b, and FIG. 8B is a left front side thereof. As in the first embodiment, rear and front directions (or longitudinal direction), and right and left directions (or lateral direction) used in the explanation in the second embodiment are based on a condition in which a floor panel 10 that is a principle component of the floor structure of the vehicle body is provided with a pair of right and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com