Dental implant and head for a compaction drill

a technology of dental implants and compaction drills, which is applied in the field of dental implants and beading for compaction drills, can solve the problems of inconvenience and expense of extra surgery, metal portion of implants exposed above the gum line, and disadvantages of aesthetics, so as to promote bonding with bone tissue, promote stress dispersion, and promote the effect of tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Hereinafter, various embodiments of the present invention will be explained in more detail with reference to the accompanying figures, however, it is understood that the present invention should not be limited to the following preferred embodiments set forth herein.

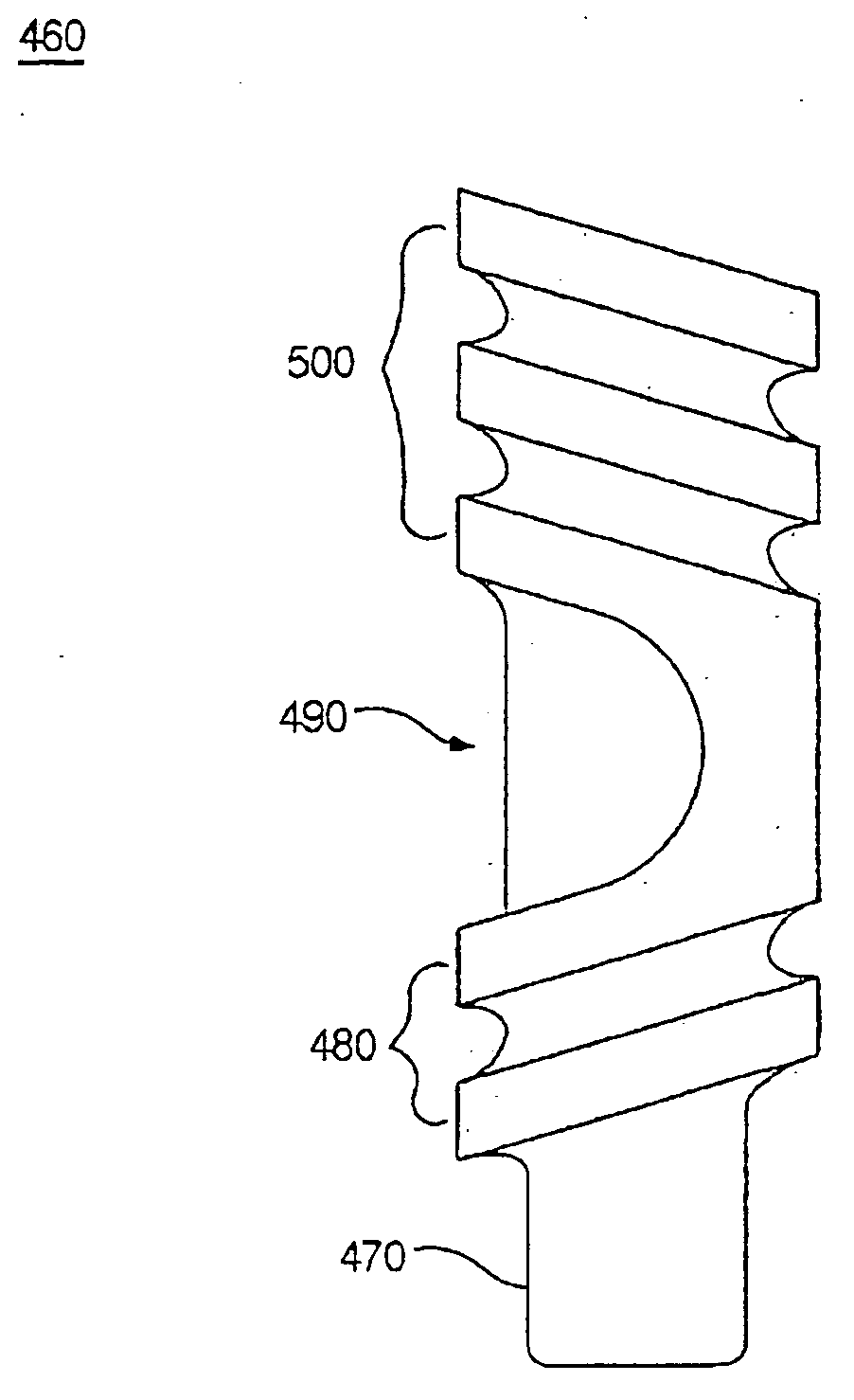

[0064]FIG. 5 is a perspective view for showing a dental implant according to one embodiment of the present invention and FIG. 6 is an enlarged side view for illustrating the dental implant in FIG. 5.

[0065] Referring to FIGS. 5 and 6, a dental implant 200 according to the present embodiment includes am upper abutment portion 210, a lower fixture portion 220 and a settling portion 230 formed between the abutment portion 210 and the fixture portion 220. Those portions 210, 220 and 230 are integrally formed. A crown cap 240 is mounted on the abutment portion 210 and adapted as the artificial crown.

[0066] The surface of the abutment portion 210 is generally machined. The surfaces of the fixture and the settling porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com